Electrode type sludge pressing belt

A sludge pressing and electrode-type technology, applied in the field of pressing belts, can solve problems such as easy deterioration of the working condition of the roller shaft, high operating costs, corrosion, etc., and achieve the effects of improving the pressing dehydration efficiency, good heat dissipation performance, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

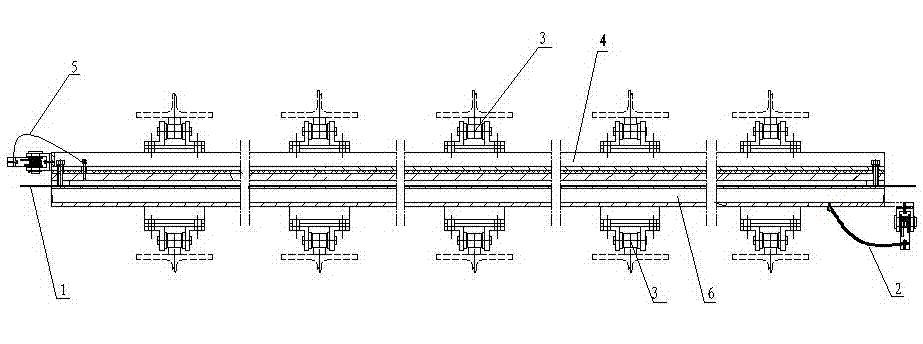

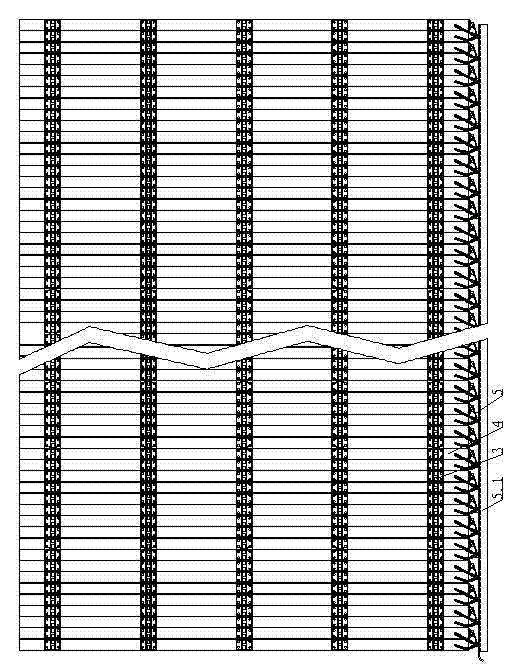

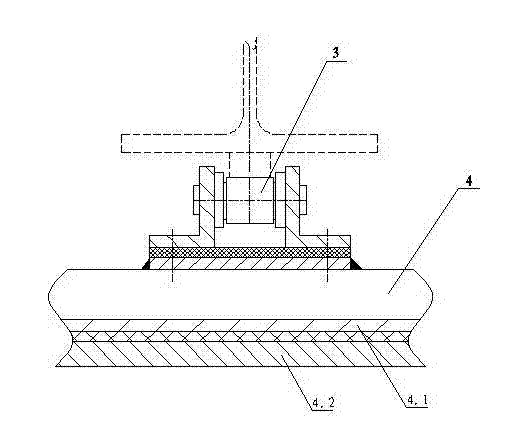

[0026] figure 1 The shown embodiment of the electrode type sludge press belt is divided into an upper press belt and a lower press belt by the flat filter belt 1 as a boundary. The upper press belt is an endless belt with a crawler structure with an amplitude of 2500 mm, which is configured in an electro-osmotic belt sludge dewatering equipment with a daily output of 40-50 tons of sludge cake. In this embodiment, as figure 2 , image 3 with Figure 4 As shown, the upper press belt is composed of five identical and alternately arranged chains 3 as a longitudinal structure, and each wing plate of the five chains 3 is connected with a transverse upper bridge plate 4 respectively. The upper bridge plate 4 of the upper press belt is made of channel steel, and its width is equal to the pitch of the sprocket 3. The upper bridge plate 4 is connected to the wing plate of the chain 3 with the notch side up. Lay the plastic plate 4.1 on the plane, and then insulate and connect the electr...

Embodiment 2

[0028] The electrode-type sludge pressing belt in this embodiment has a smaller specification with an amplitude of 500 mm. It is configured in an electro-osmotic belt-type sludge dewatering equipment with a daily output of 3 to 5 tons of sludge cake. Such as Picture 8 As shown, both the upper press belt and the lower press belt are composed of two identical and alternately arranged chains 3 as the longitudinal structure. Each wing plate of the two chains 3 is connected to the upper bridge plate 4 and the lower bridge plate 6 in the transverse direction. The structure is exactly the same as the first embodiment, only the component size is reduced in proportion, and the application effect is similar to that of the first embodiment.

[0029] In practical application of the present invention, the upper press belt and the lower press belt synchronously wind at a constant speed, enter the upper press belt and the lower press belt in the press area to obtain electricity and relatively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com