Method for depositing and preparing super-hydrophobic indium antimonide thin film from ionic liquid

A technology of superhydrophobicity and ionic liquid is applied in the field of deposition and preparation of superhydrophobic indium antimonide thin films from ionic liquids, which can solve the problems of demand, harsh deposition conditions, strict preparation conditions, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

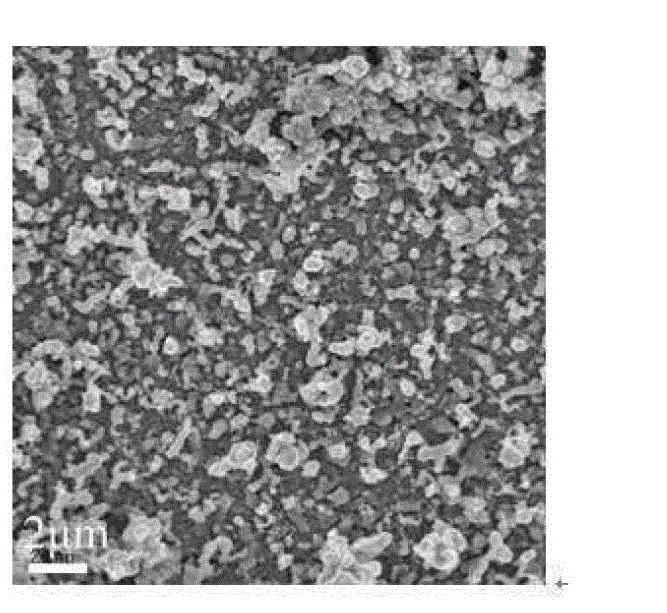

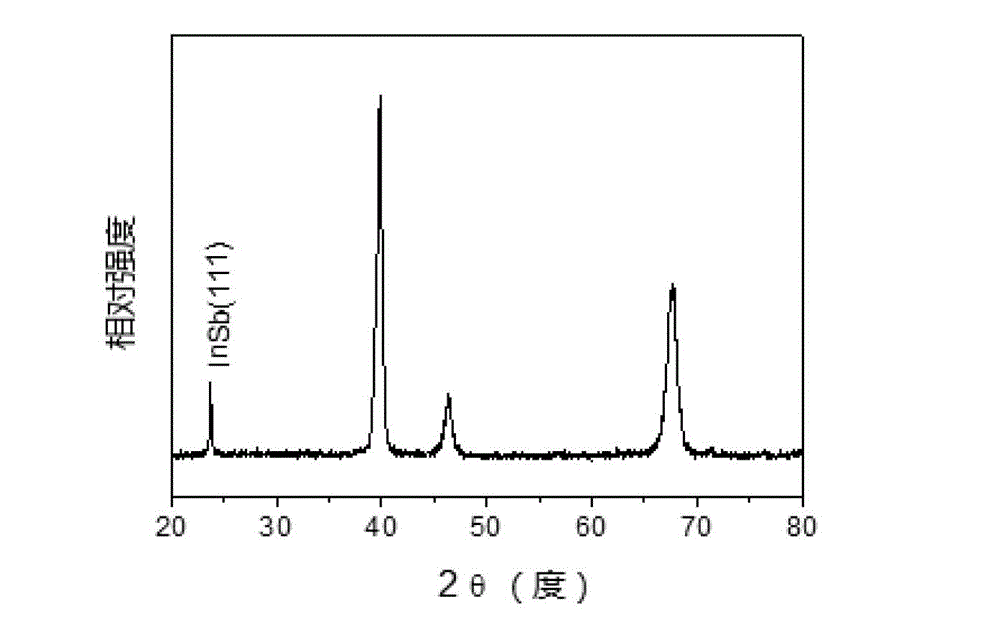

[0021] ① Electrochemical deposition:

[0022] Weigh 0.1383 grams of anhydrous indium chloride and 0.1427 grams of anhydrous antimony chloride, dissolve in 25 milliliters of ionic liquid 1-methyl-3-ethylimidazole bistrifluoromethylsulfonylimide salt, and prepare a concentration of 25mM solution.

[0023] Put the platinum-coated glass substrate into acetone for ultrasonic cleaning, take it out and dry it for use.

[0024] Immerse the cleaned substrate in the above-mentioned ionic liquid solution, use a silver electrode as a reference electrode, and a platinum electrode as an auxiliary electrode, perform electrochemical deposition at a voltage of -1.25V, take it out after 20 hours, and clean it with acetone and deionized water. After drying, a deposited film was obtained.

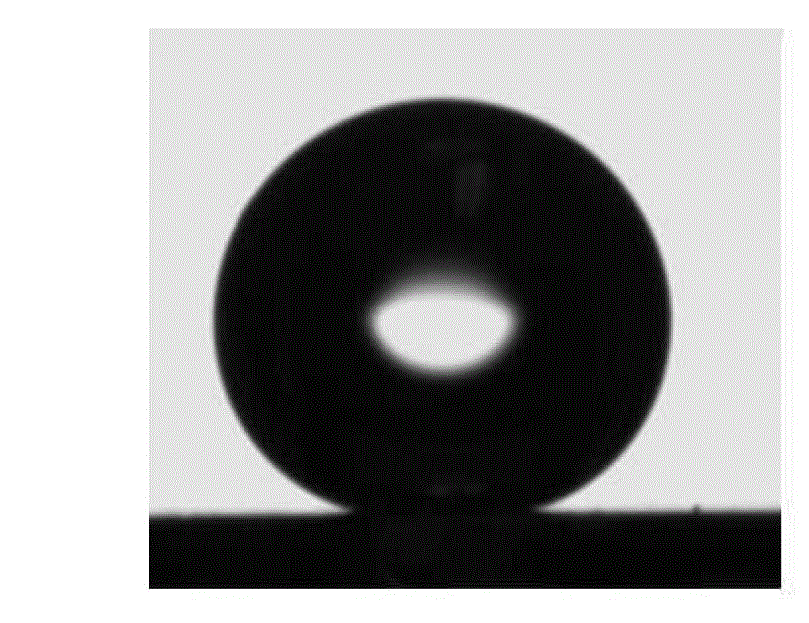

[0025] ② Chemical modification of film surface:

[0026] The deposited film was immersed in an ethanol solution of 1-decyl phosphoric acid with a concentration of 10 mM, kept for 2 hours, taken out, washed ...

Embodiment 2

[0031] ① Electrochemical deposition:

[0032] Weigh 0.0553 gram of anhydrous indium chloride and 0.0571 gram of anhydrous antimony chloride, dissolve them in 25 milliliters of ionic liquid 1-methyl-3-ethylimidazole bistrifluoromethylsulfonylimide salt, and prepare a concentration of 10mM solution.

[0033] The conductive glass substrate was ultrasonically cleaned in acetone and then taken out to dry for use.

[0034] Immerse the cleaned substrate in the above-mentioned ionic liquid solution, use the silver electrode as the reference electrode, and the platinum electrode as the auxiliary electrode, carry out electrochemical deposition at a voltage of -1.35V, take it out after 6 hours, and wash it with acetone and deionized water. After drying, a deposited film was obtained.

[0035] ② Chemical modification of film surface:

[0036] The deposited film was immersed in an ethanol solution of 1-tetradecylphosphoric acid with a concentration of 10 mM, kept for 2 hours, taken out,...

Embodiment 3

[0038] ① Electrochemical deposition:

[0039] Weigh 0.2766 grams of anhydrous indium chloride and 0.2854 grams of anhydrous antimony chloride, dissolve them in 25 milliliters of ionic liquid 1-methyl-3-ethylimidazole bistrifluoromethylsulfonylimide salt, and prepare a concentration of 50mM solution.

[0040] The copper substrate was ultrasonically cleaned in acetone and then taken out to dry for use.

[0041] The cleaned substrate was immersed in the above-mentioned ionic liquid solution, with a silver electrode as a reference electrode and a platinum electrode as an auxiliary electrode, and electrochemical deposition was carried out at a voltage of -1.45V. After 4 hours, it was taken out and cleaned with acetone and deionized water. After drying, a deposited film was obtained.

[0042] ② Chemical modification of film surface:

[0043] The deposited film was immersed in a n-hexane solution of perfluorooctyltrichlorosilane with a concentration of 2mM, kept for 2 hours, taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com