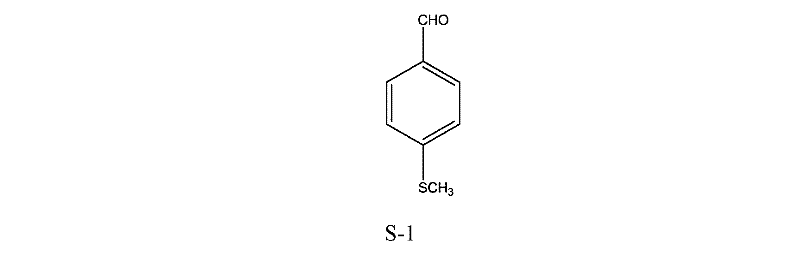

Preparation method of 4-methylthio benzaldehyde

A technology of benzaldehyde and methylthio group, applied in the field of organic compound synthesis, can solve the problems of unfavorable environment, increased production cost and high reaction temperature, and achieves the effects of reduced production cost, no three waste emissions and high economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

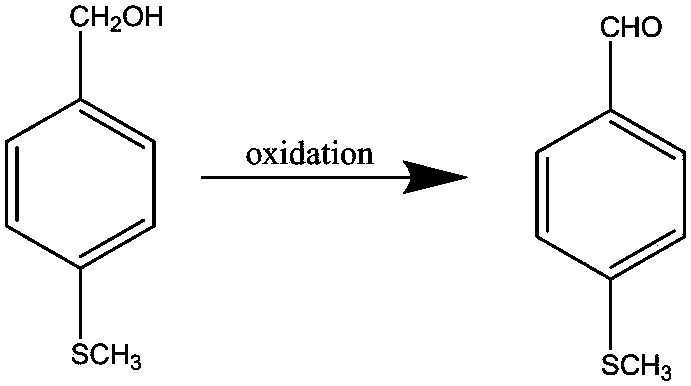

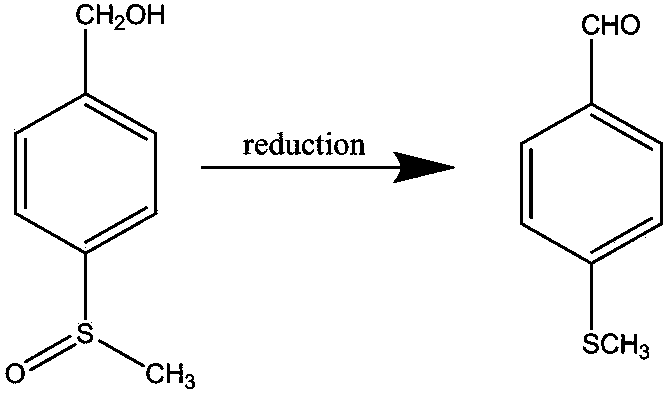

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, a kind of preparation method of 4-methylthiobenzaldehyde, take thioanisole as raw material, carry out the following steps successively:

[0043] 1) Preparation of SZTA catalyst:

[0044] ①、TiCl 4 and ZrOCl 2 ·8H 2 O mixed to get a mixed solution; ZrOCl 2 ·8H 2 Zr atoms in O and TiCl 4 The ratio of the atomic number of Ti atoms in is 10:1; that is, nZr:nTi=10:1;

[0045] ②. Under rapid stirring (100 rpm), add ammonia water with a concentration of 1mol / L dropwise into the mixed solution obtained in step ① until the pH value is 9, and the resulting reaction system will appear precipitation. The reaction system containing precipitation Aged at room temperature for 24 h; filtered, and the resulting aged precipitate was washed repeatedly until the washing liquid did not contain Cl - until;

[0046] ③. Dry the washed precipitate obtained in step ② at 110°C for 8 hours, cool to room temperature, and grind it into a powder with a particle size of less than...

Embodiment 2

[0050] Embodiment 2, a kind of preparation method of 4-methylthiobenzaldehyde, take thioanisole as raw material, carry out the following steps successively:

[0051] 1) Preparation of SZTA catalyst:

[0052] ①、TiCl 4 and ZrOCl 2 ·8H 2 O mixed to get a mixed solution; ZrOCl 2 ·8H 2 Zr atoms in O and TiCl 4 The ratio of the atomic number of Ti atoms in is 20:1; that is, nZr:nTi=20:1;

[0053] ②. Under rapid stirring (100 rpm), add ammonia water with a concentration of 1 mol / L dropwise to the mixed solution obtained in step ① until the pH value is 9, and the resulting reaction system will appear precipitation. The reaction system containing precipitation is in Aged at room temperature for 24 h; filtered, and the resulting aged precipitate was washed repeatedly until the washing liquid did not contain Cl - until;

[0054] ③. Dry the washed precipitate obtained in step ② at 110°C for 8 hours, cool to room temperature, and grind it into a powder with a particle size of less...

Embodiment 3

[0058] Embodiment 3, a kind of preparation method of 4-methylthiobenzaldehyde, take thioanisole as raw material, carry out the following steps successively:

[0059] 1) Preparation of SZTA catalyst:

[0060] With embodiment 1.

[0061] 2) Weigh 2g of the SZTA catalyst obtained in step 1) and place it in a 50ml stainless steel autoclave lined with polytetrafluoroethylene, add 12ml (0.1mol) thioanisole; the mixture composed of SZTA catalyst and thioanisole After heating to 80°C, feed CO to make the pressure in the autoclave 0.5 MPa, keep warm (80°C) and react for 3 hours. Introduce 50ml of water into the filtrate, stir at 100 rpm for 30min, and the solid obtained is 4-methylthiobenzaldehyde. Finally, 12.2 g of 4-methylthiobenzaldehyde was obtained, and the yield was 80.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com