PH responsive cigarette filter tip functional material and preparation method thereof, and cigarette filter tip

A cigarette filter and functional material technology, applied in the field of cigarette filters, can solve the problems of not being able to effectively reduce the release of harmful components in smoke, poor adsorption capacity, etc., achieve outstanding harm reduction effects, reduce release, and strengthen selective adsorption The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

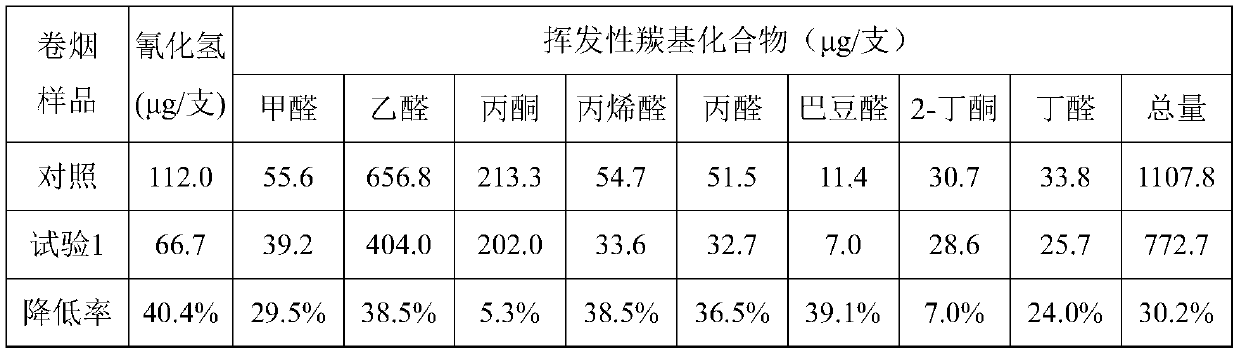

Embodiment 1

[0040] Example 1 of the preparation method of the pH-responsive cigarette filter functional material of the present invention adopts the following steps:

[0041] 1) Fully swell polyvinyl alcohol 1788 in water, and then heat it to fully dissolve to obtain a polyvinyl alcohol solution, add sodium chloride to the polyvinyl alcohol solution to dissolve, and obtain a water phase; in the water phase, polyvinyl alcohol The mass fraction is 0.6%, and the mass fraction of sodium chloride is 7%;

[0042] Mix divinylbenzene, ethyl acrylate, and liquid paraffin evenly in a mass ratio of 30:70:150, then add initiator azobisisobutyronitrile (azobisisobutyronitrile accounts for the total amount of ethyl acrylate and divinylbenzene) 2% of the mass) mix uniformly to obtain the oil phase;

[0043] Add the water phase into a 250ml three-necked flask equipped with a stirrer, reflux condenser and thermometer, raise the temperature to 40°C, add the oil phase under stirring, the mass ratio of the ...

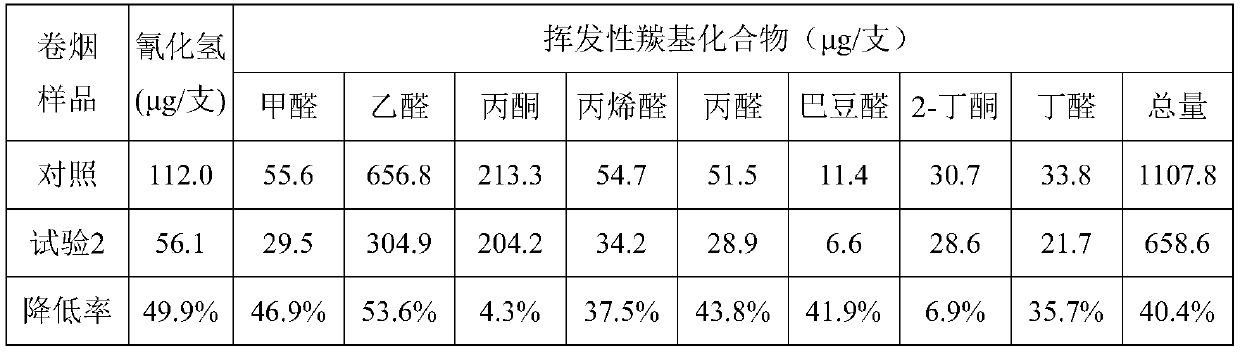

Embodiment 2

[0046] Example 2 of the preparation method of the pH-responsive cigarette filter functional material of the present invention adopts the following steps:

[0047] 1) Fully swell polyvinyl alcohol 1788 in water, and then heat it to fully dissolve to obtain a polyvinyl alcohol solution, add sodium chloride to the polyvinyl alcohol solution to dissolve, and obtain a water phase; in the water phase, polyvinyl alcohol The mass fraction is 1.2%, and the mass fraction of sodium chloride is 10%;

[0048] Mix divinylbenzene, ethyl methacrylate, liquid paraffin, and toluene in a mass ratio of 20:80:40:80, and then add the initiator azobisisobutyronitrile (azobisisobutyronitrile accounts for methacrylic acid 1% of the total mass of ethyl ester and divinylbenzene) mixed uniformly to obtain an oil phase;

[0049] Add the water phase into a 250ml three-necked flask equipped with a stirrer, a reflux condenser and a thermometer, raise the temperature to 40°C, add the oil phase under stirring...

Embodiment 3

[0052] Example 3 of the preparation method of the pH-responsive cigarette filter functional material of the present invention adopts the following steps:

[0053] 1) Fully swell polyvinyl alcohol 1788 in water, and then heat it to fully dissolve to obtain a polyvinyl alcohol solution, add sodium chloride to the polyvinyl alcohol solution to dissolve, and obtain a water phase; in the water phase, polyvinyl alcohol The mass fraction is 1.5%, and the mass fraction of sodium chloride is 10%;

[0054] Mix divinylbenzene, methyl methacrylate, and 120# gasoline in a mass ratio of 40:60:100, then add initiator azobisisobutyronitrile (azobisisobutyronitrile accounts for methyl methacrylate and 1.5% of the total mass of divinylbenzene) mixed uniformly to obtain an oil phase;

[0055] Add the water phase into a 250ml three-neck flask equipped with a stirrer, reflux condenser and thermometer, raise the temperature to 40°C, add the oil phase under stirring, the mass ratio of the oil phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com