Preparation method of heat-conducting polyvinyl chloride composite material with microwave absorption characteristic

A polyvinyl chloride and microwave absorption technology is applied in the preparation field of thermally conductive polyvinyl chloride composite materials. The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

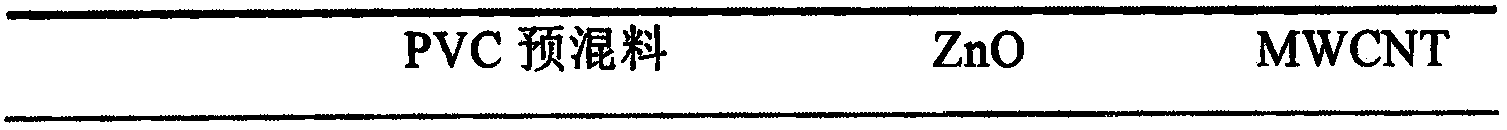

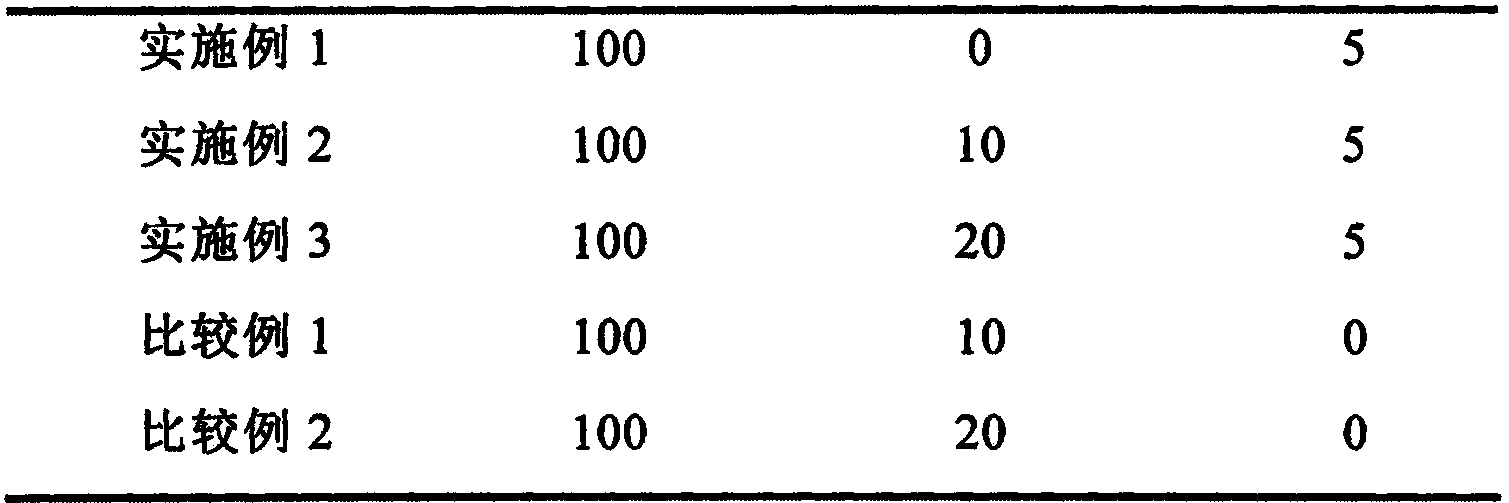

[0022] The formula is shown in Table 1.

Embodiment 4

[0036] A method for preparing a thermally conductive polyvinyl chloride composite material with microwave absorption properties, comprising the following steps:

[0037] (1) Add 100 parts by weight of PVC resin, 2 parts by weight of heat stabilizer, 0.5 parts by weight of lubricant, 0.1 part by weight of processing aid and 30 parts by weight of plasticizer in the high-speed kneader, and wait until the materials are completely plasticized. material, and the discharge temperature is controlled at 80°C to obtain a PVC premix, wherein the degree of polymerization of the PVC resin is 800; the heat stabilizer is organotin maleate; the lubricant is polyethylene oxide; the processing aid is monohard Glyceryl esters; the plasticizer is diethyl phthalate;

[0038] (2) Add 100 parts by weight of PVC premix in the haake mixer, 3 parts by weight of multi-walled carbon nanotubes with a diameter of 5 nm and a length of 0.5 μm, and 5 parts by weight of zinc oxide with a particle diameter of 0...

Embodiment 5

[0040] A method for preparing a thermally conductive polyvinyl chloride composite material with microwave absorption properties, comprising the following steps:

[0041] (1) Add 100 parts by weight of PVC resin, 5 parts by weight of heat stabilizer, 2 parts by weight of lubricant, 4 parts by weight of processing aid and 60 parts by weight of plasticizer in the high-speed kneader. material, and the discharge temperature is controlled at 100°C to obtain a PVC premix, wherein the degree of polymerization of the PVC resin is 2000; the heat stabilizer is lead dibasic phosphite; the lubricant is calcium stearate; the processing aid is acrylic acid methyl ester; the plasticizer is di-n-octyl phthalate;

[0042] (2) Add 100 parts by weight of PVC premix in haake mixer, 8 parts by weight of diameter is 100nm, multi-walled carbon nanotubes with length of 10 μm, 30 parts by weight of particle diameter is zinc oxide of 2 μm, temperature of mixer at 170°C, and mixed for 5 minutes, a therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com