Non-woven fabric for filter, and process for production thereof

A manufacturing method, non-woven technology, applied in membrane filters, chemical instruments and methods, separation methods, etc., can solve problems such as pressure loss, inability to exert adsorption capacity, and difficulty in covering the surface of fibers thinly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, although an Example etc. demonstrate this invention in more detail, this invention is not limited to these. In addition, the measurement method of each characteristic value in an Example is shown below. In addition, in the following examples etc., "normal temperature" means "15-25 degreeC", and "%" means "% by weight" unless otherwise specified. The peptide concentration was calculated by converting the amount of nitrogen into the amount of protein after measuring the amount of nitrogen by the Kjeldahl method.

manufacture example 1)

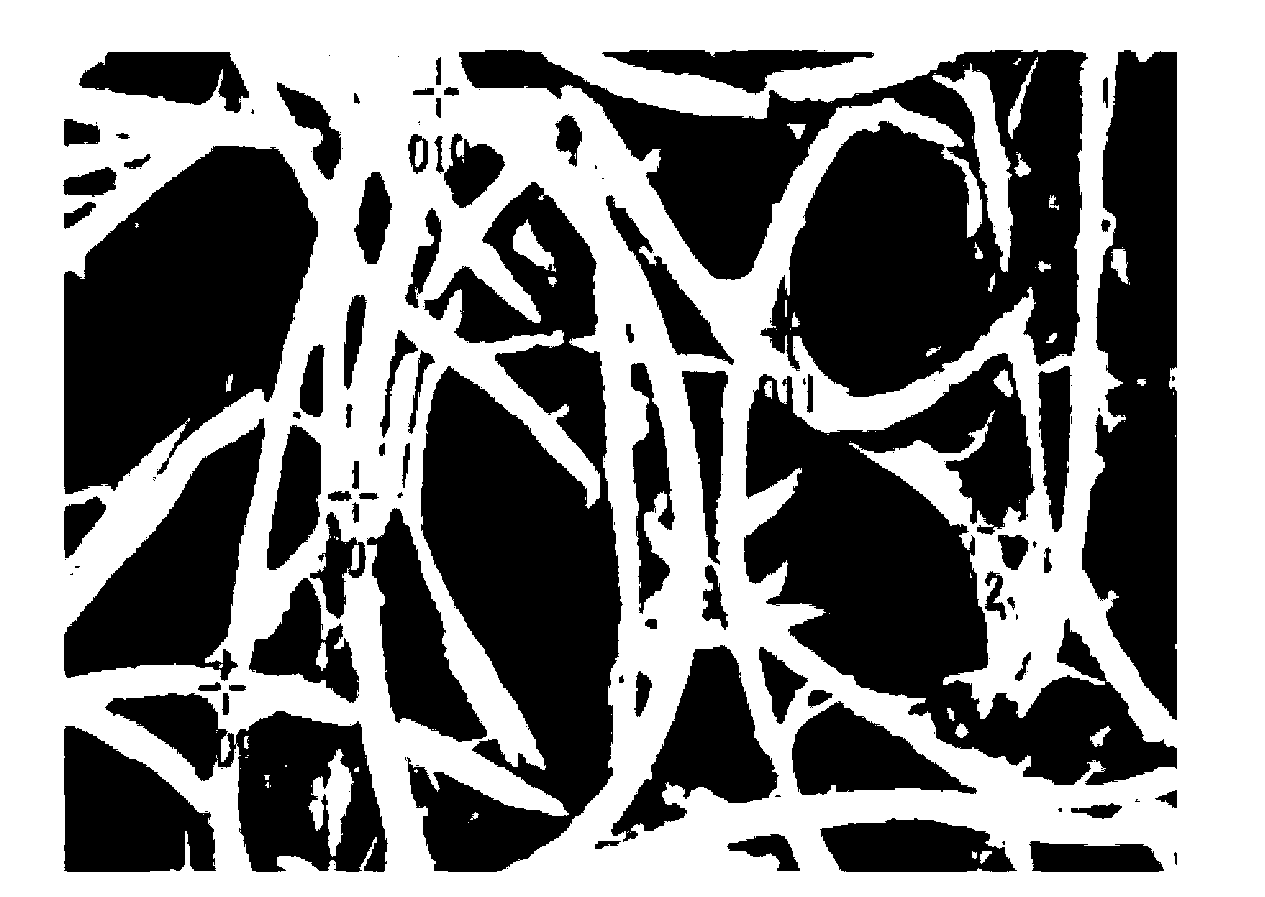

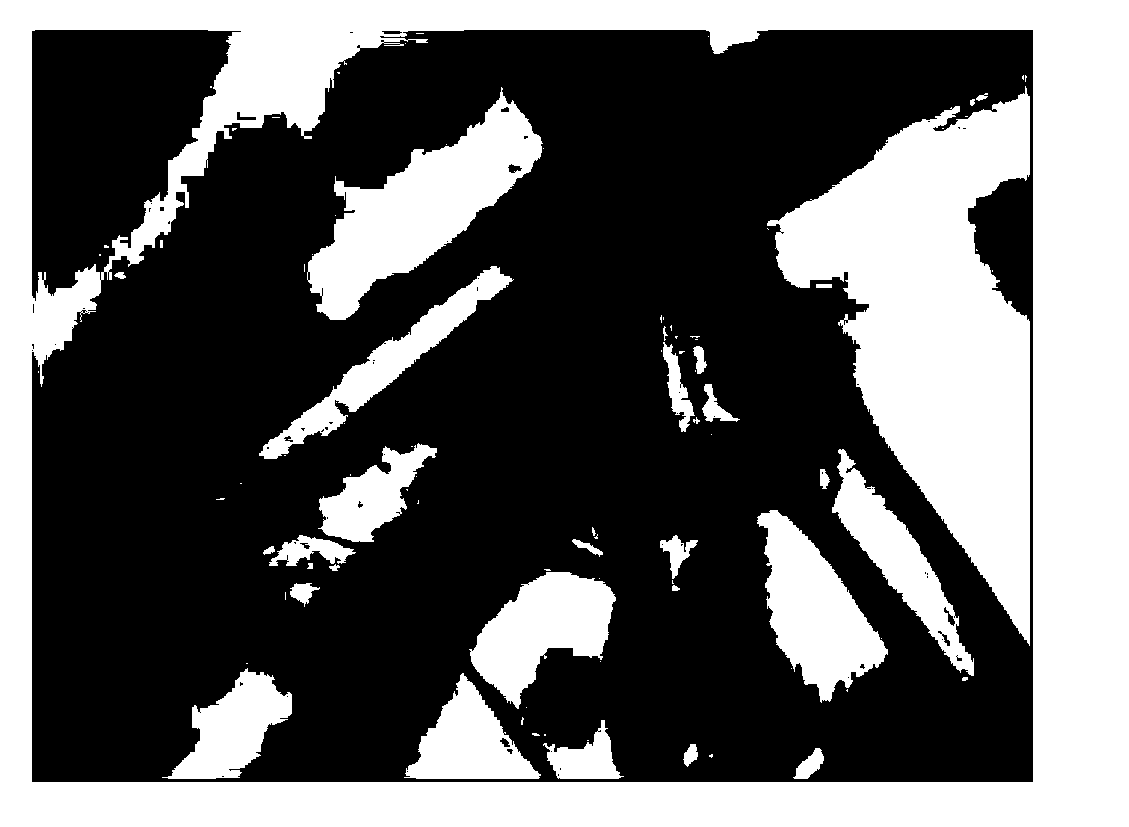

[0102] (Manufacturing example 1) Production of nonwoven fabric covered with aluminum-crosslinked collagen insoluble matter

[0103] 30 g of aqueous hydrogen peroxide solution diluted to 30% by weight was added to 1200 kg of leather pieces (collagen content: 180 kg) obtained by solubilizing with alkali using cow split hide as a raw material, and then dissolved in aqueous lactic acid solution to prepare pH 3.5, solid content 7.5% stock solution. Under reduced pressure, the stock solution was subjected to stirring and defoaming treatment using a stirring defoaming machine (manufactured by Dalton Co., Ltd., 8DMV type), moved to a piston type spinning stock solution tank, and then left to stand under reduced pressure for defoaming, as the following Collagen solution for nonwoven treatment.

[0104]Synthetic fiber non-woven fabric AL035J11-GN-H (manufactured by Jinxing Paper Co., Ltd., with a mass per unit area of 35 g / m) of 5 cm × 12 cm 2 ) was immersed in 300 ml of collagen aq...

manufacture example 2)

[0106] (Manufacture example 2) Production of nonwoven fabric covered with aluminum-crosslinked collagen insoluble matter

[0107] In addition to the pulp mixed fiber nonwoven fabric AL040TCEP-WE (manufactured by Jinxing Paper Co., Ltd., with a mass per unit area of 40 g / m 2 ) except that the collagen concentration in Production Example 1 was adjusted to 0.06% and 0.12% of the aqueous collagen solution, a nonwoven fabric covered with collagen insolubles was obtained in the same manner as in Production Example 1.

[0108] Next, the coverage degree of the collagen of the nonwoven fabric was calculated as the weight increase rate of the nonwoven fabric by immersion in aqueous collagen solution and aluminum crosslinking treatment. As a comparison, an aluminum-crosslinked product of a nonwoven fabric that was not dipped in a collagen aqueous solution was produced, and its weight increase was measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com