Dry-separation enrichment separation method and system applied to same

A separation method and enrichment technology, applied in the field of gravity separation, to achieve the effect of cost saving and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Primary screening of ore

[0039] The iron ore is crushed with a crusher, after dry grinding, the material is firstly separated by a friction vibration separator, and under the condition of vibrating by the first vibrator in one direction, the coarse separation of particle size classification is carried out by point blanking, and the 0.45-0.06 MM iron ore particles are divided into 0.1-0.06MM iron ore, 0.25-0.1MM iron ore and 0.45-0.2MM iron ore according to particle size. The vibration frequency of the first vibrator is 21HZ and the amplitude is 6mm .

[0040] 2. Enrichment of ore after rough separation

[0041]The three groups of iron ores separated above are transported to the dry separation and enrichment machine described in Example 1, and enriched by line blanking under the conditions of different airflows and the vibration of the second vibrator in one direction. , the vibration frequency of the second vibrator is 30HZ, and the amplitude is 0.3-3mm; the por...

Embodiment 2

[0045] The ilmenite, which is located in Dali, Yunnan, contains 60 mesh ilmenite with a content of 18%, and the ore particles below 0.1MM account for less than 1% of the ore content. Therefore, a simplified process is adopted, and only sand making machines are used. After peeling off the soil, directly enter the enrichment machine, directly use the dry separation enrichment machine described in Example 2, under the condition of passing through the air flow and the vibration of the second vibrator in one direction, enrich by line blanking, the resulting The vibration frequency of the second vibrator is 30HZ, and the amplitude is 0.3-3mm; the porous plate is provided with evenly distributed micropores, the distance between the micropores is <100 μm, and the diameter of the micropores is <30 μm.

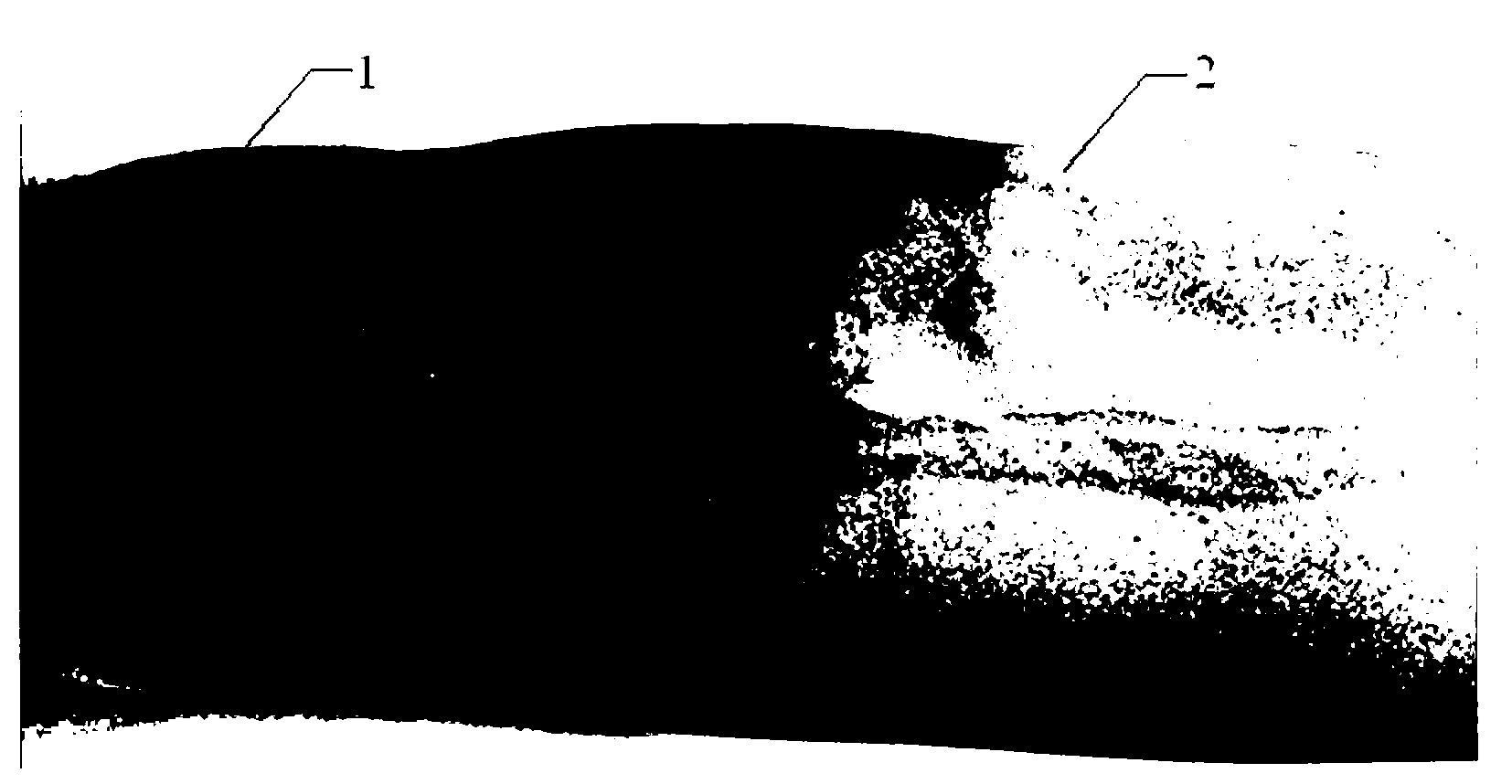

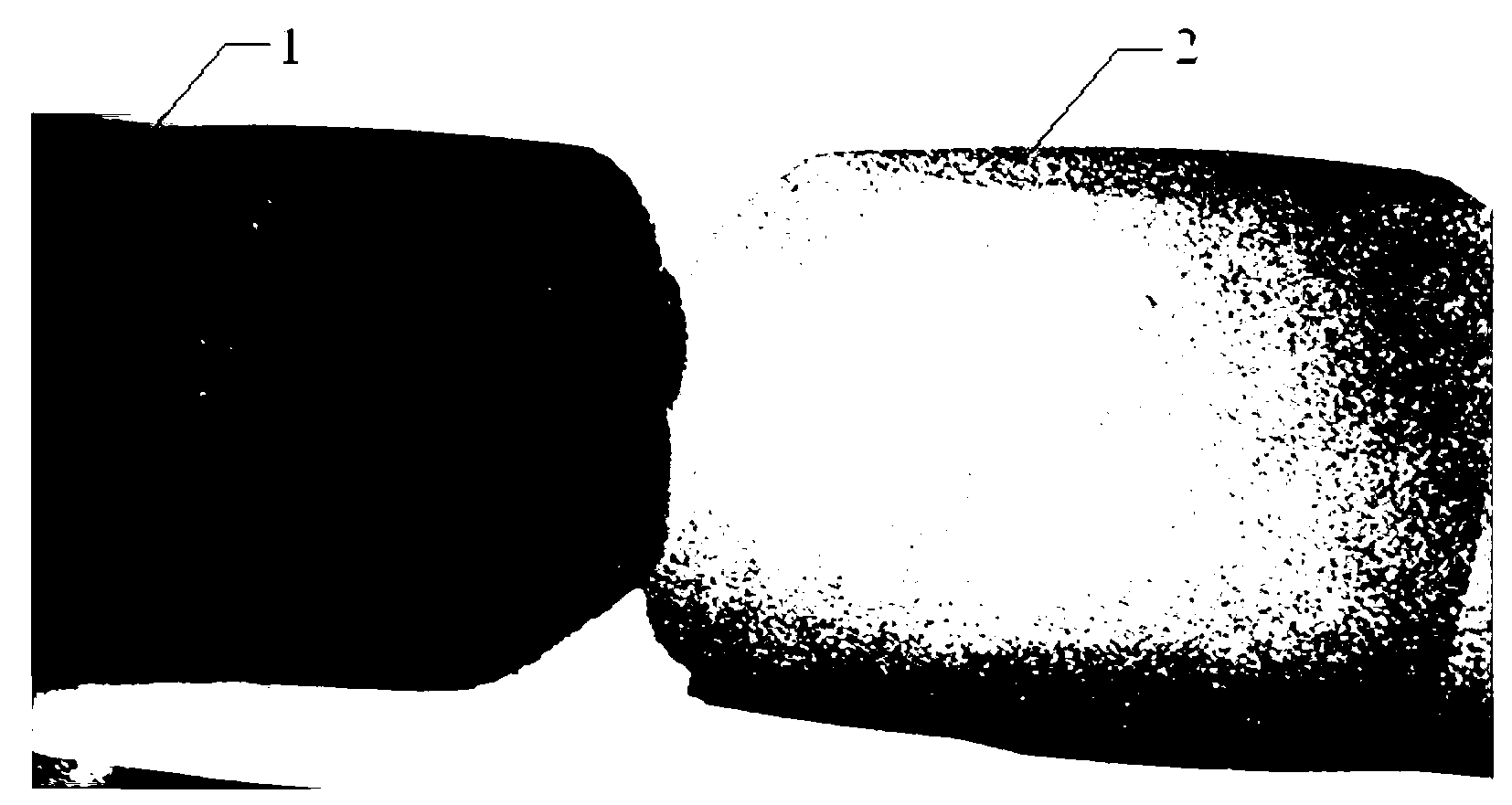

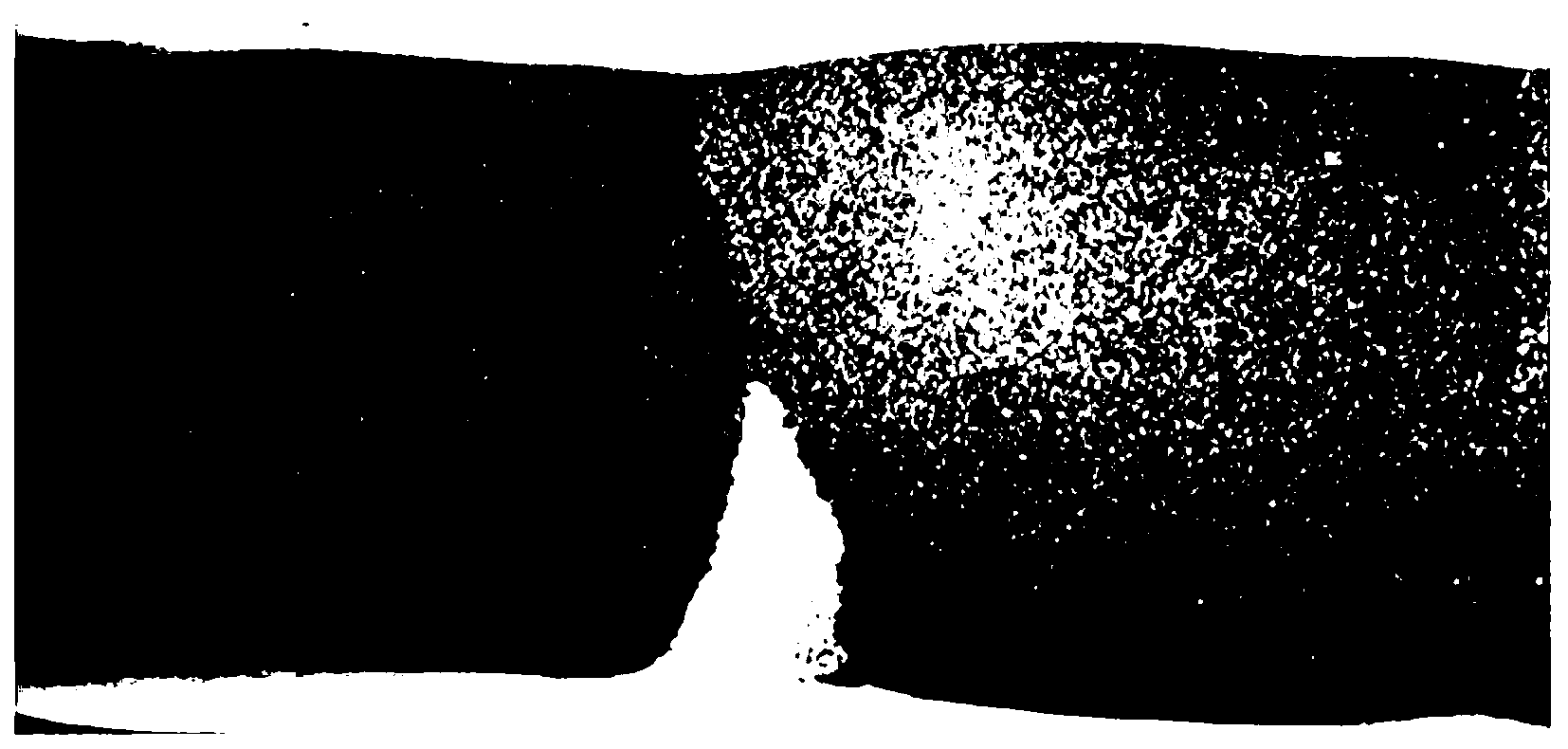

[0046] Figure 4 It is a schematic diagram of the comparison results of the sediment and overflow after the separation of ilmenite. It can be seen from the figure that the separation ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com