Composite filler for biologically filtering industrial waste gas

A combination of packing and biological filtration technology, which is applied in the direction of air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of urban ambient air quality hazards, industrial waste gas diffusion, etc., and achieve low cost, uniform gas distribution, and acid The effect of strong alkali buffering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Treatment of waste gas from production workshops in the paint and coatings industry

[0015] The composition ratio of this embodiment is as follows: the bark is blocky and the particle size is less than 50 mm, the compost is granular and the particle size is less than 5 mm, the inorganic medium includes ceramsite, plastic balls and shells, the ceramsite and plastic balls are spherical, and the diameters are respectively Smaller than 25mm and 500mm, the shell is irregular in shape, and the size range is between 10mm and 20mm. The weight ratio of each component is bark: compost: ceramsite: plastic ball: shell=98:53:84:50:100. The shell alkalinity is 440g / kg (calculated as calcium carbonate). The bulk density of the combined packing is 450kg / m 3 , the porosity is 55.5%, and the carbon-nitrogen ratio is 100:5.

[0016] The combined packing is filled in the biofiltration reactor of the prior art, the reactor is 2000 mm high, 1500 mm long, 1500 mm wide, and the ...

Embodiment 2

[0017] Example 2: Treatment of Common Exhaust Gas

[0018] The composition ratio of the present embodiment is: the form requirements of each component are the same as in Example 1, and the weight ratio is bark: compost: ceramsite: plastic ball: shell=104:60:90:56:105. The shell alkalinity is 680g / kg (calculated as calcium carbonate). The bulk density of the combined packing is 450kg / m 3 , the porosity is 55.5%, and the carbon-nitrogen ratio is 100:5.

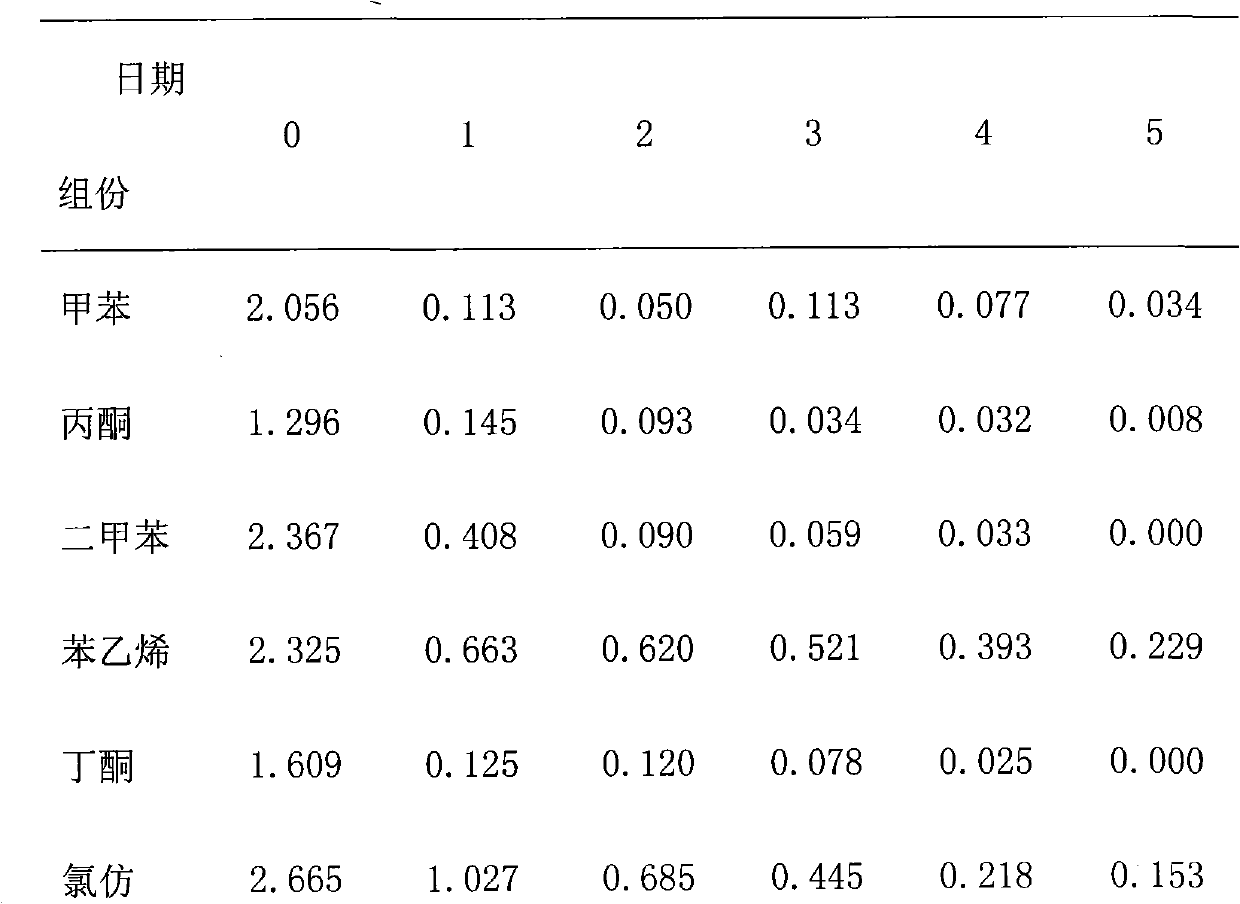

[0019] The combined packing is filled in the biological filtration reaction to treat common industrial waste gas components such as toluene, xylene, styrene, acetone, methyl ethyl ketone, and chloroform. The empty bed residence time of the packed bed is 30s. The processing effect is shown in Table 1:

[0020] Table 1 Purification effect of combined packing biofiltration reactor on different common industrial waste gases (mg / m 3 )

[0021]

[0022] The results show that the combined filler has a strong removal effect on ...

Embodiment 3

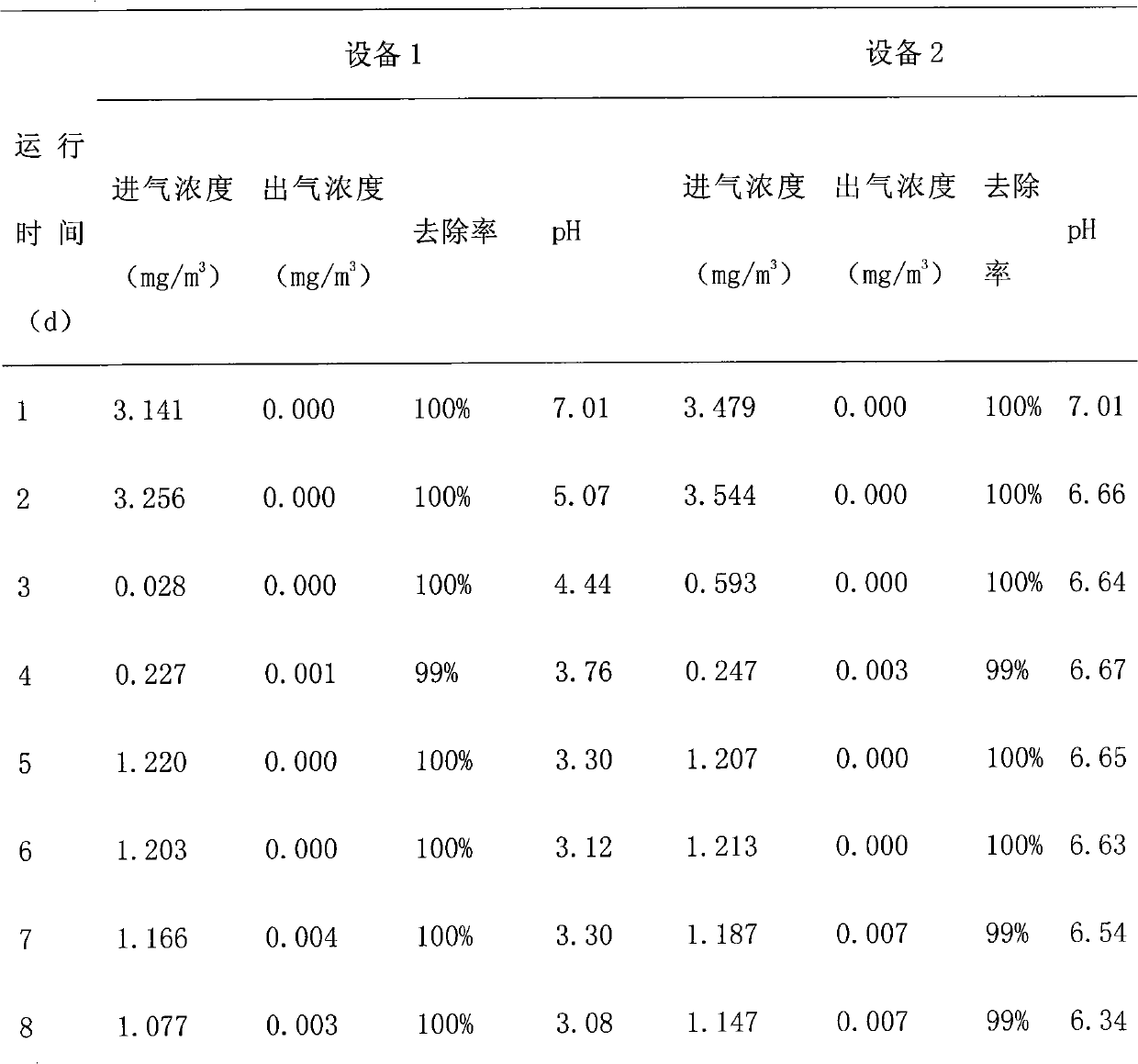

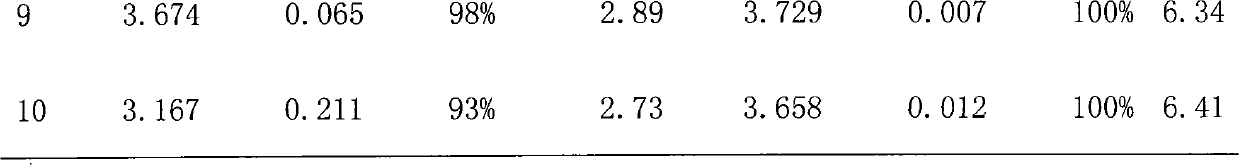

[0023] Embodiment 3: to the processing of sewage plant odor

[0024] Two sets of biological trickling filter devices are running in parallel, specifications: height 2100mm, inner diameter 900mm. The height of the packing layer is 1m, and the packing volume is 0.65m3. Equipment 1 is filled with combined filler of the present invention (the weight ratio of each medium is bark: compost: ceramsite: plastic ball: shell=100: 56: 87: 54: 103. The alkalinity of the shell is 560g / kg in terms of calcium carbonate. All the other requirements are with embodiment 1). Equipment 2 is filled with prior art combined filler (weight ratio is bark: compost: ceramsite=100:48:130). The operating conditions of the two sets of equipment are the same, and the gas residence time is 20s. The processing effect is shown in Table 2:

[0025] Table 2 Treatment effect of combined packing on odor in sewage plant

[0026]

[0027]

[0028] The result shows that the combined packing of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com