Preparation method of magnetic nanometer particles with adjustable and controllable particle diameter

A technology of magnetic nanoparticles and particle size, applied in the direction of magnetism of inorganic materials, can solve the problems of uncontrollable decomposition rate of metal precursors, unfavorable promotion and application, and failure to achieve, and achieves good application prospects and high regulation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

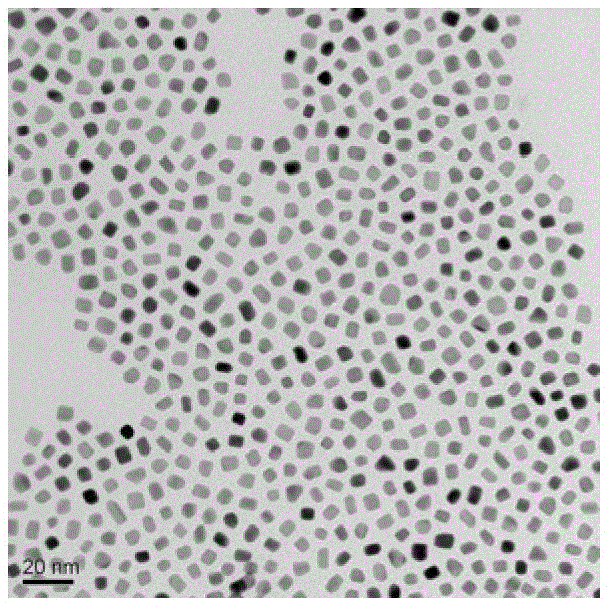

Embodiment 1

[0038]Mix 250ul carbonyl iron and 0.75ml oleylamine E1 in an Ar atmosphere, obtain a uniformly mixed viscous liquid under magnetic stirring, raise the temperature to 30°C, and keep it for 1h to obtain a viscous complex reaction mixture of carbonyl iron and oleylamine A1. At the same time, 198 mg of platinum acetylacetonate was dispersed in dibenzyl ether, 3.75 ml of oleic acid and 3 ml of oleylamine E2 were added, and the mixed solution B1 was obtained by ultrasonication for 10 min. Next, add the B1 solution to the A1 viscous liquid, raise the temperature to 250°C at a rate of 5°C / min under magnetic stirring, and reflux at this temperature for 1 hour. Remove heat source and cool to room temperature naturally. The whole process has been carried out under the protection of inert gas. The obtained product is centrifuged with ethanol at a speed of 6000 rpm or more for a centrifugation time of more than 10 minutes to obtain magnetic nano FePt particles, which are dispersed in non...

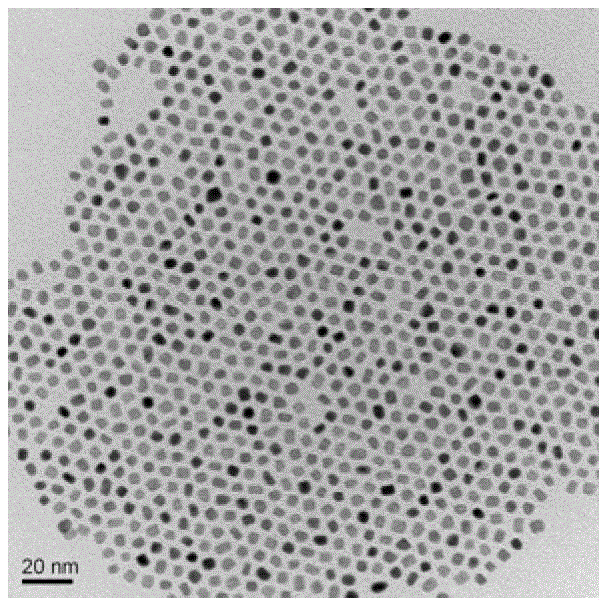

Embodiment 2

[0041] Mix 250ul carbonyl iron and 2.25ml oleylamine E1 in an Ar atmosphere, obtain a uniformly mixed viscous liquid under magnetic stirring, raise the temperature to 30°C, and keep it for 1h to obtain a viscous complex reaction of carbonyl iron and oleylamine Mix A2. At the same time, 198 mg of platinum acetylacetonate was dispersed in dibenzyl ether, 3.75 ml of oleic acid and 1.5 ml of oleylamine E2 were added, and the mixed solution B2 was obtained by ultrasonication for 10 min. Next, add the B2 solution into the A2 viscous liquid, raise the temperature to 250° C. at a rate of 5° C. / min under the condition of magnetic stirring, and reflux at this temperature for 1 hour. Remove heat source and cool to room temperature naturally. The whole process has been carried out under the protection of inert gas. The obtained product is centrifuged with ethanol at a speed of 6000 rpm or more for a centrifugation time of more than 10 minutes to obtain magnetic nano FePt particles, whic...

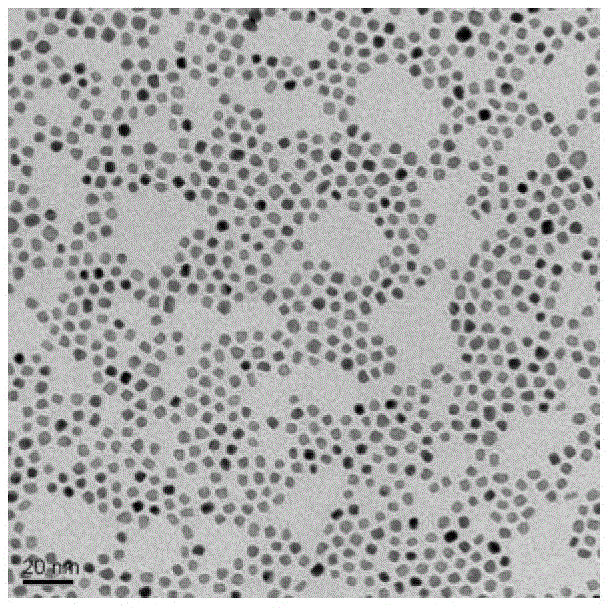

Embodiment 3

[0044] Mix 250ul carbonyl iron and 3ml oleylamine E1 in an Ar atmosphere, obtain a uniformly mixed viscous liquid under magnetic stirring, raise the temperature to 30°C, and keep it for 1h to obtain a viscous carbonyl iron and oleylamine complex reaction mixture A3. At the same time, 198 mg of platinum acetylacetonate was dispersed in dibenzyl ether, 3.75 ml of oleic acid and 0.75 ml of oleylamine E2 were added, and the mixed solution B3 was obtained by ultrasonication for 10 min. Next, add the B3 solution to the A3 viscous liquid, raise the temperature up to 250°C at a rate of 5°C / min under the condition of magnetic stirring, and reflux at this temperature for 1 hour. Remove heat source and cool to room temperature naturally. The whole process has been carried out under the protection of inert gas. The obtained product is centrifuged with ethanol at a speed of 6000 rpm or more for a centrifugation time of more than 10 minutes to obtain magnetic nano FePt particles, which ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com