Thin-film transistor array substrate and manufacturing method and electronic devices thereof

A transistor array and thin film field effect technology, applied in the field of liquid crystal display, can solve the problems of complex manufacturing process and high manufacturing cost, achieve high mobility, reduce manufacturing time, and reduce the number of patterning processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

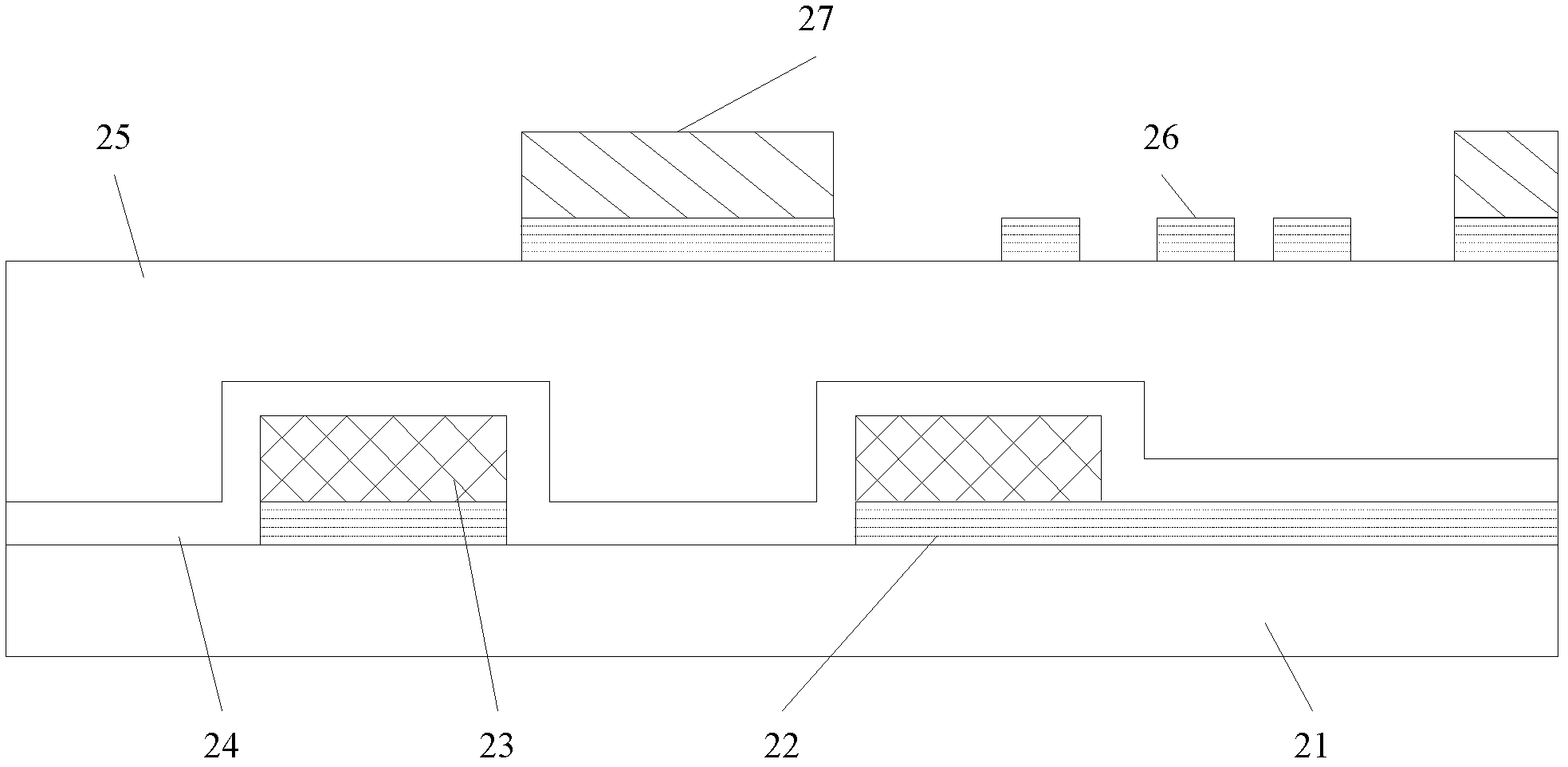

[0061] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0062] Embodiments of the present invention aim at the problems that the manufacturing process of the transparent oxide TFT array substrate is relatively complicated and the manufacturing cost is high in the prior art, and provide a thin film field effect transistor array substrate and its manufacturing method, and an electronic device, which adopts three-time patterning process that is The transparent oxide TFT array substrate can be produced, the manufacturing process of the transparent oxide TFT array substrate is simplified, the manufacturing time is shortened, and thus the production cost is reduced.

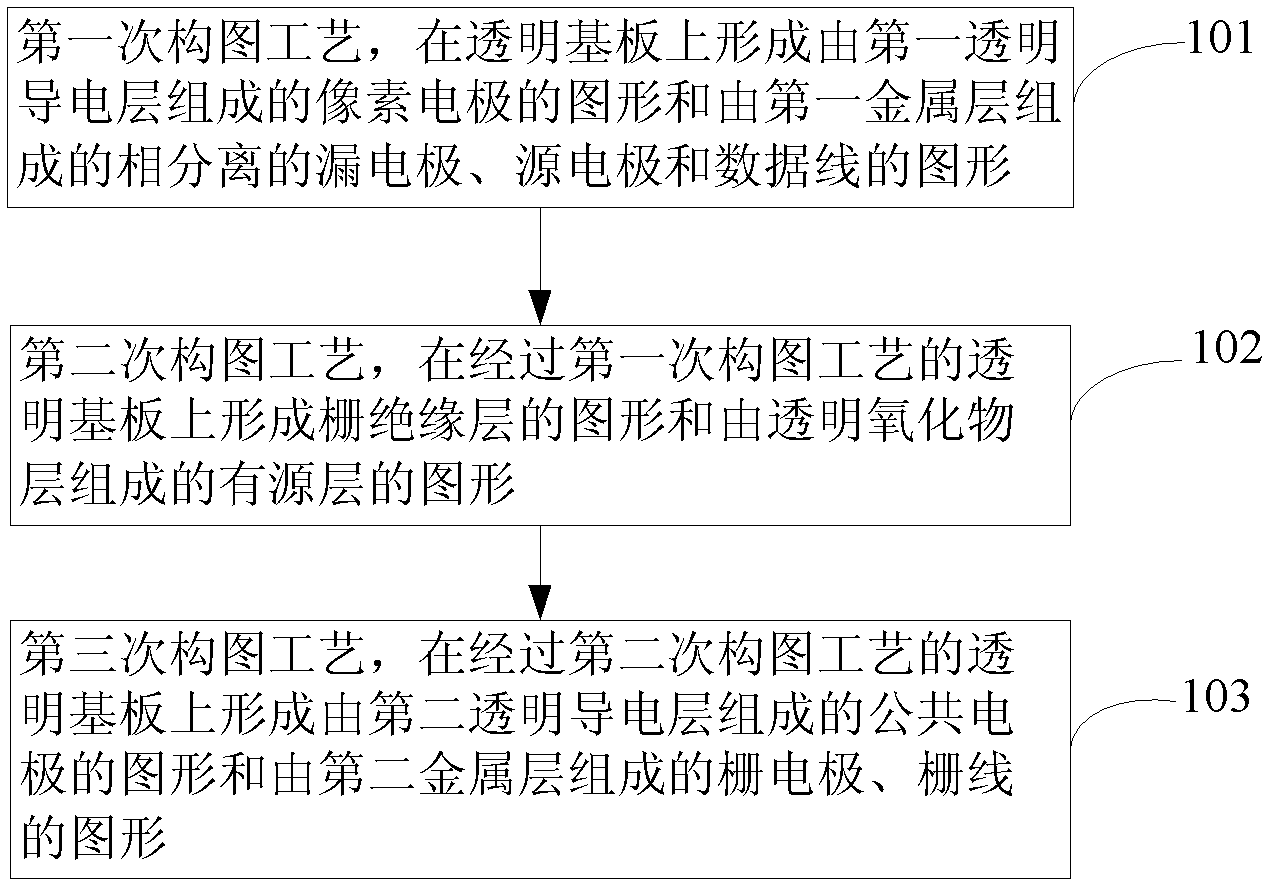

[0063] figure 1 It is a schematic flow diagram of a manufacturing method of a thin film field effect transistor array substrate ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com