Method for building gene engineering strains of producing tryptophan

The technology of a genetically engineered strain and a construction method is applied in the construction field of tryptophan-producing genetically engineered strains, and can solve the problems of high cost, low tryptophan yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

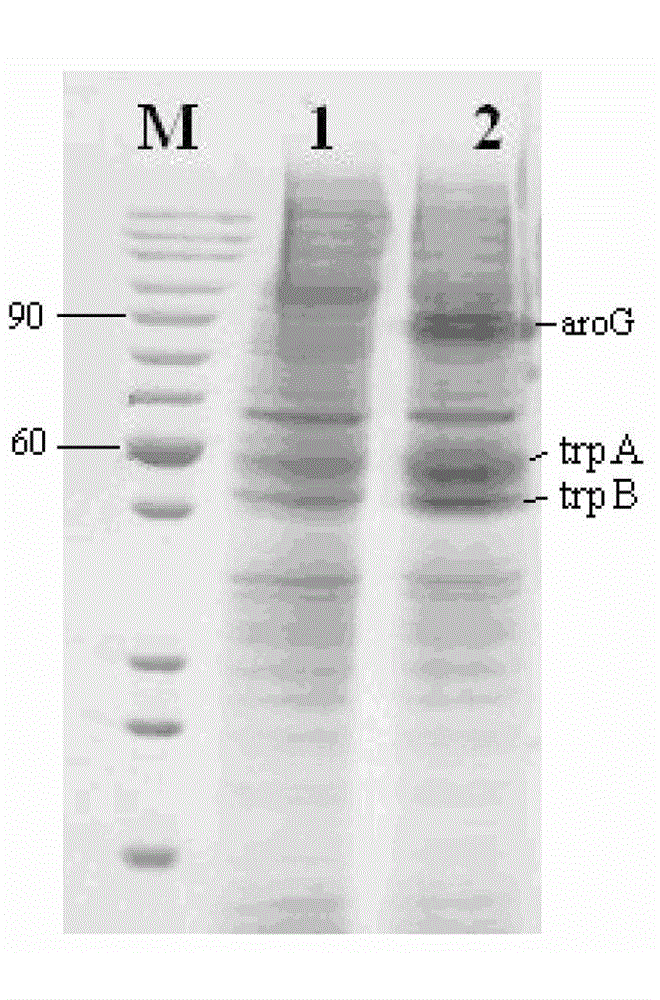

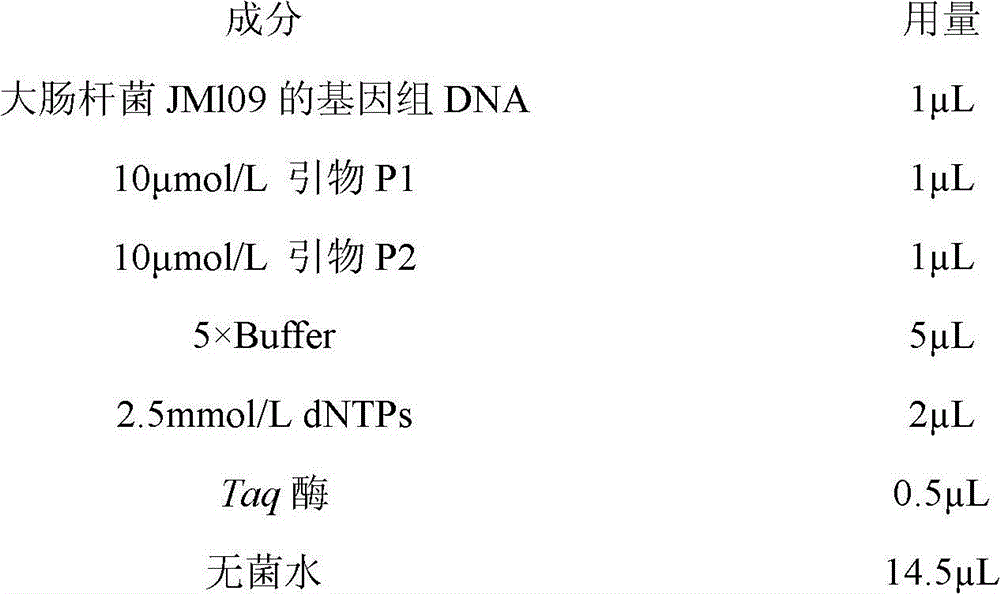

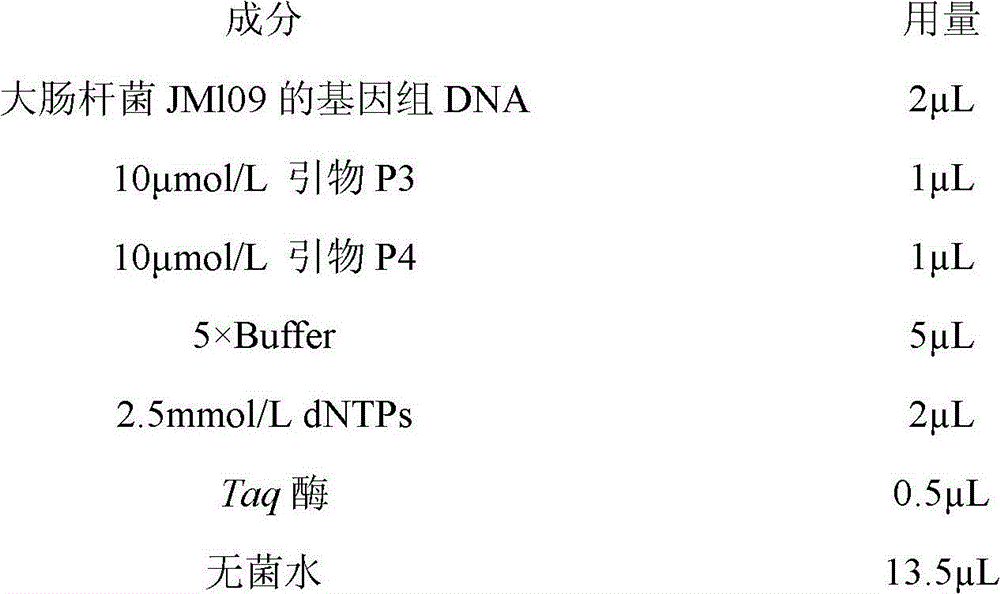

[0012] Specific embodiment one: the construction method of the tryptophan-producing genetically engineered strain of the present embodiment is carried out according to the following steps:

[0013] One, extract the genomic DNA of Escherichia coli JM109 with the bacterial genome extraction kit; Two, use Escherichia coli JM109 genomic DNA as template, carry out PCR amplification with P1, P2 as primer, use 1% agarose coagulation with PCR amplification product A Gel electrophoresis detection, and then use the gel recovery kit to purify to obtain the target gene aroG; 3. Connect the target gene aroG to the pMD18-T vector to construct the recombinant vector pMD18-T-aroG; 4. Use Escherichia coli JM109 genomic DNA as the Template, using P3 and P4 as primers for PCR amplification, PCR amplification product B is detected by 1% agarose gel electrophoresis, and then purified by using a gel recovery kit to obtain the target gene trpBA; 5. Combine the target gene trpBA with The pMD18-T vect...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the primer P1 used in the PCR amplification in step 2 is 5′-CGGAATTCCATCTCTCTCTAGA-3′, and the primer P2 is 5′-CGGGATCCACGTCATTCGTTT-3′. Others are the same as in the first embodiment.

[0022] Primers were designed according to the aroG gene sequence published by NCBI, and appropriate restriction sites EcoRI, BamH I and protective bases were added at both ends.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the primer P3 used for PCR amplification in step 4 is 5′-CGGAATTCTTTTCTTACCCCGGT-3′, and the primer P4 is 5′-CGGGATCCCGCTTGGCAACGTT-3′. Others are the same as in the first or second embodiment.

[0024] Primers were designed according to the trpBA gene sequence published by NCBI, and appropriate restriction sites EcoRI, BamH I and protective bases were added at both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com