Draining and oxygen adding device for full-automatic heater

A fully automatic heater technology, applied in chemical instruments and methods, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of unit adjustment performance influence, reporting, and no hydrophobic and oxygen treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

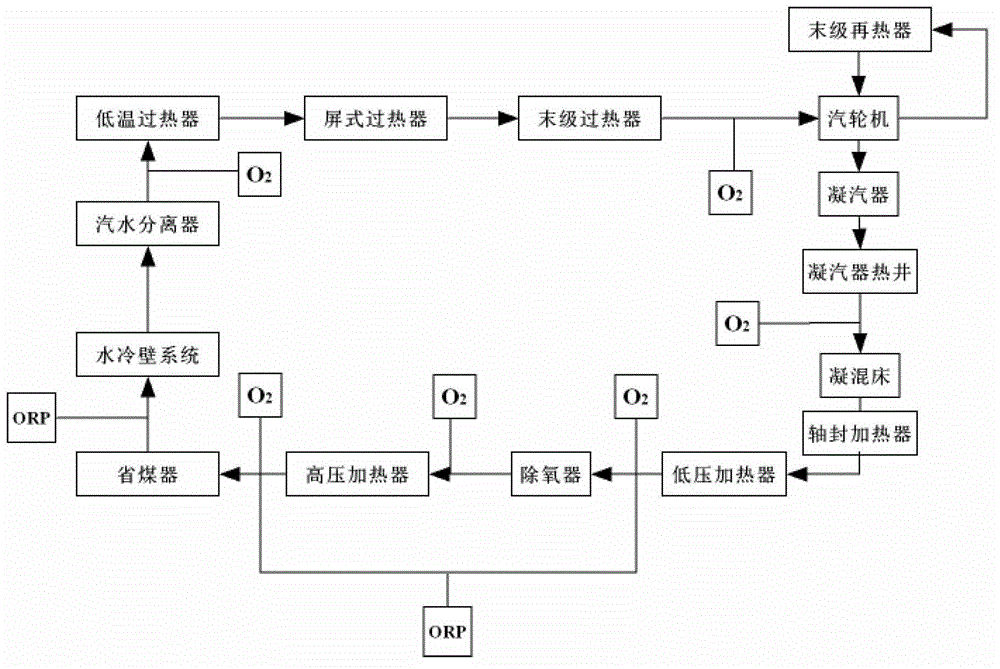

[0056] Taking the existing boiler water vapor circulation system as an example, the fully automatic heater hydrophobic oxygenation device and method of the present invention will be further described:

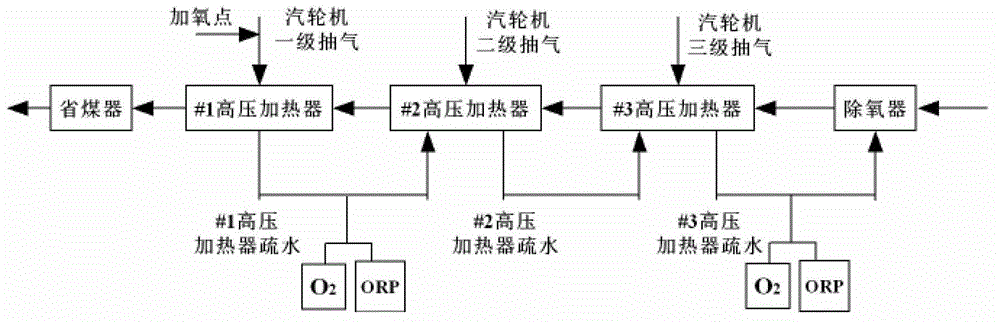

[0057] Such as figure 2 As shown, the heater of the present invention is three high-pressure heaters whose tube side is connected in series between the water outlet of the deaerator and the water inlet of the economizer; the shell sides of the three high-pressure heaters are also connected in series in sequence, respectively #1 Heaters, #2 High Pressure Heater and #3 High Pressure Heater. There are three stages of pumping at the outlet of the steam turbine to enter the shell side of #1 high-pressure heater, #2 high-pressure heater and #3 high-pressure heater to turn into hydrophobic, and the hydrophobic in the shell side of the high-pressure heater flows into the deaerator step by step, and then It enters the tube side of the high pressure heater through the deaerator. Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com