Papermaking method by oxidizing banana stemfiber

A technology of banana stems and fibers, applied in the post-processing of cellulose pulp, papermaking, textiles and papermaking, etc., to achieve the effects of improved pulp yield, high yield and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

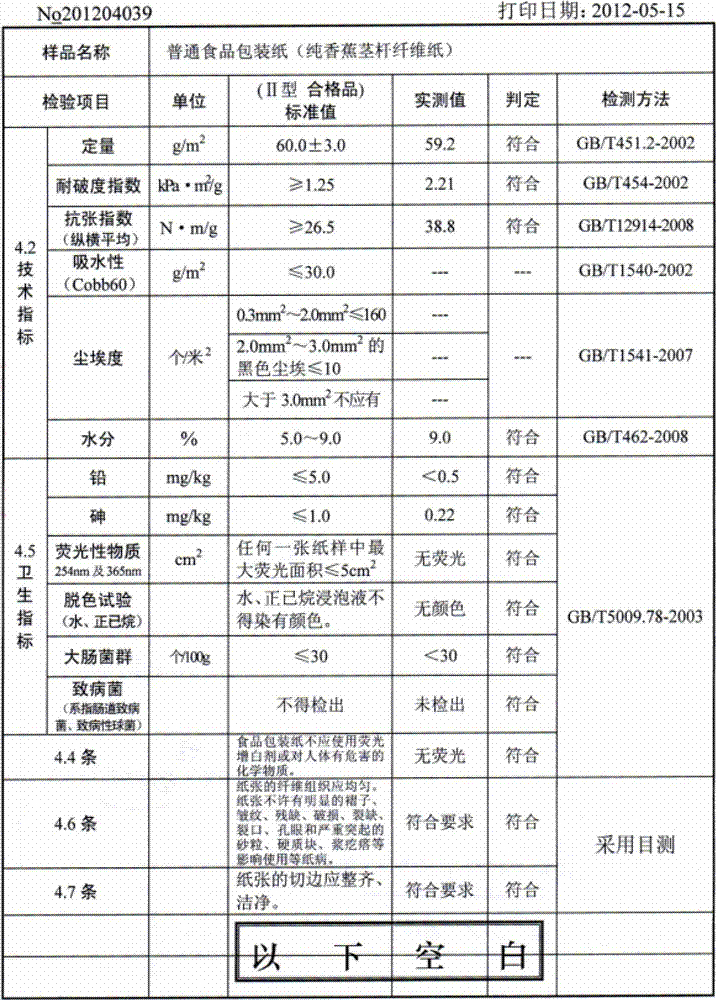

Image

Examples

Embodiment 1

[0016] 1. Slicing:

[0017] 1000 kilograms of fresh banana stalks after harvesting are collected and cut into 5 × 7 cm slices with a slicer, and then the sheet-shaped stalks are roughly ground into fiber slurry with a coarse grinder for pulping in a paper mill.

[0018] 2. Washing:

[0019] After being transported to a continuous hydropulper with a volume of 5 cubic meters by a screw machine for cleaning, it flows into a vibrating screen with an aperture of 6 mm for washing, and the hemicellulose, lignin and pectin are washed away by washing.

[0020] 3. Squeeze:

[0021] After washing, an extruder is used to extrude the fiber slurry with a water content of 50-60%.

[0022] 4. Oxidation:

[0023] Put the extruded fiber slurry into a circular carbon steel container with a volume of 5 cubic meters, add 10 kg of quicklime with a pH value of 7-8, and stir for 20-30 minutes. At the same time, slowly add sodium hypochlorite with a content of 85% to 5-7% of the quality of the fib...

Embodiment 2

[0027] 1. Slicing: Collect 2,000 kg of fresh banana stems after harvesting and cut them into 5×7cm slices with a slicer, and then use the coarse grinder used in paper mills to roughly grind the sliced stems into fiber pulp material;

[0028] 2. Washing:

[0029] After being transported to a continuous hydropulper with a volume of 5 cubic meters by a screw machine for cleaning, it flows into a vibrating screen with an aperture of 6 mm for washing, and the hemicellulose, lignin and pectin are washed away by washing.

[0030] 3. Squeeze:

[0031] After washing, an extruder is used to extrude the fiber slurry with a water content of 50-60%.

[0032] 4. Oxidation:

[0033] Put the extruded fiber slurry into a circular carbon steel container with a volume of 5 cubic meters, add 20 kg of quicklime with a pH value of 7-8, and stir for 20-30 minutes. At the same time, slowly add sodium hypochlorite with a content of 85% to 5-7% of the quality of the fiber slurry with a water cont...

Embodiment 3

[0037] 1. Slicing:

[0038] Collect 5,000 kg of harvested banana stems and cut them into 5×7 cm slices with a slicer, and then coarsely grind the sliced banana stems with a coarse grinder commonly used in paper mills for pulping.

[0039] 2. Washing:

[0040] After being transported to a continuous hydropulper with a volume of 5 cubic meters by a screw machine for cleaning, it flows into a vibrating screen with an aperture of 6 mm for washing, and the hemicellulose, lignin and pectin are washed away by washing.

[0041] 3. Squeeze:

[0042] After washing, an extruder is used to extrude the fiber slurry with a water content of 50-60%.

[0043] 4. Oxidation:

[0044] Put the extruded fiber slurry into a circular carbon steel container with a volume of 5 cubic meters, add 50 kg of quicklime with a pH value of 7-8, and stir for 20-30 minutes. At the same time, slowly add sodium hypochlorite with a content of 85% to 5-7% of the quality of the fiber slurry with a moisture cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com