Method for realizing methanogenesis with surplus sludge by utilizing microbial electrolytic tank

A technology of microbial electrolysis cell and excess sludge, which is applied in biological sludge treatment, waste fuel and other directions, can solve the problems of inability to fully utilize excess sludge and long time, and achieve the effect of short reaction time and reduction of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

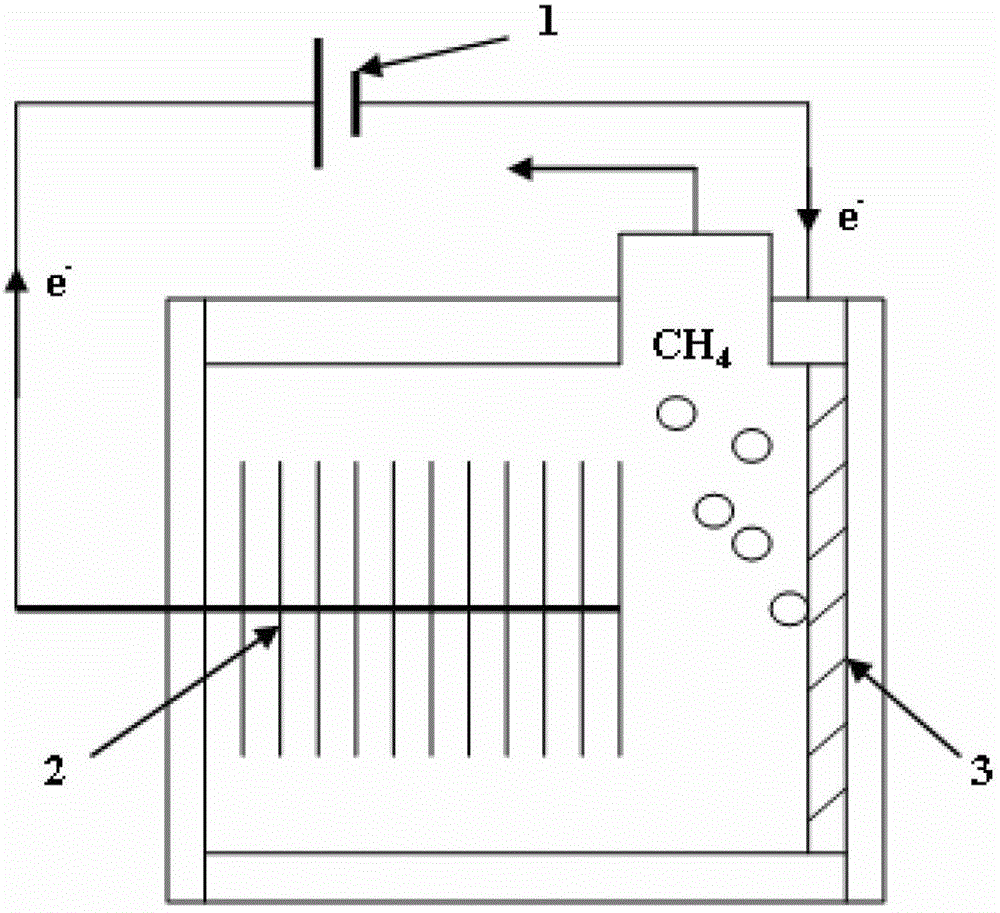

Image

Examples

specific Embodiment approach 1

[0017] Embodiment 1: In this embodiment, the method for utilizing microbial electrolytic cells to realize methane production from excess sludge is realized in the following steps:

[0018] 1. Use excess sludge as a substrate to domesticate anode functional microorganisms and start the microbial electrolytic cell reactor: use a DC power supply as a power source to apply a voltage of 0.4 to 0.8V at both ends of the electrolytic cell, and mix the excess sludge with nutrient solution A to obtain The mixed solution B with a concentration of 9-24g / L is then added to the electrolytic cell, and the new mixed solution B is replaced under the condition that the voltage across the resistance of the closed circuit is lower than half of the initial voltage, and the new mixed solution B is continuously replaced. The anode functional microorganisms are domesticated and enriched until the resistance voltage is continuously stable, and the microbial electrolytic cell reactor can be started;

...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, a DC power supply is used as the power source to apply a voltage of 0.6V to both ends of the electrolytic cell. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, a voltage of 0.6 V is applied to both ends of the electrolytic cell by using a DC power supply as the power source. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com