Organic Rankine cycle mixed refrigerant containing HFO-1234yf(CF3CF=CH2)

A technology of mixed working fluid and Rankine cycle, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of inflammability and explosion, poor economy, large greenhouse effect, etc., and achieve excellent cycle performance and environmental characteristics excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

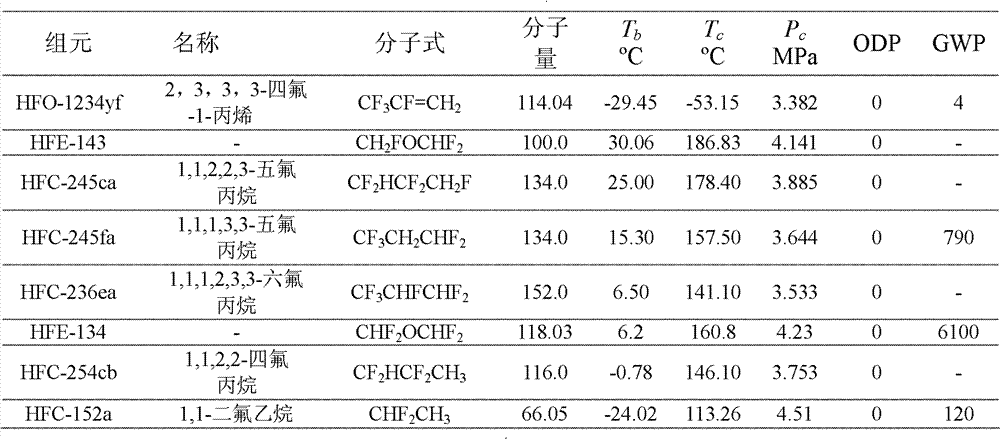

Method used

Image

Examples

Embodiment 1

[0021] Example 1: take 1 mass %HFO-1234yf, 2 mass %HFC-152a and 83 mass %HFC-254cb, used as a refrigerant after physical mixing at room temperature.

Embodiment 2

[0022] Embodiment 2: get 38 mass %HFO-1234yf, 10 mass %HFC-152a and 52 mass %HFC-254ca, used as a refrigerant after physical mixing at room temperature.

Embodiment 3

[0023] Embodiment 3: get 12 mass %HFO-1234yf, 5 mass %HFC-152a and 83 mass %HFC-236ea, used as a refrigerant after physical mixing at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com