Poly p-hydroxystyrene based chemically amplified one-component photoresist material, and synthetic method and application thereof

A technology of hydroxystyrene and hydroxyl, which is applied in the field of polymer photosensitive imaging materials, can solve the problems of inconsistent acid distribution, limited compatibility, affecting resolution and line edge roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

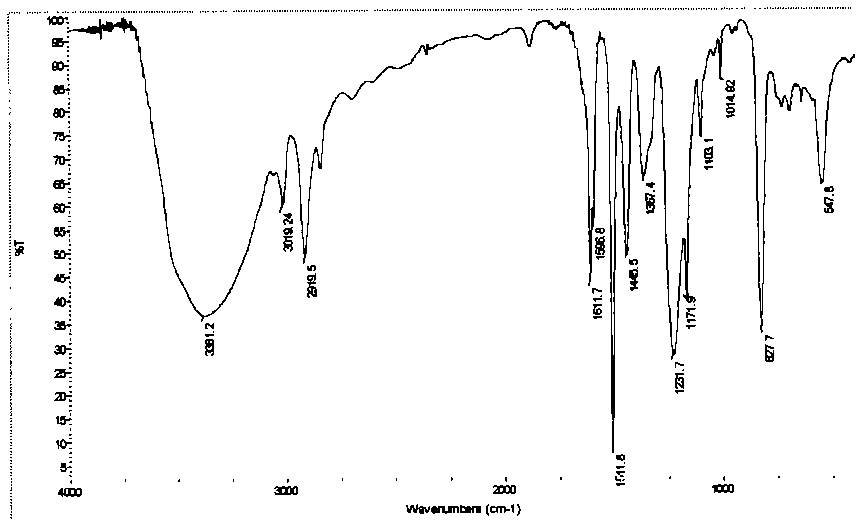

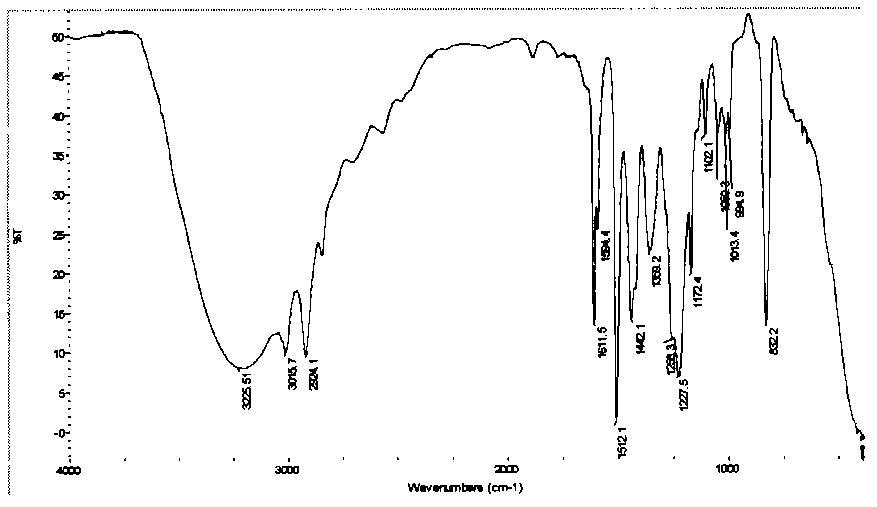

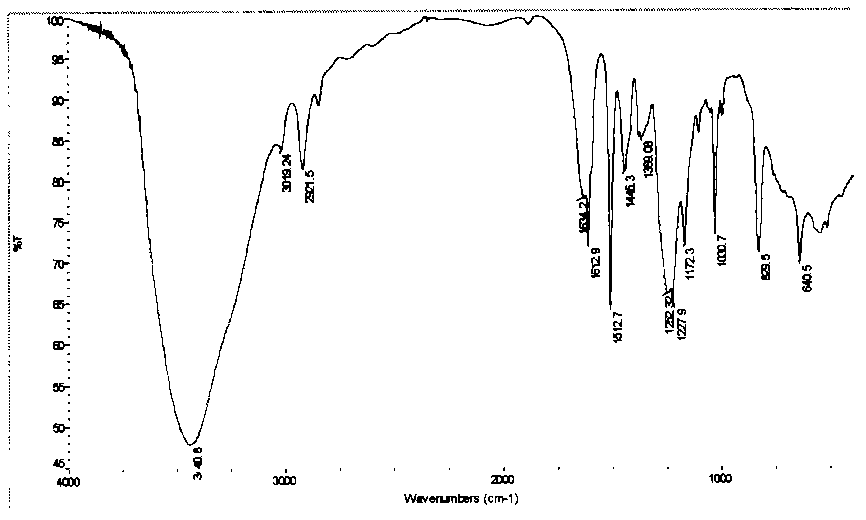

Image

Examples

Embodiment Construction

[0020] Polyparahydroxystyrene (PHS) is the main deep ultraviolet (248nm) photoresist film-forming resin material, there are industrial products in foreign markets (such as Japan), and domestic enterprises are also trying to produce, used in the present invention PHS is repackaged for import. The number average molecular weight of poly-p-hydroxystyrene industrial products is generally in the range of 2000-20000, and its degree of polymerization n is generally in the range of 16-160. Hydrogen chloride is produced by concentrated sulfuric acid and sodium chloride under heating conditions and passed into the reaction system through a buffer bottle. Sodium or potassium salts of strong acids used include sodium triflate, sodium p-toluenesulfonate, sodium benzenesulfonate, potassium nonafluorobutanesulfonate, potassium perfluorooctanesulfonate. Trifluoromethanesulfonic acid has the strongest acidity and is most beneficial to the decomposition reaction of the catalytic protection gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com