Semiconductor ceramic and multilayer semiconductor ceramic capacitor

A technology of ceramic capacitors and semiconductors, applied in the direction of multilayer capacitors, capacitors, fixed capacitors, etc., can solve the problem of lowering the dielectric constant, and achieve the effect of large-capacity multilayer semiconductor ceramic capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

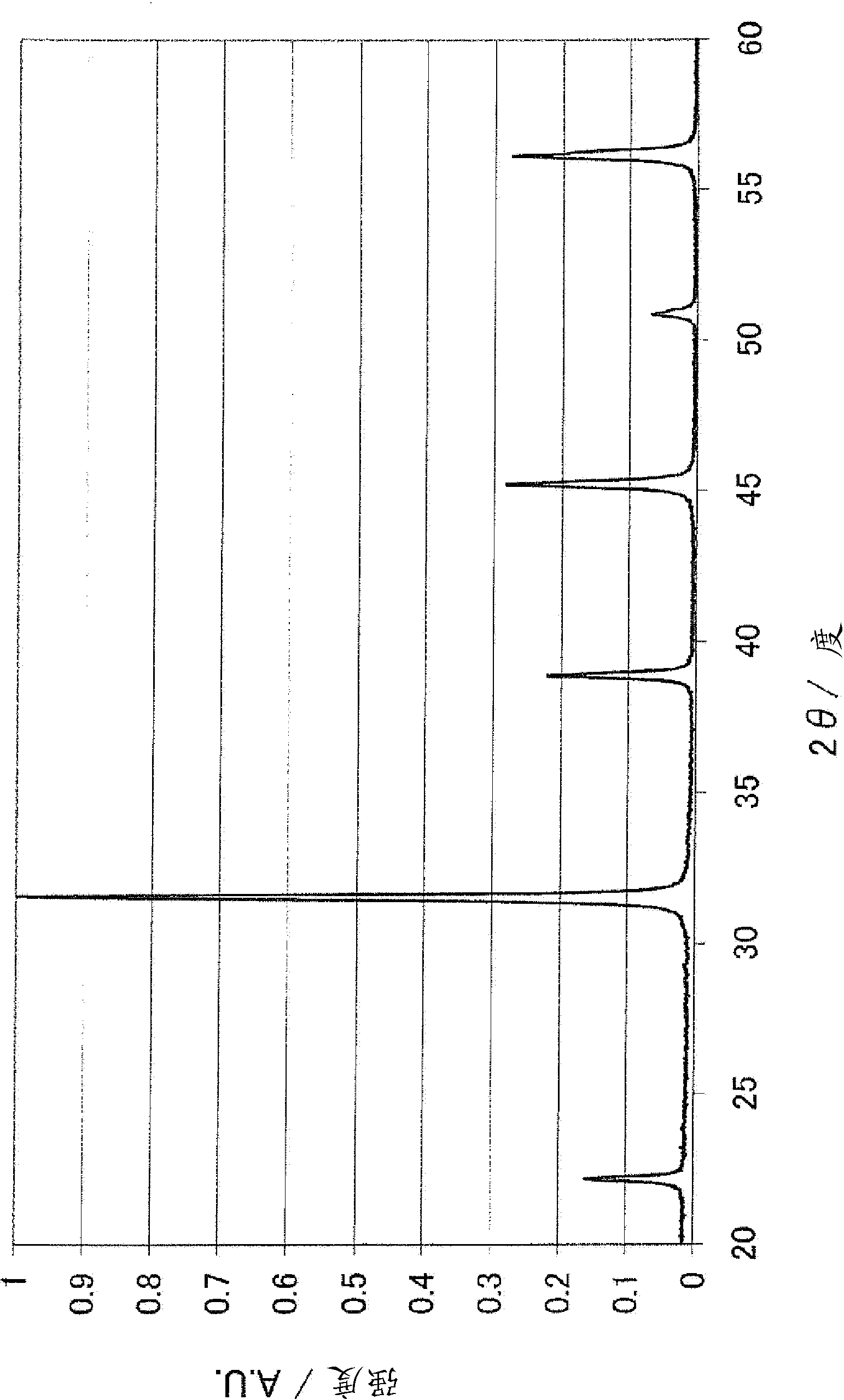

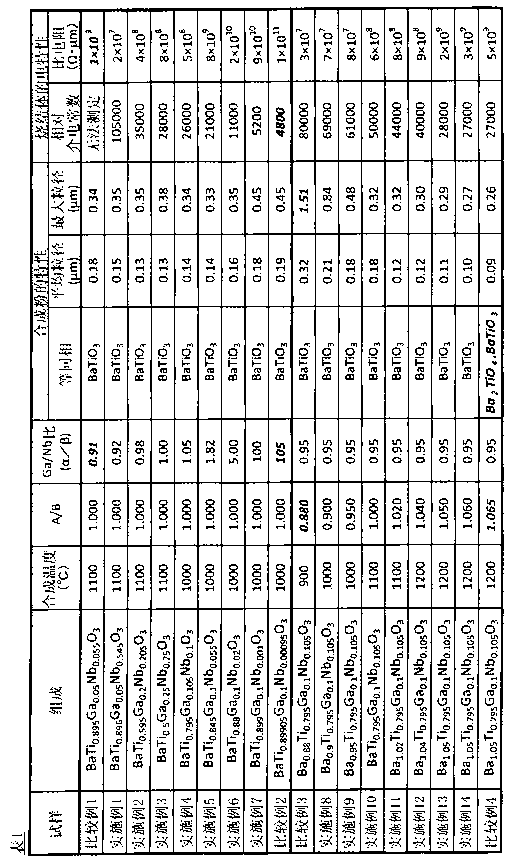

[0067] (Examples 1-14, Comparative Examples 1-4)

[0068] First, prepare BaCO as a raw material powder 3 (specific surface area: 25m 2 / g), TiO 2 (specific surface area: 50m 2 / g), Ga 2 o 3 (specific surface area: 10m 2 / g) and Nb 2 o 5 (specific surface area: 10m 2 / g), weighed according to the composition shown in Table 1.

[0069]

[0070]Next, the weighed raw material powder is mixed with water and a dispersant by a ball mill to prepare a raw material mixture. The obtained mixed powder was treated under the following heat treatment conditions to produce barium titanate-based semiconductor fine particles.

[0071] The heat treatment conditions were heating rate: 200°C / hour, holding temperature: the temperature shown in Table 1, temperature holding time: 2 hours, cooling rate: 200°C / hour, in the air.

[0072] From the above, barium titanate-based semiconductor fine particles capable of contributing to thinning of the dielectric layer can be obtained.

[0073] ...

Embodiment 15

[0090] SiO was added in such a way that it was 0.5 mol relative to 100 mol of Ti element of the synthetic powder produced in Example 10. 2 , put into a ball mill together with a dispersant, fully wet-mix in the ball mill, evaporate and dry, and then perform a heat treatment at 500° C. for about 3 hours in an air atmosphere to produce a heat-treated powder.

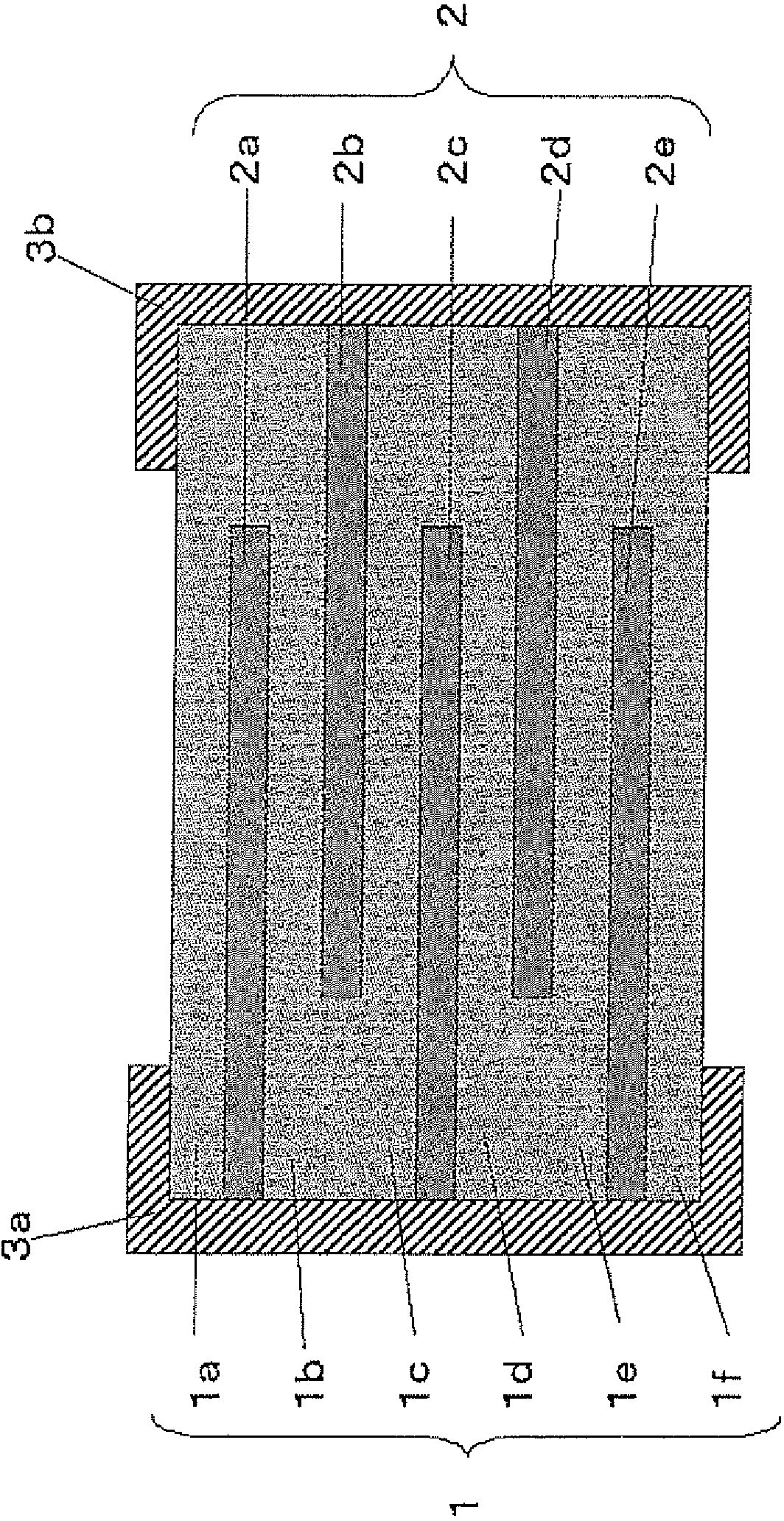

[0091] Next, 0.3 mol of Mn was added to 100 mol of Ti element in the synthetic powder, and an appropriate amount of an organic solvent such as alcohol fuel or a dispersant was added. Then, it is poured into a ball mill together with water, fully wet-mixed in the ball mill, and then an appropriate amount of an organic binder or plasticizer is added, and wet-mixed for a long enough time to obtain a ceramic slurry.

[0092] Next, the ceramic slurry was subjected to forming processing using a forming processing method such as a doctor blade method, so that the thickness after drying was 1 μm, and a ceramic green sheet was prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com