Method for preparing sodium tauroursodeoxycholate

A technology of sodium tauroursodeoxycholate and tauroursodeoxycholic acid, which is applied in the field of medicine, can solve the problems of difficult separation and purification and low cost, and achieve the effects of simple process, low cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

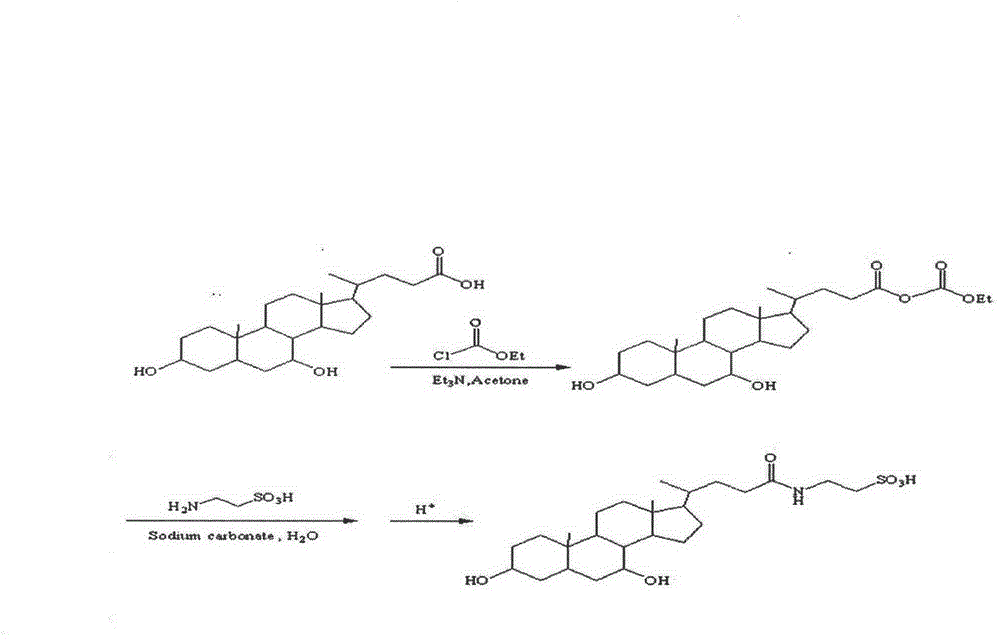

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of sodium tauroursodeoxycholate, comprising:

[0032] (1) 10g of ursodeoxycholic acid raw material (25.5mmol), 2.7g of triethylamine (26.5mmol) dissolved in 100ml of acetone solution, cooled to -5~-10°C, and 2.9g of ethyl chloroformate was added dropwise to the solution Esters (25.97mmol), continue to stir at -5~-10°C for 20min after the dropwise addition, remove the triethylamine salt by filtration, and use the filtrate for later use;

[0033] (2) Condensation reaction of taurine

[0034] Dissolve 4g (31.875mmol) of taurine in 22ml of 1mol / L sodium carbonate solution, add dropwise to the mixed acid anhydride solution obtained in the previous item, add it at a uniform speed within 30min at 20-30°C, stir rapidly for 3h-4h, Filter out the precipitate, and the filtrate is for subsequent use;

[0035] (3) Acid adjustment and concentrated drying

[0036] The above-mentioned filtrate is adjusted to pH 6-7 with 2mol / L HCL solution, the solution is recov...

Embodiment 2

[0043] The large-scale production process of sodium tauroursodeoxycholate of the present invention will be further described below by taking the scale-up production of pilot scale as an example.

[0044](1) Dry the 150L reaction kettle, put in 90L of anhydrous acetone, put in 10kg of ursodeoxycholic acid under stirring and wait for the dispersion to be uniform, the refrigeration pump is preset at -20°C for cold circulation until the temperature in the kettle drops to At -5°C, dilute 2.7kg of triethylamine with 2L of acetone, then add dropwise with a constant pressure funnel, drop it at a constant speed within 20 minutes, keep the temperature in the kettle at -5°C ~ -10°C, rinse with 2L of acetone at constant pressure Funnel, take 2.9kg of ethyl chloroformate diluted with 2-3L of acetone, add it to the constant pressure funnel, drop it into the reaction kettle within 1h, keep the temperature at -3℃~-5℃ for 20min, release the reaction solution and filter to remove the amine Prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com