Method for modified atmosphere processing of beef

A processing method and beef technology, which are applied to the processing field of ready-to-eat products, can solve the problems of short shelf life of food, irregular beef pieces, and poor taste, so as to overcome the irregular shape of beef pieces, have a good protective effect, and prolong the freshness preservation. period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Choose fresh beef bonzi meat, wash it after removing impurities, and cut it into 2~4×2~4cm beef sections;

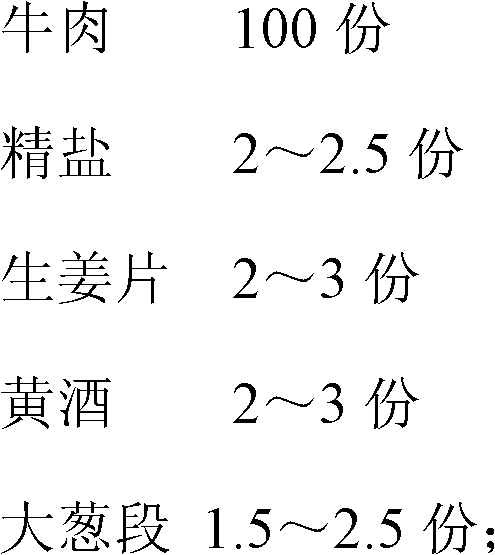

[0030] (2) Marinate: the beef in step (1) is placed in the following raw materials in parts by weight, and marinated for 1 hour:

[0031]

[0032] (3) The product of step (2) is placed in a jacketed pot with a water temperature of 100° C., and pre-cooked for 13 minutes until the beef is firm and brown, and the dehydration rate reaches 52%;

[0033] (4) Braised: Put the product of step (3) together with spice water and seasoning into a pot and boil for 30 minutes, pick up and cool and then slice.

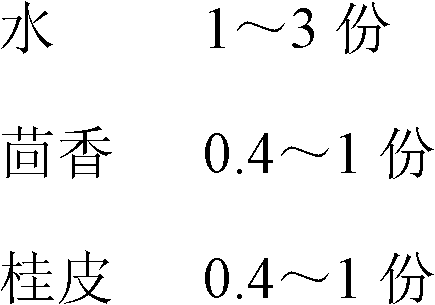

[0034] The flavored water is obtained by boiling the following components in parts by weight at 85°C for 60 minutes:

[0035]

[0036]

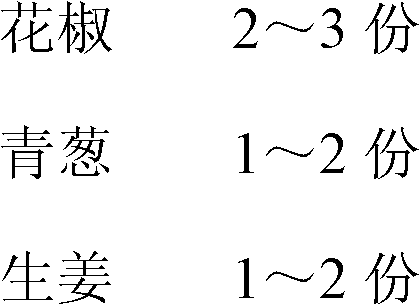

[0037] The seasoning consists of the following components in parts by weight:

[0038]

[0039] The weight ratio of the product of step (3) and spice water is:=1:1

[0040] The product of step (3): seasoning = 1: ~ 1....

Embodiment 2

[0046] (1) Select the frozen beef meat. After the frozen meat is naturally thawed and impurities are removed, please wash it and cut it into 2~4×2~4cm beef sections;

[0047] (2) Marinate: the beef in step (1) is placed in the following raw materials in parts by weight, and marinated for 2 hours:

[0048]

[0049] (3) Precooking: put the pickled product of step (2) in a sandwich pot with a water temperature of 200°C, and precook for 15 minutes until the beef is firm and brown, and the dehydration rate reaches 62%;

[0050] (4) Braised: Put the precooked product of step (3) into a pot together with spice water and seasonings and boil for 40 minutes. Pick up and cool and slice.

[0051] The flavored water is obtained by boiling the following components by weight at 100°C for 50 minutes;

[0052]

[0053] The seasoning consists of the following components in parts by weight:

[0054]

[0055]

[0056] The weight ratio of the product of step (3) and flavor water is:=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com