Oxygen supply system special for oxygen-rich fermentation of sludge

An oxygen supply system and oxygen-enriched technology, applied in biological sludge treatment, oxygen preparation, waste fuel, etc., can solve the problems of reduced reaction speed, high energy consumption operating costs, and reduced fermentation temperature, reducing gas flow and ensuring oxygen Supply, effect of increased oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

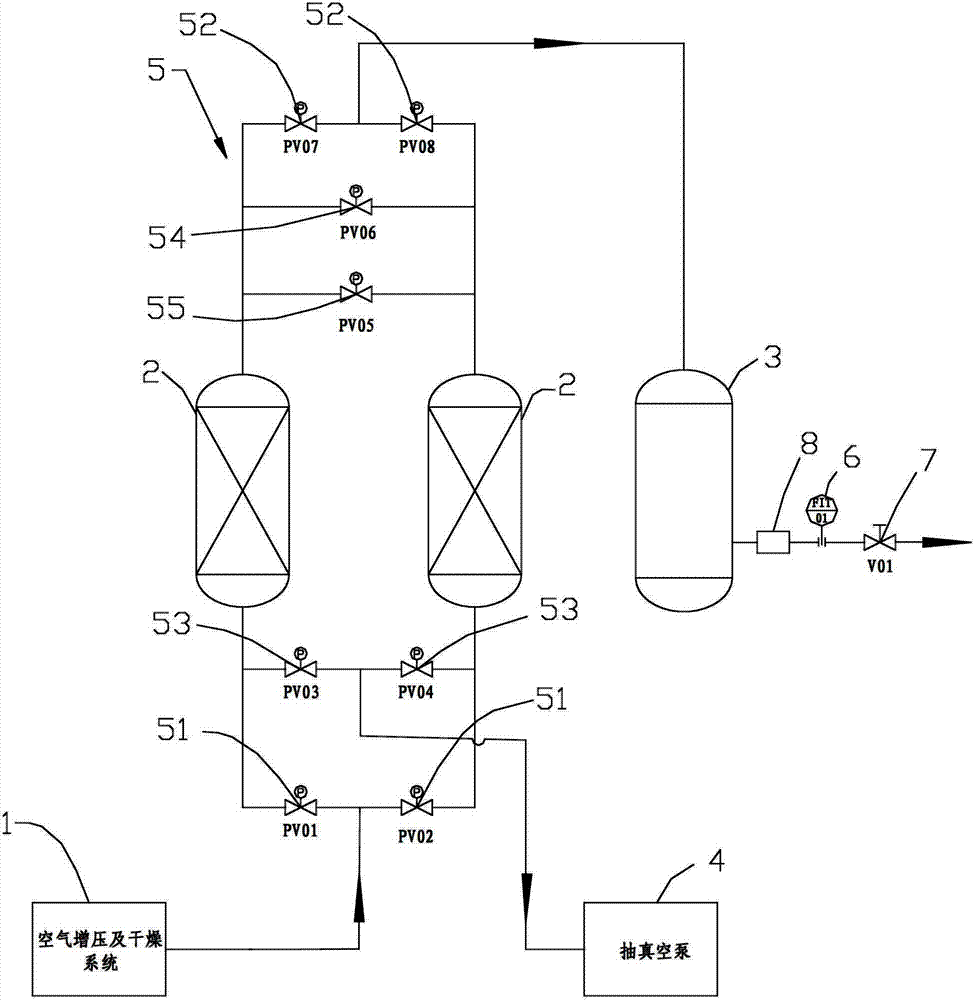

[0016] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

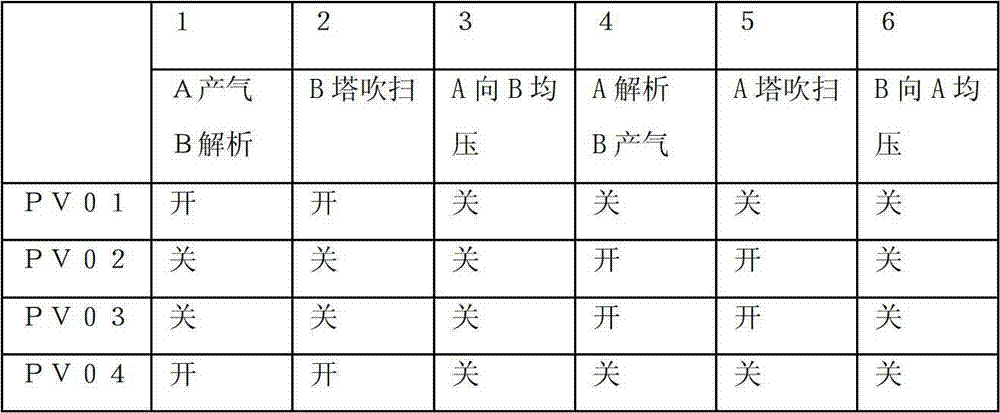

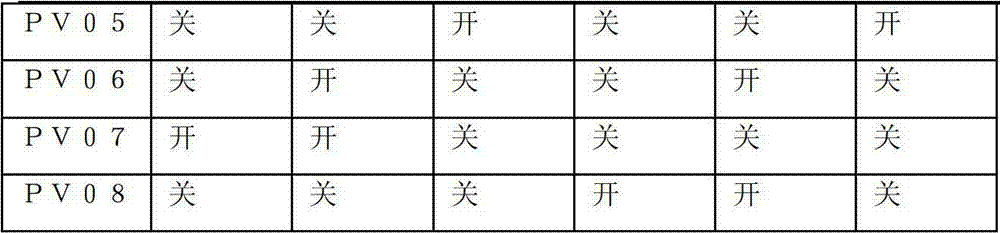

[0017] see figure 1 , a special oxygen supply system for sludge oxygen-enriched fermentation, including air pressurization and drying system 1, two adsorption towers 2, automatic switching valve group 5, oxygen buffer tank 3, vacuum pump 4, air pressurization and drying system 1 The surrounding air is pressurized, and the air is cooled and dehydrated by means of refrigerant, cooling water heat exchange and other means. The air pressurization and drying system 1 can also be equipped with a filter to remove dust particles and oil gas and other impurities in the air. . In each of the two adsorption towers 2, an air distributor, a filler, an oxygen-generating molecular sieve, and a compacting mechanism are placed in sequence from bottom to top. The air distributor can evenly distribute the input air, and the evenly distributed air is then Through the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com