Preparation method of layered porous carbon particles in yolk-shell structure

A technology of hierarchical porous carbon and core-shell structure, applied in the preparation of microspheres, nanocarbons, microcapsule preparations, etc., can solve problems such as industrialization difficulties and cumbersome processes, and achieve the effect of simple equipment, simple process, and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

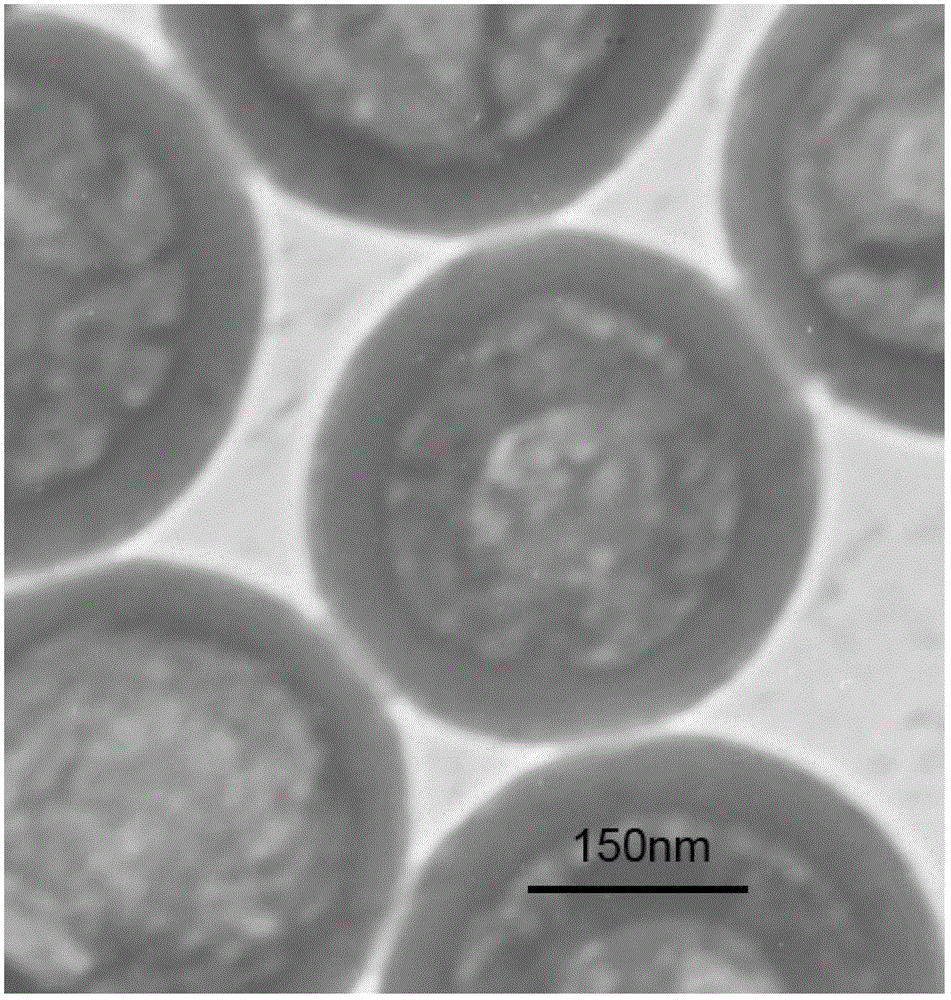

Embodiment 1

[0025] Preparation of egg yolk-eggshell structured carbon micro-nano particles. Weigh 3.88g resorcinol, 5.2ml formaldehyde, mix and stir for 1 hour, add 30ml deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution , Measure 15ml of polystyrene hollow microspheres, stir and mix at room temperature for 24 hours. Wash by centrifugation for 3 times, add 15ml of water and then add acetic acid to stir and mix evenly, leave it at room temperature for 12 hours, and wash by centrifugation to obtain particles with a core-shell structure. Weigh 7.76g resorcinol, 11ml formaldehyde, mix and stir for 1 hour, add 60ml deionized water, add 1ml sodium hydroxide 1mol / L, mix and stir for 5 hours to form a uniform carbon precursor solution , after reacting for 6 hours, centrifuge and wash 3 times to obtain micro-nano particles with core-shell structure, dry them at 60°C, put the powder into a high-temperature atmosphere furnace, and pass argon gas at a rate of 0.1...

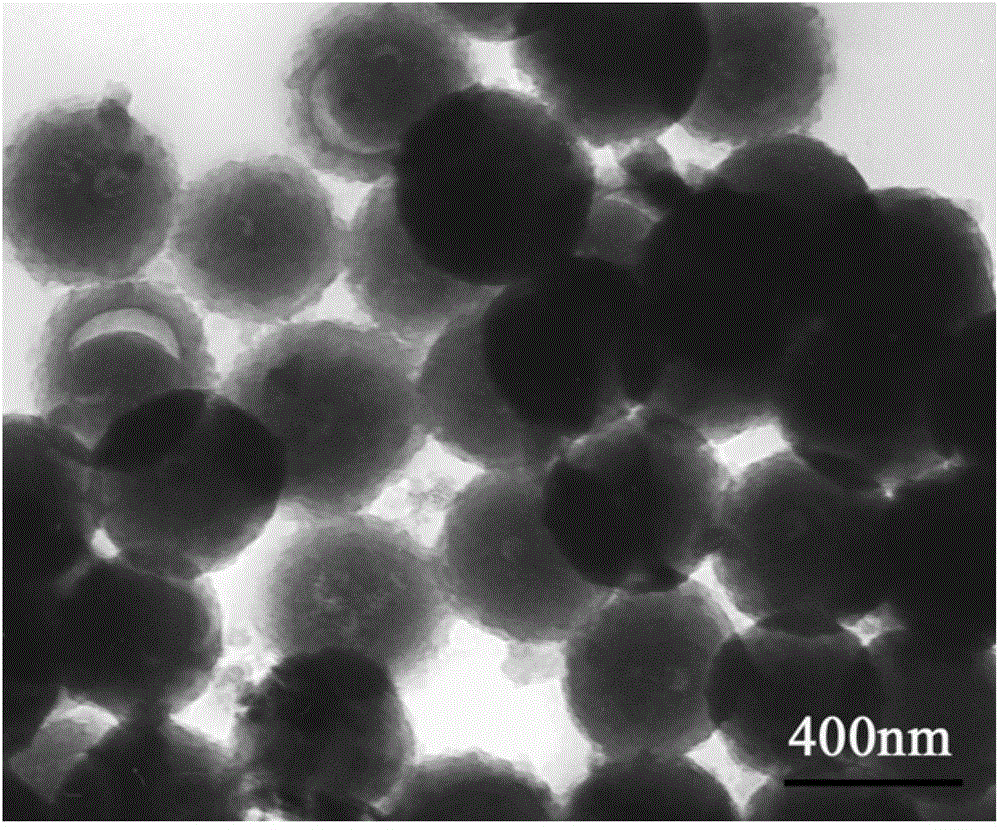

Embodiment 2

[0027] Preparation of egg yolk-eggshell structure micro-nano carbon particles. Weigh 7.76g resorcinol, 11ml formaldehyde, mix and stir for 1 hour, add 30ml deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution , Measure 15ml of polystyrene hollow microspheres, stir and mix at room temperature for 24 hours. Wash by centrifugation for 3 times, add 15ml of water and then add acetic acid to stir and mix evenly, leave it at room temperature for 12 hours, and wash by centrifugation for 2 times to obtain particles with a core-shell structure. Weigh 7.76g resorcinol, 11ml formaldehyde, mix and stir for 1 hour, add 60ml deionized water, add 1ml sodium hydroxide 1mol / L, mix and stir for 5 hours to form a uniform carbon precursor solution , after reacting for 6 hours, centrifuge and wash 3 times to obtain micro-nano particles with core-shell structure, dry them at 60°C, put the powder into a high-temperature atmosphere furnace, and pass argon gas at a r...

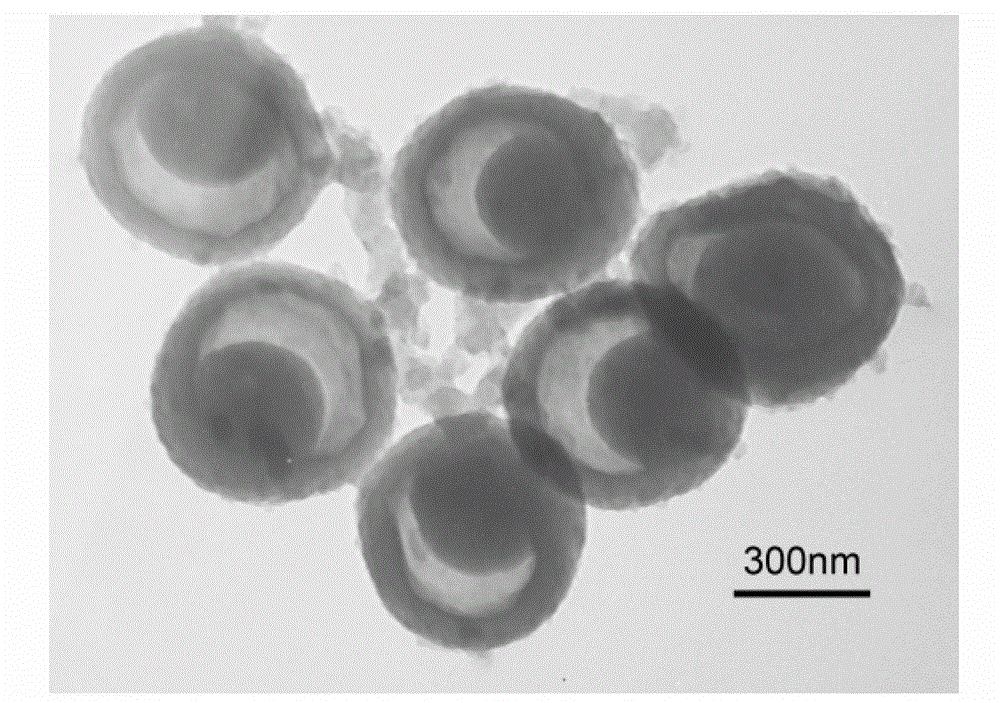

Embodiment 3

[0030] Preparation of egg yolk-eggshell structure micro-nano carbon particles. Weigh 3.88g resorcinol, 5.2ml formaldehyde, mix and stir for 1 hour, add 15ml deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution , Measure 15ml of polystyrene hollow microspheres, stir and mix at room temperature for 24 hours. Wash by centrifugation for 3 times, add 15ml of water and then add sulfuric acid to stir and mix evenly, leave it at room temperature for 12 hours, and wash by centrifugation for 2 times to obtain particles with a core-shell structure. Weigh 7.76g resorcinol, 11ml formaldehyde, mix and stir for 1 hour, add 60ml deionized water, add 1ml sodium hydroxide 1mol / L, mix and stir for 5 hours to form a uniform carbon precursor solution , drop the mixed solution containing the core-shell particles in the carbon precursor solution , after reacting for 6 hours, centrifuge and wash 3 times to obtain micro-nano particles with core-shell structure, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com