Edible inulin composite packaging film, preparation method and application thereof

A technology of composite packaging film and inulin, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of inability to use large-scale food packaging, difficulty in meeting food packaging, small production scale, etc., and achieve enhanced intestinal function, The effect of low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

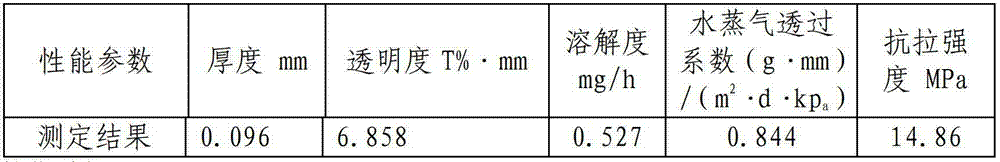

Embodiment 1

[0017] In terms of mass percentage, 2% inulin, 0.5% sodium alginate, and 3% plasticizer glycerin are fully dissolved in water, and the mixed solution is placed in a 60°C constant temperature water bath and heated and stirred until it becomes a lump-free glue liquid. After stirring, stand at room temperature for 12-24h for degassing treatment; the degassed solution is poured on a glass plate to ensure the thickness of the film. Put the glass plate with the film poured into a 60°C constant temperature blast drying oven to dry. The dried glass plate with film is immersed in 5% calcium chloride cross-linking agent for crosslinking for 1-5min, and then placed in an oven at 40-60°C for drying. After drying, place the filmed glass plate in saturated nitric acid Soften in the desiccator of the magnesium solution for 24-36 hours, and finally peel off the film to obtain the edible inulin composite packaging film. The film-forming properties are shown in Table 1.

[0018] The performan...

Embodiment 2

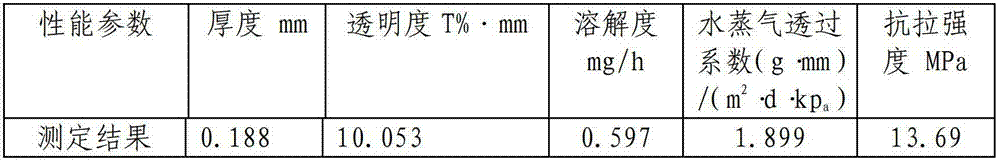

[0027] In terms of mass percentage, 5% inulin, 2.5% sodium alginate, and 1% plasticizer glycerin are fully dissolved in water, and the mixed solution is placed in a 60°C constant temperature water bath and heated and stirred until it becomes a lump-free glue liquid. After stirring, stand at room temperature for 12-24h for degassing treatment; the degassed solution is poured on a glass plate to ensure the thickness of the film. Put the glass plate with the film poured into a 60°C constant temperature blast drying oven to dry. The dried glass plate with film is immersed in 3% calcium chloride cross-linking agent for cross-linking for 1-5min, and then placed in an oven at 40-60°C for drying. After drying, place the filmed glass plate in saturated nitric acid Soften in the desiccator of the magnesium solution for 24-36 hours, and finally peel off the film to obtain the edible inulin composite packaging film. The film-forming properties are shown in Table 2.

[0028] The performa...

Embodiment 3

[0037] In terms of mass percentage, 10% inulin, 1.5% sodium alginate, and 1% plasticizer glycerin are fully dissolved in water, and the mixed solution is placed in a 60°C constant temperature water bath and heated and stirred until it becomes a lump-free glue liquid. After stirring, stand at room temperature for 12-24h for degassing treatment; the degassed solution is poured on a glass plate to ensure the thickness of the film. Put the glass plate with the film poured into a 60°C constant temperature blast drying oven to dry. The dried glass plate with film is immersed in 5% calcium chloride cross-linking agent for crosslinking for 1-5min, and then placed in an oven at 40-60°C for drying. After drying, place the filmed glass plate in saturated nitric acid Soften in the desiccator of the magnesium solution for 24-36 hours, and finally peel off the film to obtain the edible inulin composite packaging film. The film-forming properties are shown in Table 3.

[0038] The performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com