Hollow interior formwork expanded metal lath cement anti-seismic heat-preservation-wall interior wall

A technology of expanded metal and thermal insulation walls, applied in the direction of thermal insulation, walls, and earthquake resistance, which can solve problems such as poor material quality, wall safety, hidden dangers of repair and maintenance, and large shrinkage, so as to improve crack and earthquake resistance and construction operation procedures Simple, fast, reasonable and compact, the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

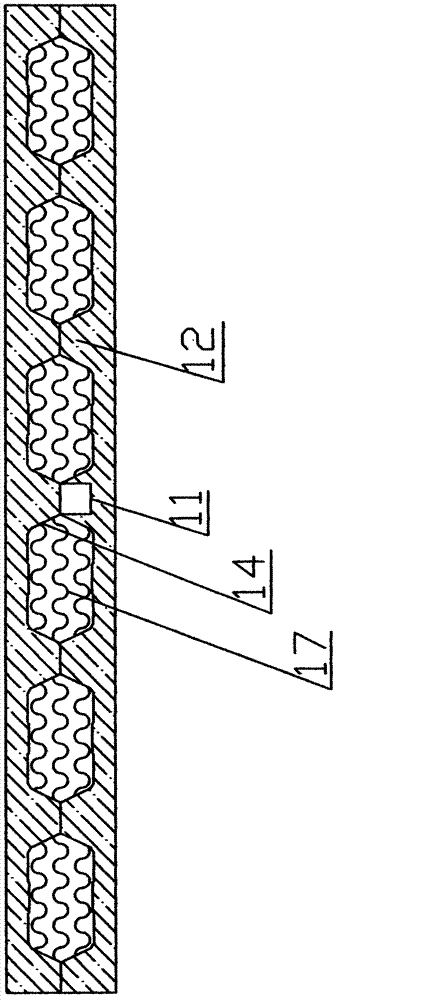

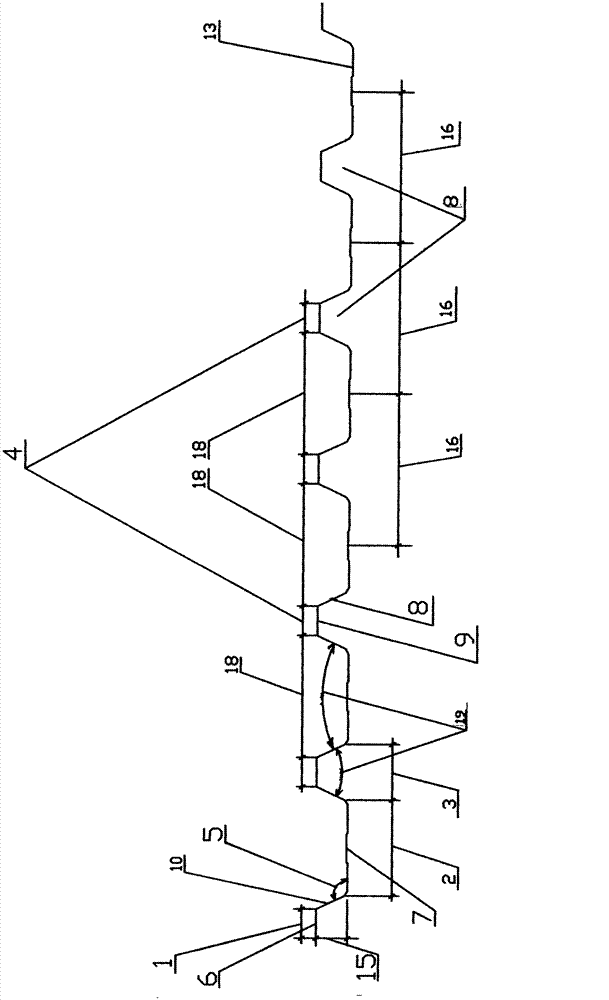

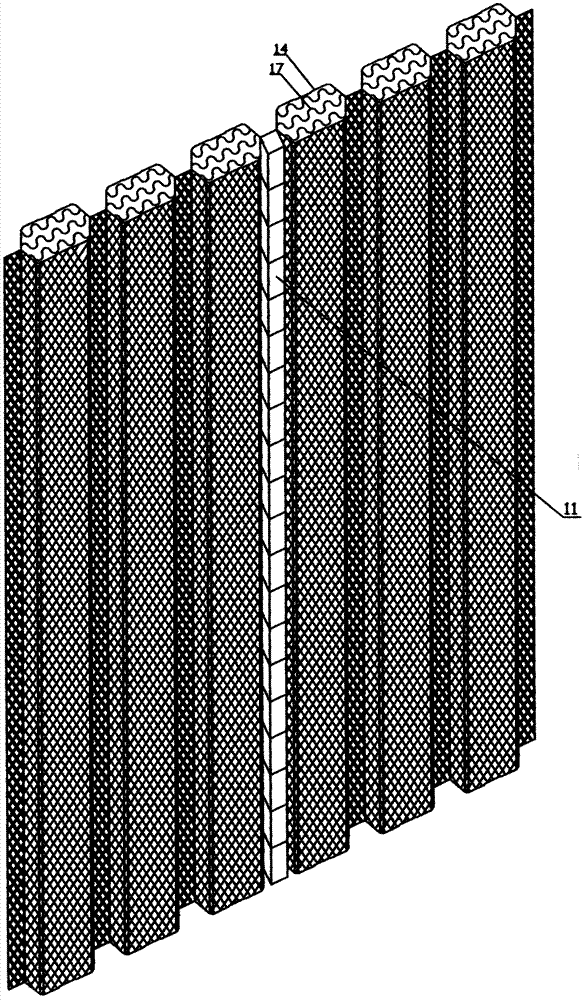

[0016] according to Figure 1-Figure 3 As shown, the present invention mainly includes: interface side length 1, convex side length 2, outer groove width 3, inner groove width 4, angle 5 between convex surface 7 and convex edge 10, interface 6, convex surface 7, outer groove 8, inner Groove 9, convex edge 10, vertical keel square steel pipe 11, outer layer 12, expanded metal mesh 13, channel 14, height 15 of convex edge 10 and outer groove 8, distance 16 between midpoints of two convex surfaces 7, flame retardant glass Cotton 17, inner notch width 18, the included angle 19 of two convex edges 10.

[0017] The inner wall of the hollow inner mold expanded metal cement anti-seismic insulation wall includes: expanded metal 13, flame-retardant glass wool 17, outer layer 12; expanded metal 13 includes: interface 6, convex surface 7, outer groove 8, inner groove 9, convex edge 10 The interface 6 is symmetrically arranged at both ends of the steel mesh 13, and the interface 6 is fixe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap