Semisynthetic organic heat carrier

A semi-synthetic and carrier technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of human body and environmental hazards, short service life, low thermal stability, etc., and achieve safe and reliable combustion, uniform heating, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

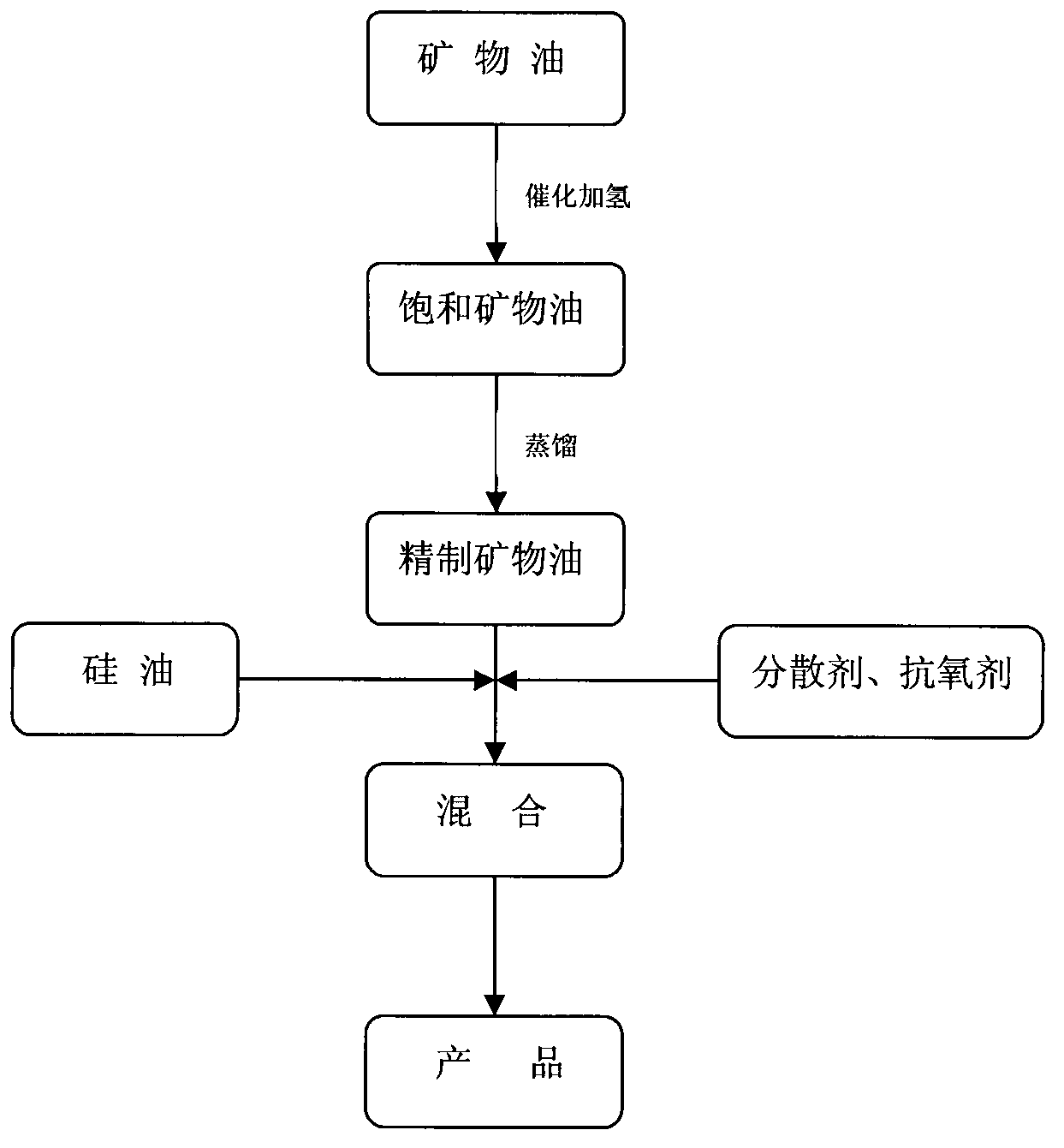

Method used

Image

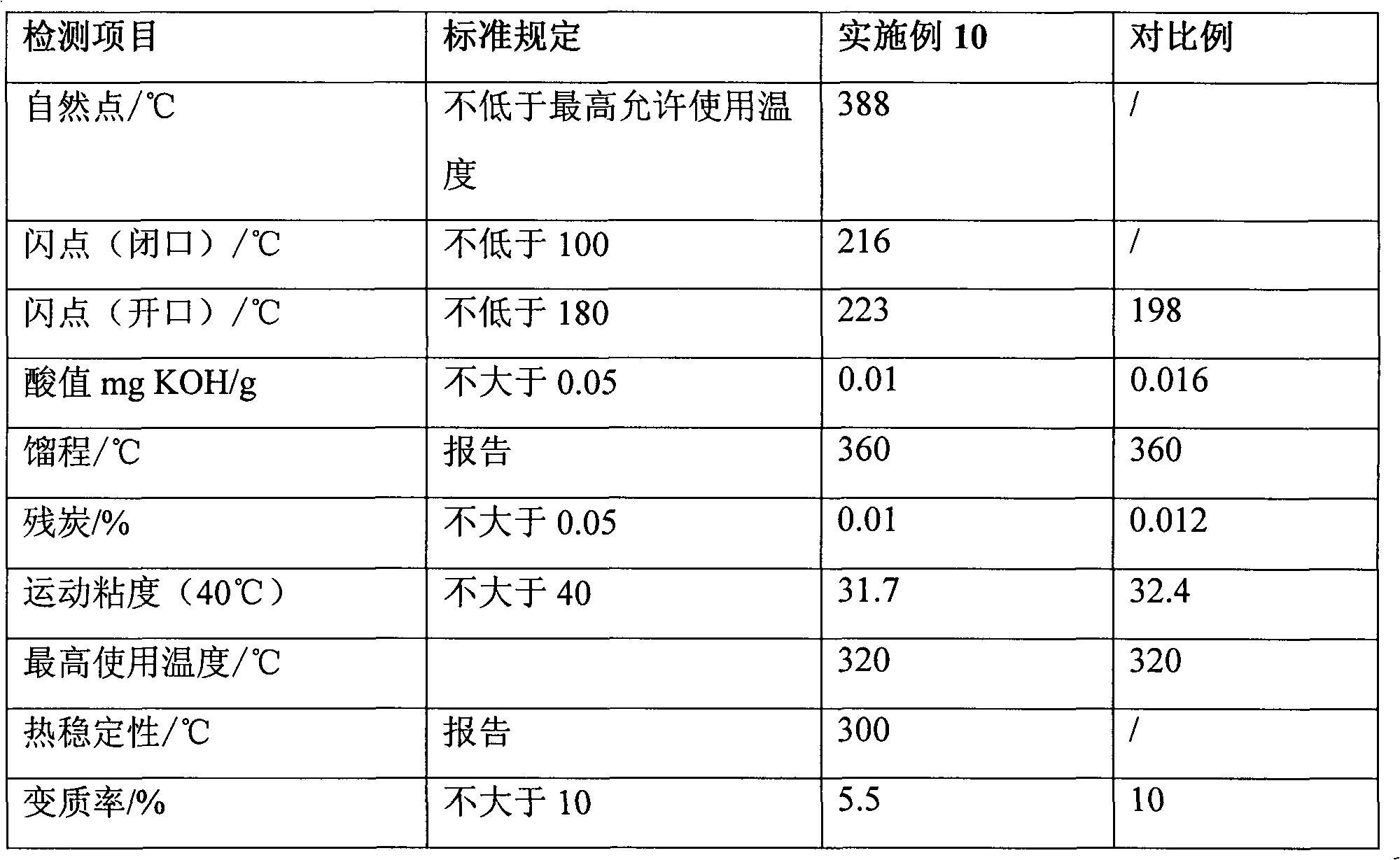

Examples

Embodiment 1

[0022] 85 grams of refined base oil, 5.2 grams of methyl silicone oil, 1.0 grams of ethyl silicone oil, 0.8 grams of phenyl silicone oil, 1.0 grams of methyl trifluoropropyl silicone oil, 6.5 grams of dispersant TX-10, 0.5 grams of high temperature antioxidant 1010 , mixed and stirred at 75°C and normal pressure to obtain a uniform and transparent semi-synthetic organic heat carrier product.

Embodiment 2

[0024] Mix and stir 99.6 grams of refined base oil, 0.1 grams of methyl silicone oil, 0.05 grams of dispersant L-18, and 0.25 grams of high-temperature antioxidant 4010NA under normal temperature and pressure to obtain a uniform and transparent semi-synthetic organic heat carrier product.

Embodiment 3

[0026] 90 grams of refined base oil, 1.0 methyl vinyl silicone oil, 0.5 grams of methyl hydroxy silicone oil, 1.5 grams of ethyl hydrogen silicone oil, 0.4 grams of hydroxyl hydrogen silicone oil, 0.1 grams of cyanosilicone oil, 1.0 grams of dispersant TX-5, 5.5 grams of high-temperature antioxidant DTBHQ were mixed and stirred under normal temperature and pressure to obtain a uniform and transparent semi-synthetic organic heat carrier product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com