Method for forming semiconductor structure

A semiconductor and stacked structure technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as shrinkage, achieve good sidewall morphology, improve efficiency, and reduce etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0067] refer to Figure 9 , Figure 9 It is a schematic flowchart of a method for forming a semiconductor structure according to the second embodiment of the present invention, including:

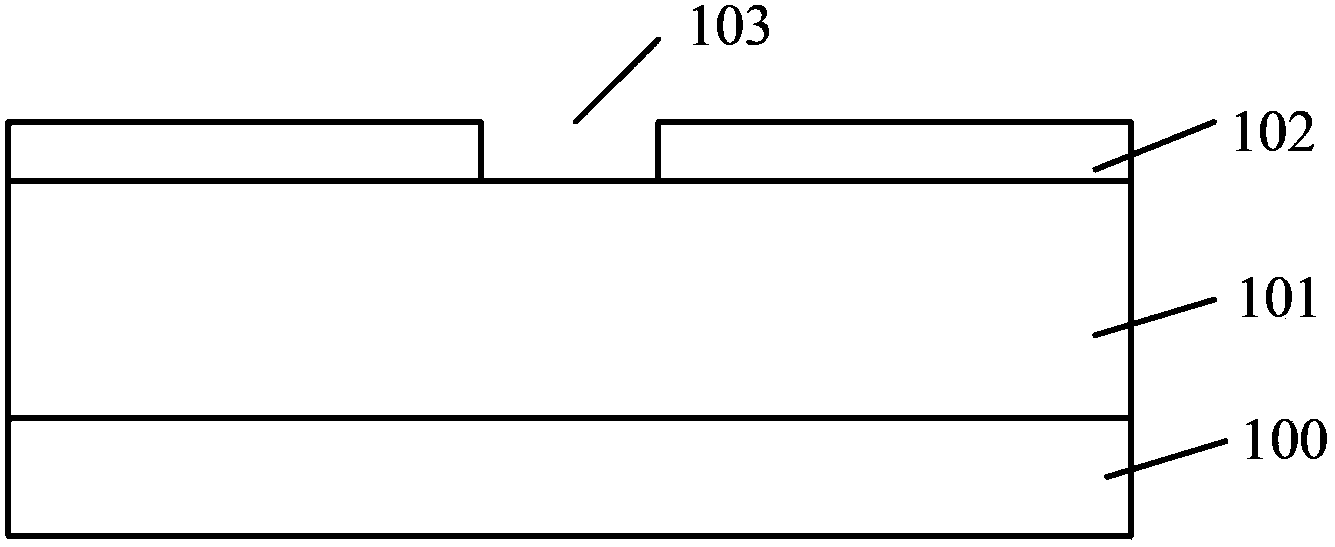

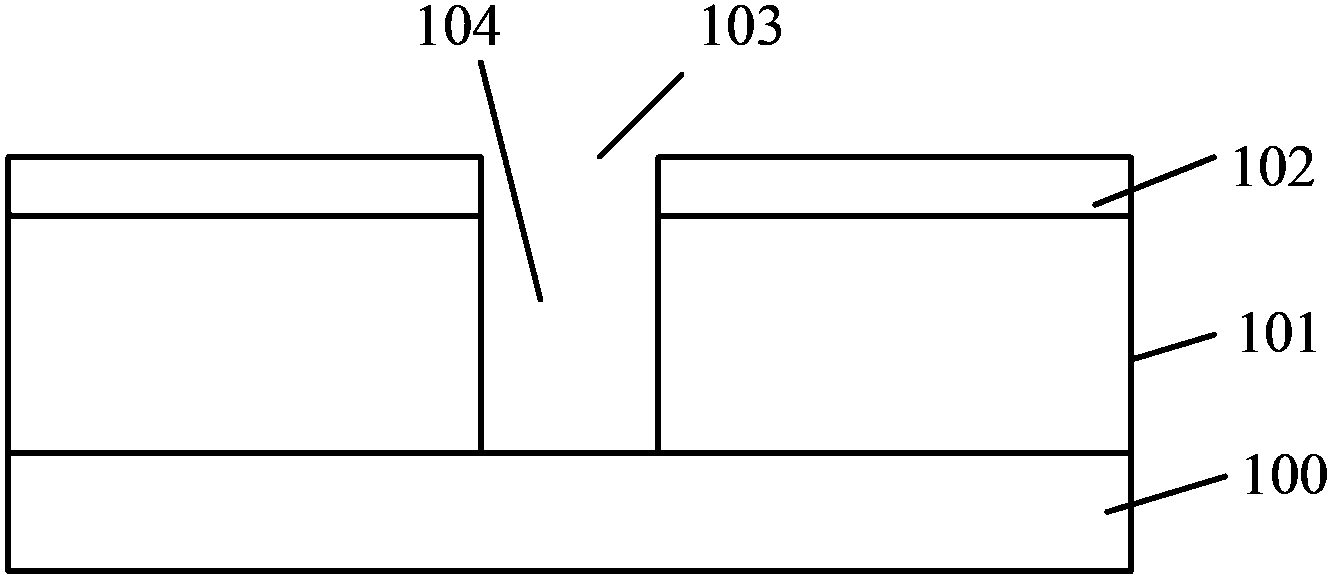

[0068] Step S31, providing a substrate, forming a multi-layer stack structure in which silicon nitride layers and silicon oxide layers are alternately distributed on the substrate, forming a mask layer on the surface of the stack structure, and the mask layer has a surface that exposes the stack structure surface open mouth

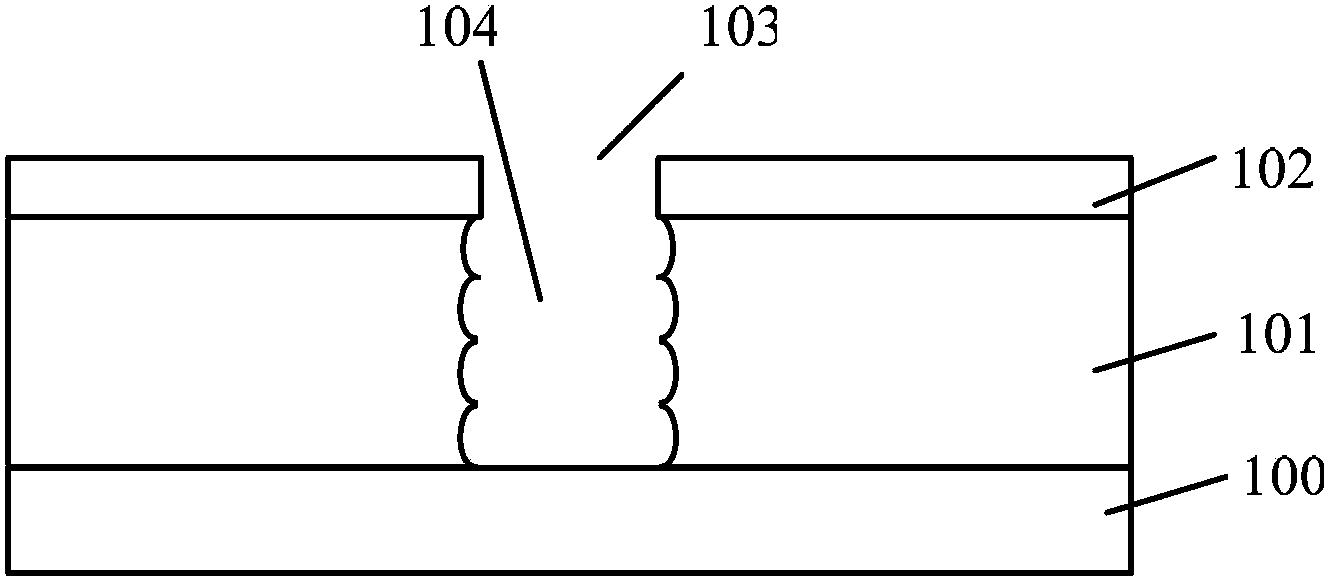

[0069] Step S32, performing plasma etching on the stacked structure, the bias power source outputs bias power in a pulsed manner, the plasma etching is a plasma etching with a continuously decreasing duty cycle, when the bias power When the source is turned on, part of the stacked structure is etched to form an etching hole; when the bias power source is turned off, a polymer is formed on the sidewall and bottom of the formed etching hole, and the bias power source i...

no. 3 example

[0087] refer to Figure 14 , Figure 14 It is a schematic flowchart of a method for forming a semiconductor structure according to the third embodiment of the present invention, including:

[0088] Step S41, providing a substrate, forming a multi-layer stack structure in which silicon nitride layers and silicon oxide layers are alternately distributed on the substrate, forming a mask layer on the surface of the stack structure, and the mask layer has a surface that exposes the stack structure surface open mouth

[0089] Step S42, using plasma with a constant duty ratio to etch the stacked structure to form a first etching hole;

[0090] In step S43 , along the first etching hole, the stack structure is etched with a plasma having a continuously decreasing duty cycle to form a second etching hole, and the first etching hole and the second etching hole form a through hole.

[0091] Figure 15~Figure 17 It is a schematic cross-sectional structure diagram of the formation proc...

no. 4 example

[0110] refer to Figure 18 , Figure 18 It is a schematic flowchart of a method for forming a semiconductor structure according to a fourth embodiment of the present invention, including:

[0111] Step S51, providing a substrate, forming a multi-layer stack structure in which silicon nitride layers and silicon oxide layers are alternately distributed on the substrate, forming a mask layer on the surface of the stack structure, and the mask layer has a surface exposed to the stack structure. open mouth

[0112] Step S52, using a continuous plasma etching process to etch the stacked structure to form a third etching hole;

[0113] Step S53, then performing plasma etching in which the bias power source outputs bias power in a pulsed manner to the stacked structure along the third etching hole to form a fourth etching hole, a third etching hole and a fourth etching hole form a through hole.

[0114] Figure 19~Figure 21 It is a schematic cross-sectional structure diagram of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com