Photovoltaic cell having a substrate glass made of aluminosilicate glass

一种硅铝酸盐玻璃、光伏电池的技术,应用在光伏发电、电路、电气元件等方向,能够解决玻璃不具有物理性质、抗结晶性没有表现出令人满意等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

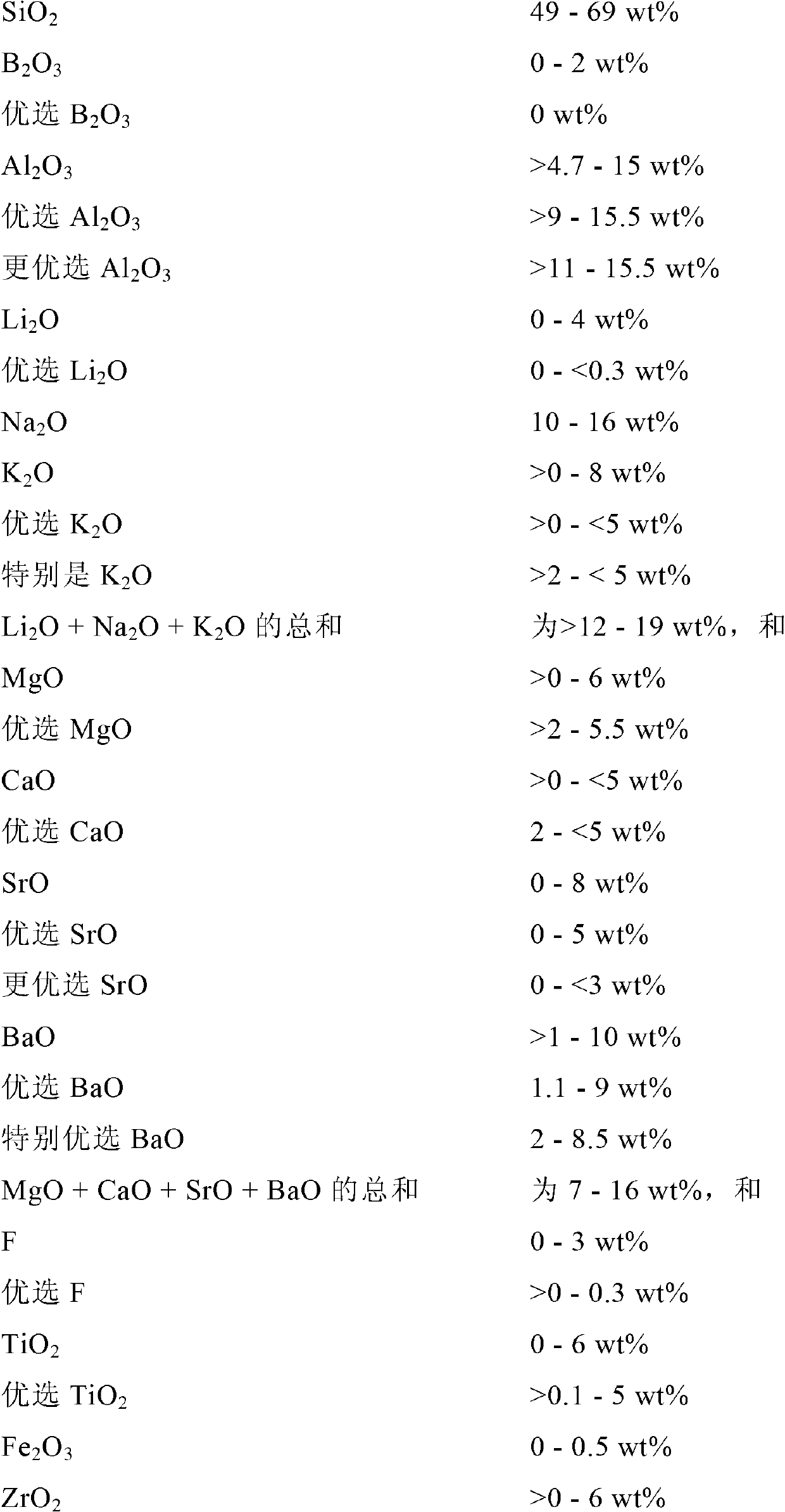

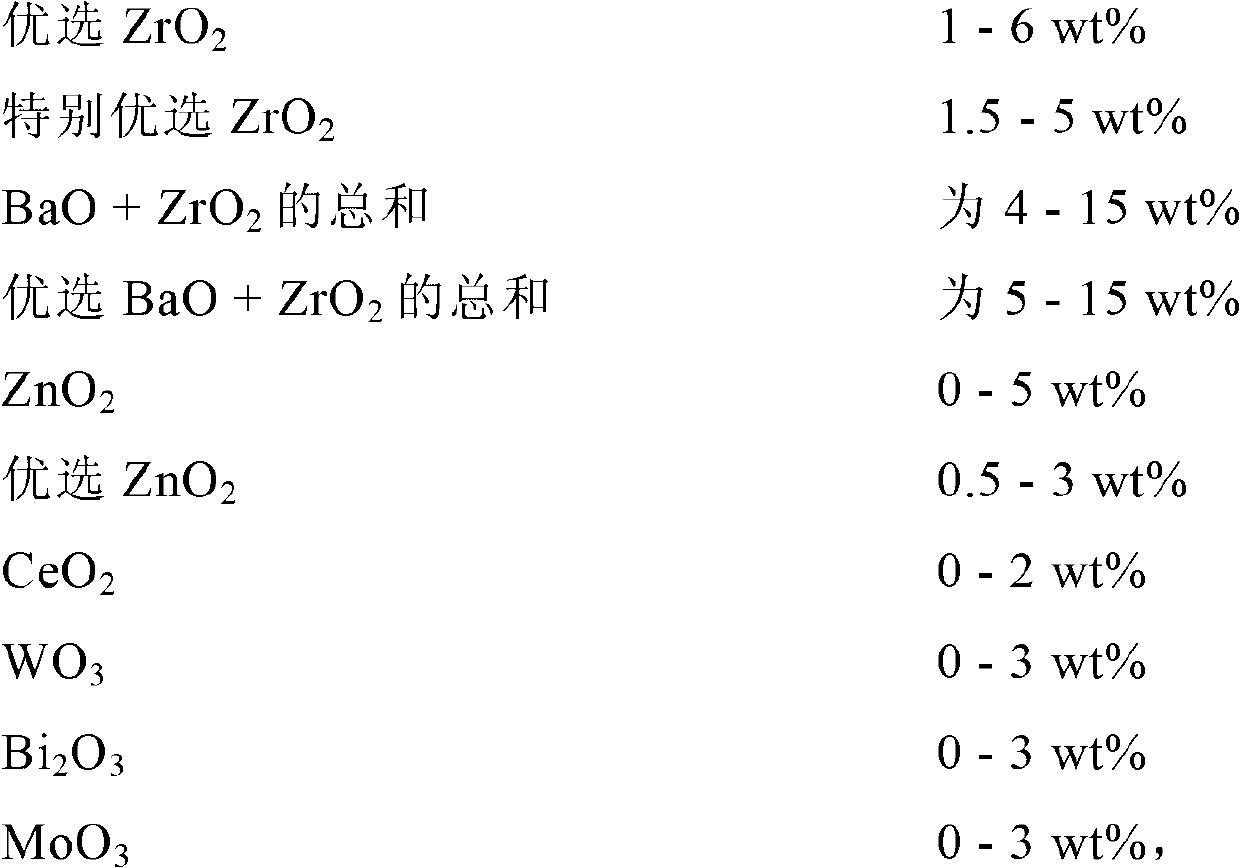

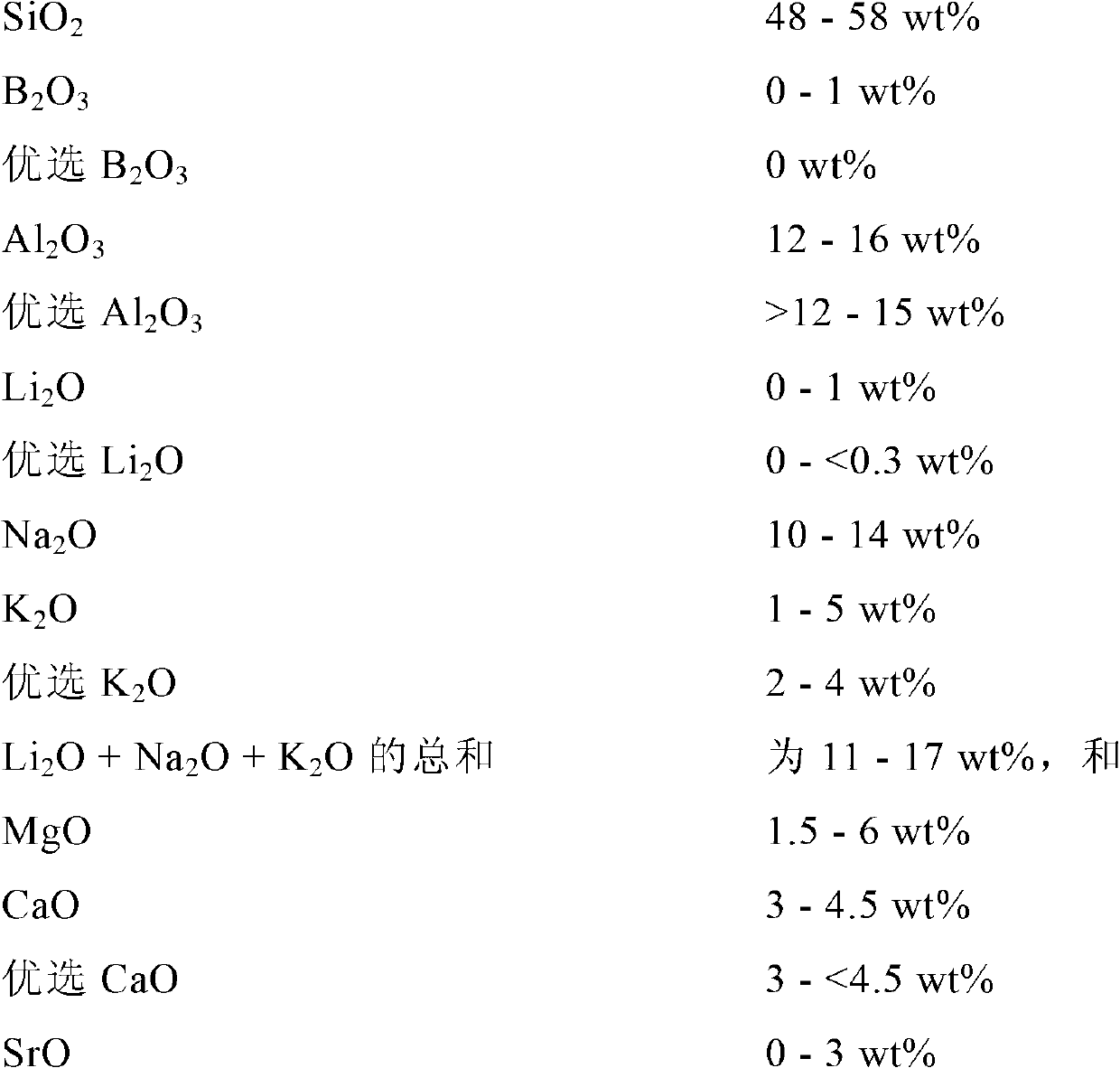

[0081] Within the scope of the teaching of the present invention, glass compositions were selected for Examples 1 to 16 and glasses were produced therefrom. For this purpose, a 1 liter platinum crucible was used for the melting, in which the raw material was brought to a melting temperature of 1580° C. over 3 hours and held at this temperature with stirring for 4 hours in the crucible. Subsequently, the melt was poured into a graphite mold preheated to 500°C. After casting, the casting mold was placed in a cooling furnace preheated to 650° C., and the cooling furnace was cooled to room temperature at 5° C. / hour. The glass compositions of Comparative Examples 1 to 3 were similarly produced. The compositions and properties of the glasses used in Examples 1 to 16 within the teaching of the present invention and the compositions of Comparative Examples 1 to 3 are summarized in Tables 1 to 4 below:

[0082] Table 1

[0083]

[0084] n.d. = Not measured devitrification (accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com