Desulfurization and denitrification integral smoke gas purification treatment system and desulfurization and denitrification integral smoke gas purification treatment process

A technology for desulfurization, denitrification, and flue gas purification, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of occupying space, lack of mature technology, consumption of energy materials, etc., to avoid emissions, strong absorption of acidity The ability of oxides and the effect of high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

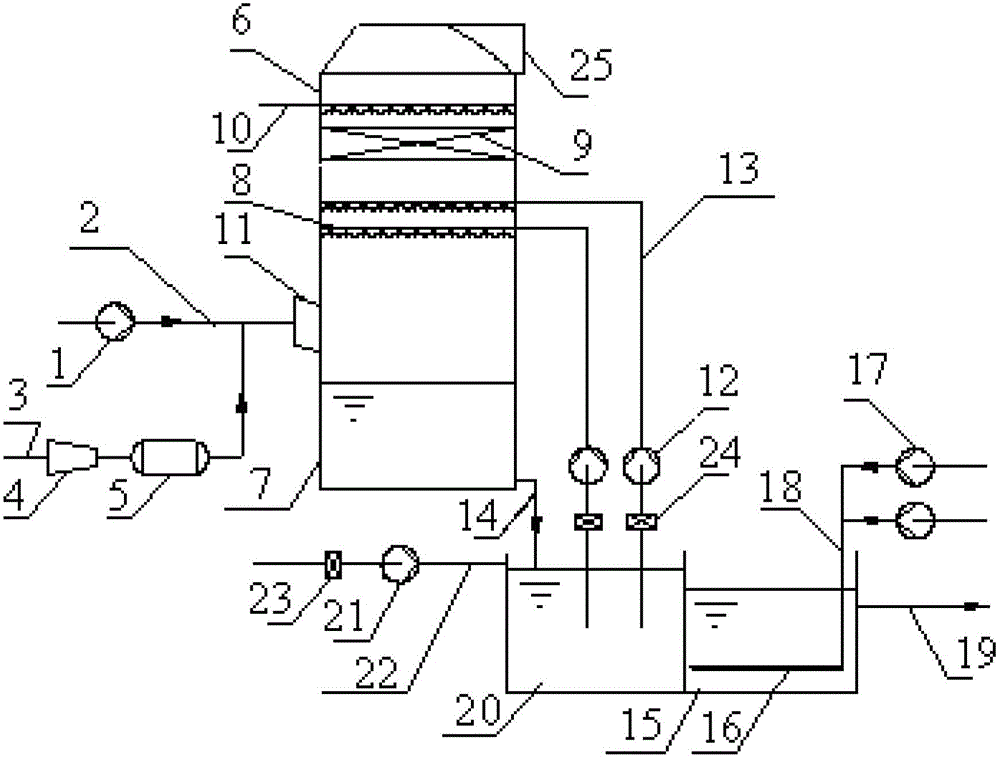

[0031] Such as figure 1 As shown, a desulfurization and denitrification integrated flue gas purification treatment system includes a raw flue gas input system, a raw flue gas oxidation system, an absorption system, a clean flue gas discharge system (not shown in the figure), a comprehensive functional system for desulfurization and denitration agents, Acidity adjustment device, wherein:

[0032] The raw flue gas input system includes a raw flue gas input booster fan 1 and a raw flue gas input pipeline 2 connected to each other;

[0033] The former flue gas oxidation system is an ozone oxidation system, comprising an air input pipeline 3, an air compressor 4 and an ozone generator 5 connected to each other for ozone, and the ozone generator 5 is connected with the former flue gas input pipeline 2;

[0034] The absorption system includes an absorption tower 6, a liquid storage tank 7, a spray device and a demisting device arranged in sequence from bottom to top in the absorptio...

Embodiment 2

[0069] Such as figure 1 As shown, the setting and distribution of a desulfurization and denitrification integrated flue gas purification treatment system are the same as in Embodiment 1.

[0070] Applying the desulfurization and denitrification integrated flue gas purification treatment system of the present invention to carry out flue gas desulfurization and denitrification purification treatment is the same as in Example 1, except for the following steps:

[0071] In step (2), when the pH value of the obtained absorption liquid is 2.5, open the discharge valve, so that the absorption liquid flows into the mixing tank 20 through the absorption liquid discharge pipe 14; the pH value of the mixed liquid in the mixing tank is maintained at 5.4 through the acidity adjustment device; After the liquid is oxidized in the oxidation tank 15 to reach a pH value of 7.5, the oxidized mixed liquid flows into the discharge channel 19 by gravity using the potential difference between the ox...

Embodiment 3

[0074] Such as figure 1 As shown, the setting and distribution of a desulfurization and denitrification integrated flue gas purification treatment system are the same as in Embodiment 1.

[0075] Applying the desulfurization and denitrification integrated flue gas purification treatment system of the present invention to carry out flue gas desulfurization and denitrification purification treatment is the same as in Example 1, except for the following steps:

[0076] In step (2), when the pH value of the obtained absorption liquid is 3.0, open the discharge valve, so that the absorption liquid flows into the mixing pool 20 through the absorption liquid discharge pipe 14; the pH value of the mixed liquid in the mixing pool is maintained at 5.2 through the acidity adjustment device; After the liquid is oxidized in the oxidation tank 15 to reach a pH value of 7.3, the oxidized mixed liquid flows into the discharge channel 19 by gravity using the potential difference between the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com