Gunn diode, preparation method and millimeter wave oscillator thereof

A millimeter-wave oscillator and Gunn diode technology, applied in resonators, waveguide devices, body negative resistance effect devices, etc., can solve the problems of multi-waveguide cavities with complex structures, complex circuits, and large footprints, and achieve high resolution. Low frequency output power, increased output power and high working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The present invention is described in detail by taking an InP Gunn diode, its preparation method and a millimeter-wave oscillator based on the Gunn diode as examples.

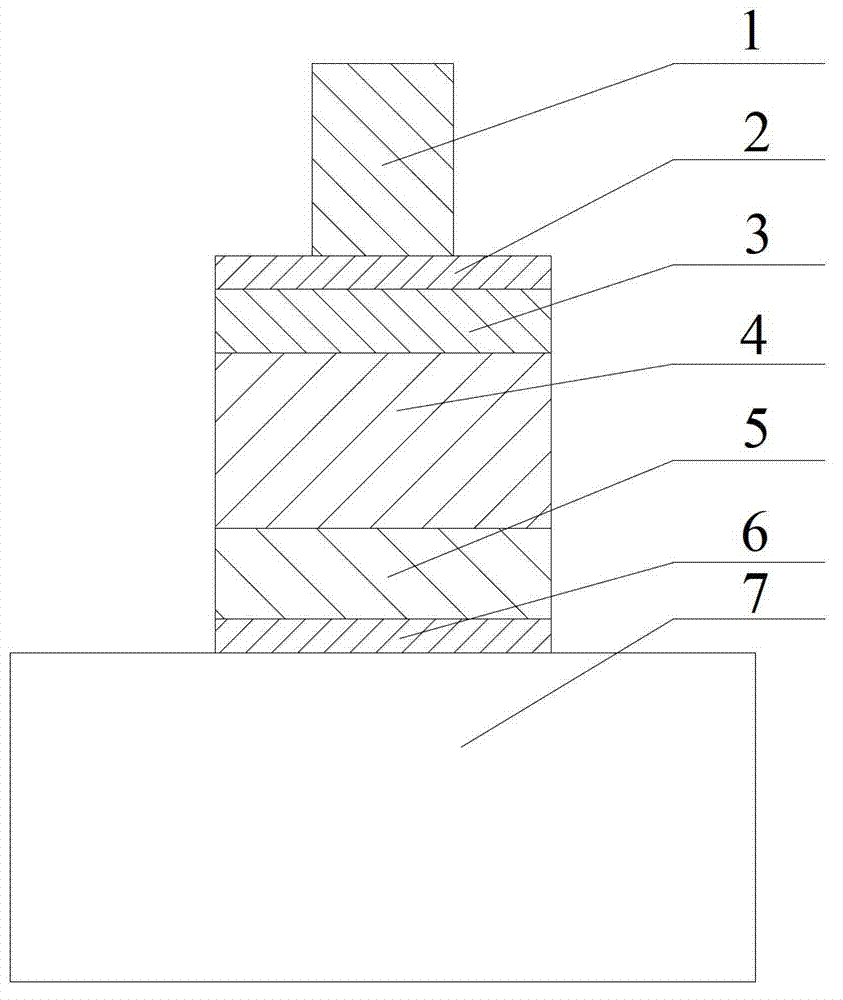

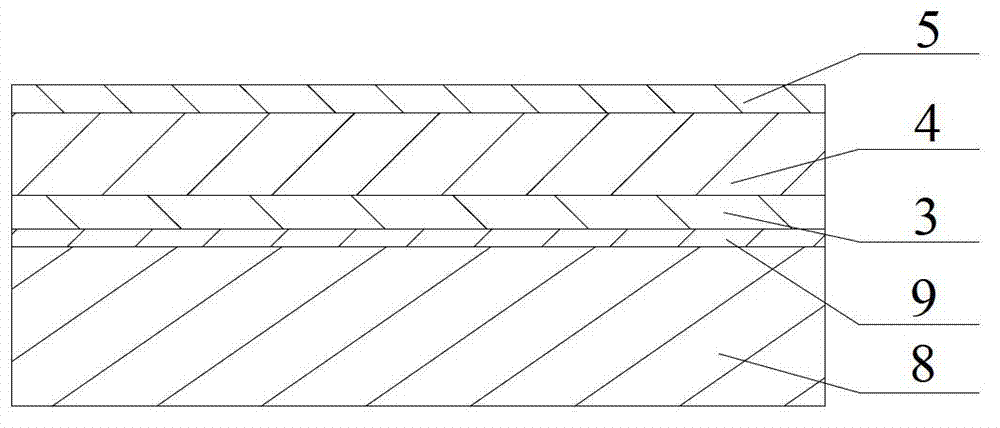

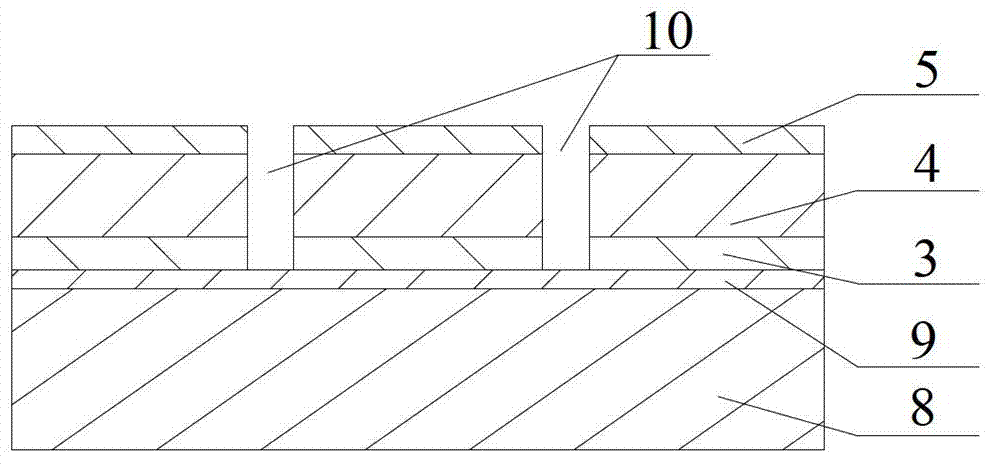

[0033] See attached figure 1 The InP Gunn diode provided by the present invention includes an integrated heat sink 7 , a deposition electrode 6 , an InP transition layer 4 , an InP second contact layer 3 , a top electrode 2 and a gold thickened electrode 1 from bottom to top.

[0034] Wherein, an InP first contact layer 5 is also included between the metal electrode and the transition layer.

[0035] Among them, the material of the integrated heat sink 7 can be gold, and the thickness can be 25 μm; the components and their ratios in the deposition electrode 6 can be Ni:Ge:Au:Ge:Ni:Au=40:40:660:80:30 : The thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com