Alcohol group casting coating with both dry-wet indication function and sintering peeling function and production process thereof

A casting coating and production process technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of casting pores, easy peeling, slag inclusion, etc., achieve good anti-sticking sand performance, rich raw materials, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention takes refractory material, suspending agent, sintering agent, binding agent, indicator, industrial alcohol and Virahol as raw materials, and the percentage by mass of the present embodiment is:

[0042]

[0043] Main operation steps:

[0044] (1) Moisten the hectorite powder and attapulgite powder with an appropriate amount of water, then add industrial alcohol and isopropanol, and stir in a high-speed mixer for 20 minutes.

[0045] (2) Add quartz sand powder, high-alumina bauxite powder, mullite powder, and diatomaceous earth powder, and stir in a high-speed mixer for 30 minutes.

[0046] (3) Add phenolic resin, rosin (liquid), bromocresol green, and stir in a high-speed mixer for 15 minutes.

[0047] (4) Use a colloid mill to grind the material once and pack it.

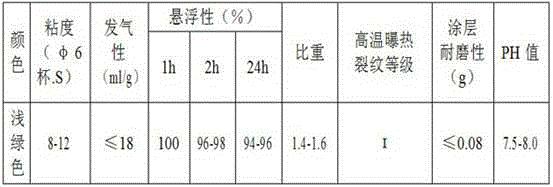

[0048] Product quality inspection results:

[0049]

Embodiment 2

[0051] The present invention takes refractory material, suspending agent, sintering agent, binding agent, indicator, industrial alcohol and Virahol as raw materials, and the percentage by mass of the present embodiment is:

[0052]

[0053] The main operation steps are operated according to the main operation steps of Embodiment 1.

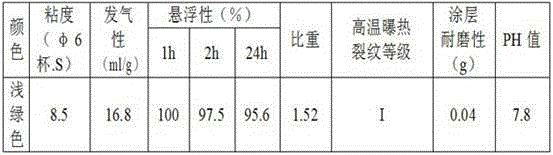

[0054] Product quality inspection results:

[0055]

Embodiment 3

[0057] The present invention takes refractory material, suspending agent, sintering agent, binding agent, indicator, industrial alcohol and Virahol as raw materials, and the percentage by mass of the present embodiment is:

[0058]

[0059] The main operation steps are operated according to the main operation steps of Embodiment 1.

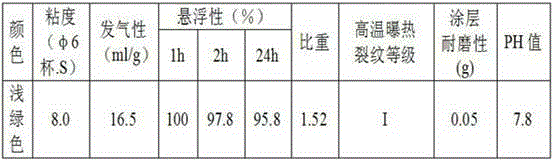

[0060] Product quality inspection results:

[0061]

[0062] In the present invention, when the paint is completely dried after ignition and combustion, the surface of the coating will show light yellow; if the paint is not completely burnt and dried, it will show green sky blue at the place where the paint is not completely burnt and dried, and the darker the color, the less dry; when the paint is ignited After burning and drying, put it for a period of time, the surface of the paint will be damp, and it will show green sky blue at the damp place, and the darker the color, the more damp it will be, and light yellow will appear at the place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com