Polytetrafluoroethylene microporous film and production method thereof

A polytetrafluoroethylene, manufacturing method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve the problem that polytetrafluoroethylene microporous membrane has large pore size, water resistance and moisture permeability cannot meet the requirements , water pressure resistance or filtration effect can not meet the application requirements and other problems, to achieve the effect of high nanofiber content, improved air permeability, good water washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 (production of polytetrafluoroethylene dispersion resin with core-shell structure)

[0031] In a horizontal autoclave of about 100 liters, first add 50 L of deionized water and 15 g of perfluorooctanoic acid ammonium, vacuumize the oxygen in the autoclave until the oxygen content is 2 . Add 1g of ammonium persulfate (dissolved in 500mL of water in advance) into the kettle as an initiator to start the copolymerization reaction. The temperature in the kettle is maintained at 70~110℃, and the pressure decreases with the reaction, and drops to less than 5kg / cm after about 1 hour 2 . At this time, the core part of the polytetrafluoroethylene dispersed resin primary particle (tetrafluoroethylene copolymer) is polymerized, the solid content of the emulsion is about 6%, and the average particle diameter of the primary particle is about 80nm.

[0032] Then vacuumize the inside of the kettle, and then feed tetrafluoroethylene monomer with a molar concentration>99.999%,...

Embodiment 2

[0033] Example 2 (production of polytetrafluoroethylene dispersion resin with core-shell structure)

[0034] In a horizontal autoclave of about 100 liters, first add 50 L of deionized water and 18 g of perfluorooctanoic acid ammonium, vacuumize the oxygen in the autoclave until the oxygen content is 2 . Add 0.2g of ammonium persulfate (dissolved in 500mL of water in advance) into the kettle as an initiator to start the copolymerization reaction. The temperature in the kettle is maintained at 70~110℃, and the pressure decreases with the reaction, and drops to less than 5kg / cm after about 1 hour 2At this time, the core part of the polytetrafluoroethylene dispersed resin primary particles (tetrafluoroethylene copolymer) is polymerized, the solid content of the emulsion is about 3%, and the average particle size of the primary particles is about 100nm.

[0035] Then vacuumize the inside of the kettle, and then feed tetrafluoroethylene monomer with a molar concentration>99.999%, an...

Embodiment 3

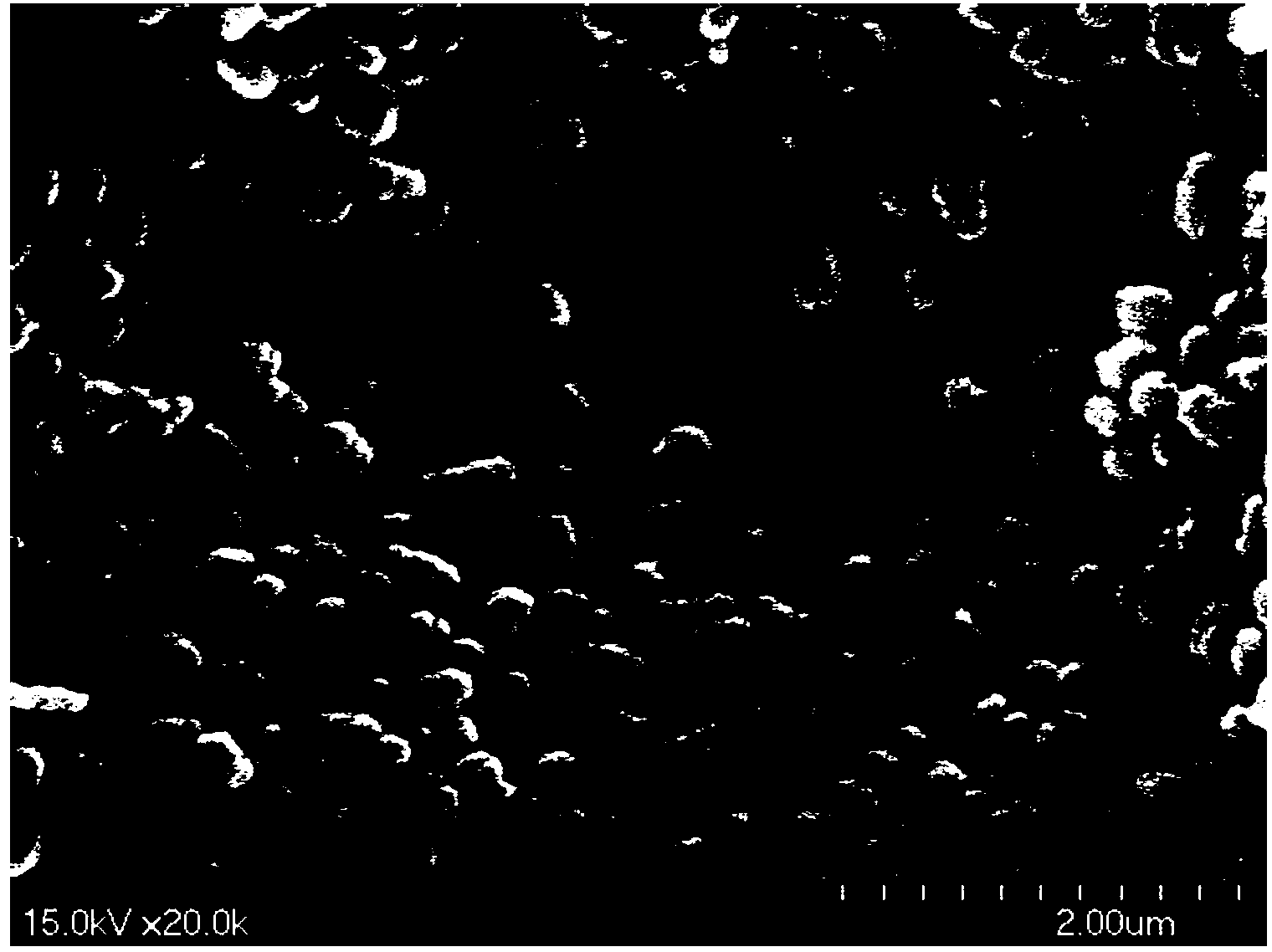

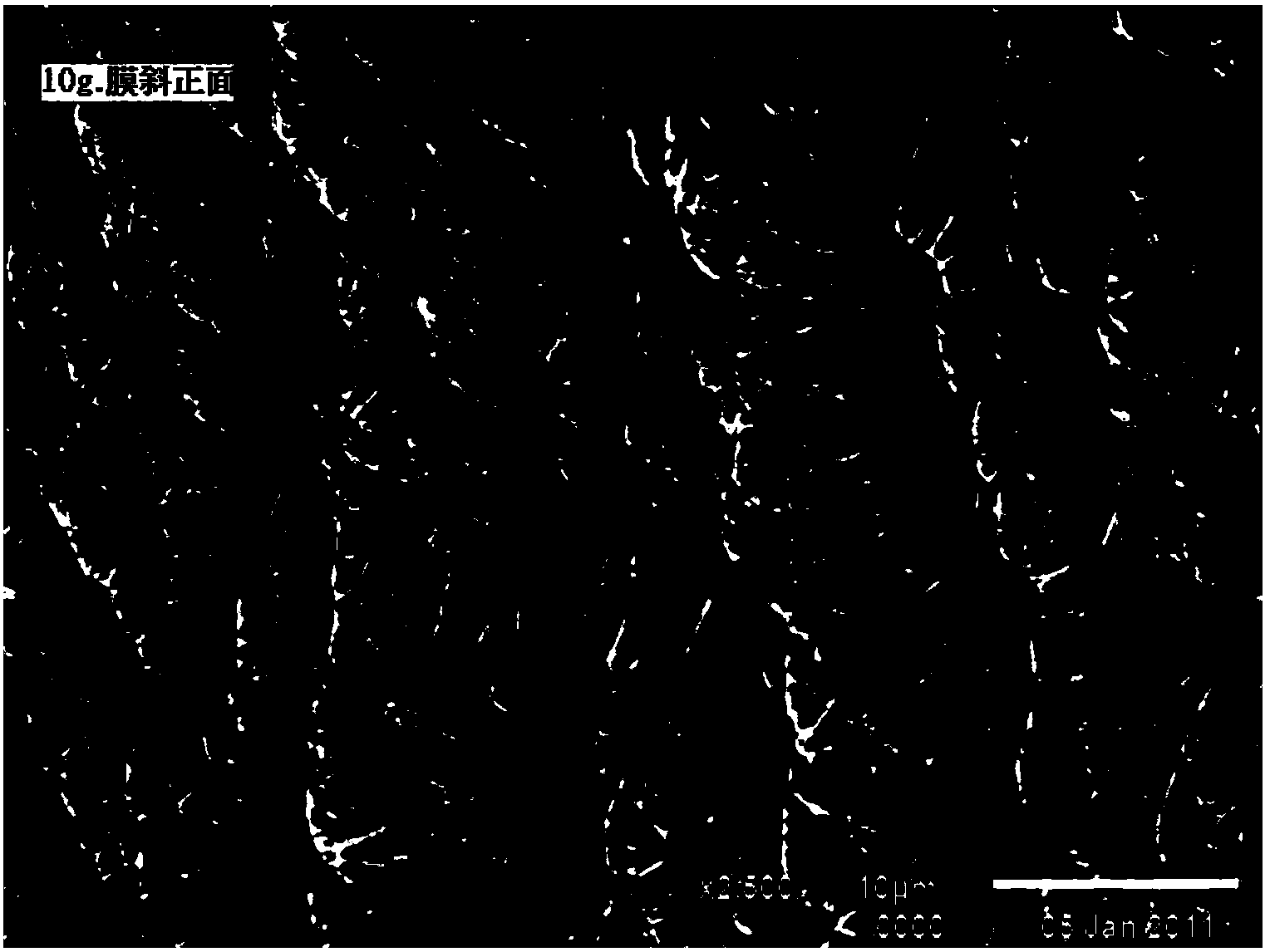

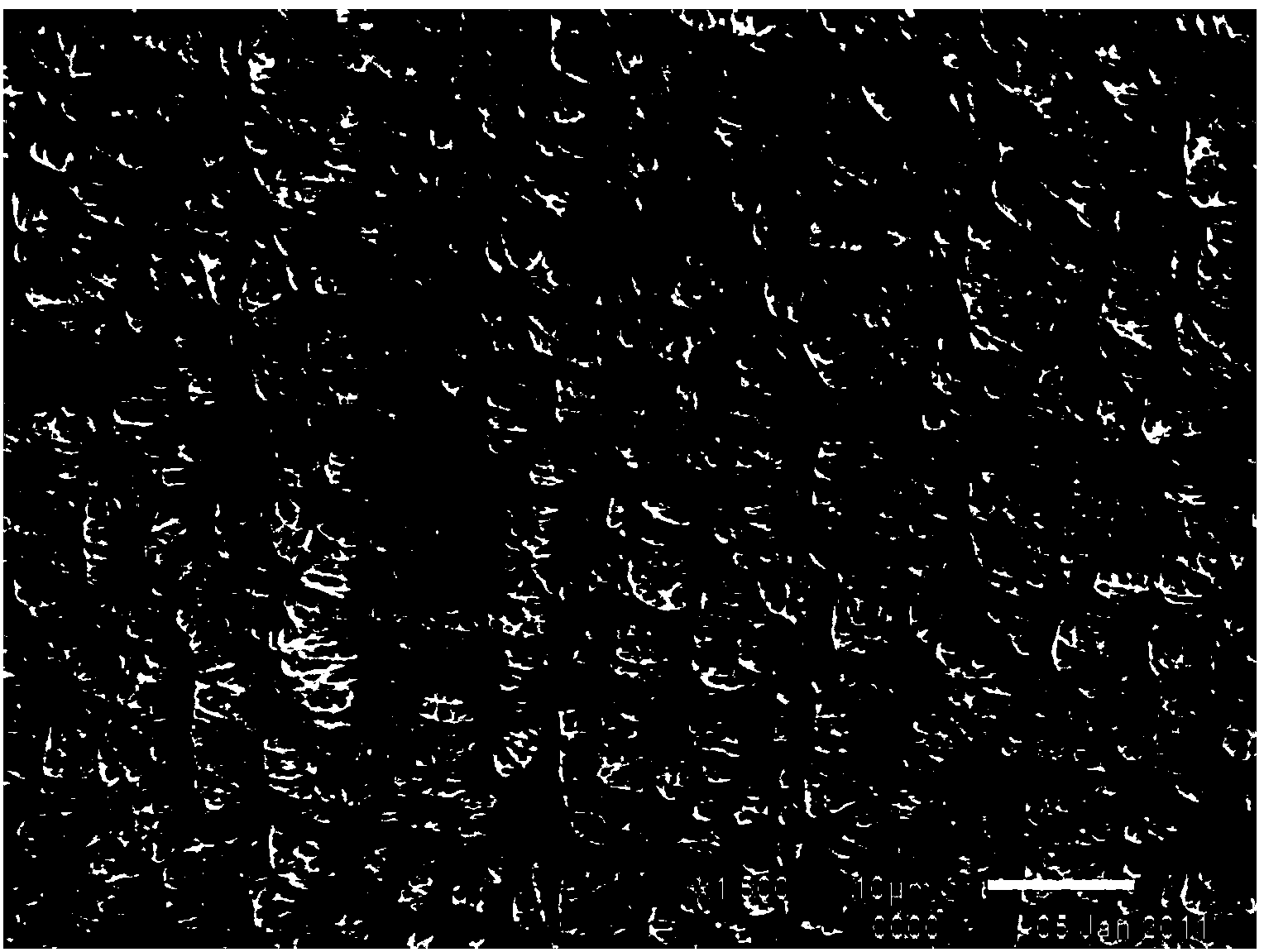

[0036] Embodiment 3 (manufacture of polytetrafluoroethylene microporous membrane)

[0037] Mix the polytetrafluoroethylene dispersion resin with a core-shell structure obtained in Example 1 with the American Exxon Mobil advanced lubricant (brand Isopar M) in a weight ratio of about 5:1, and pre-press it into a cylindrical shape after stirring evenly Then extrude the paste under high pressure at about 50°C, and calender it into strips with a thickness of about 0.1mm. The strip was stretched about 3 times transversely and deoiled in an oven at about 260° C. to obtain a dry film. The dry film is stretched about 10 times longitudinally at a high temperature of about 340°C, then stretched about 10 times transversely at a high temperature of about 360°C, and finally shaped at a high temperature of about 390°C to obtain polytetrafluoroethylene. Vinyl microporous membrane.

[0038] After testing, the average pore diameter of the obtained polytetrafluoroethylene microporous membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com