Nonionic hydrophilic monomer for synthesis of waterborne polyurethane and synthetic method thereof

A non-ionic hydrophilic, water-based polyurethane technology, applied in the polymer field, to facilitate large-scale industrial production, avoid emulsion breaking, and easily obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

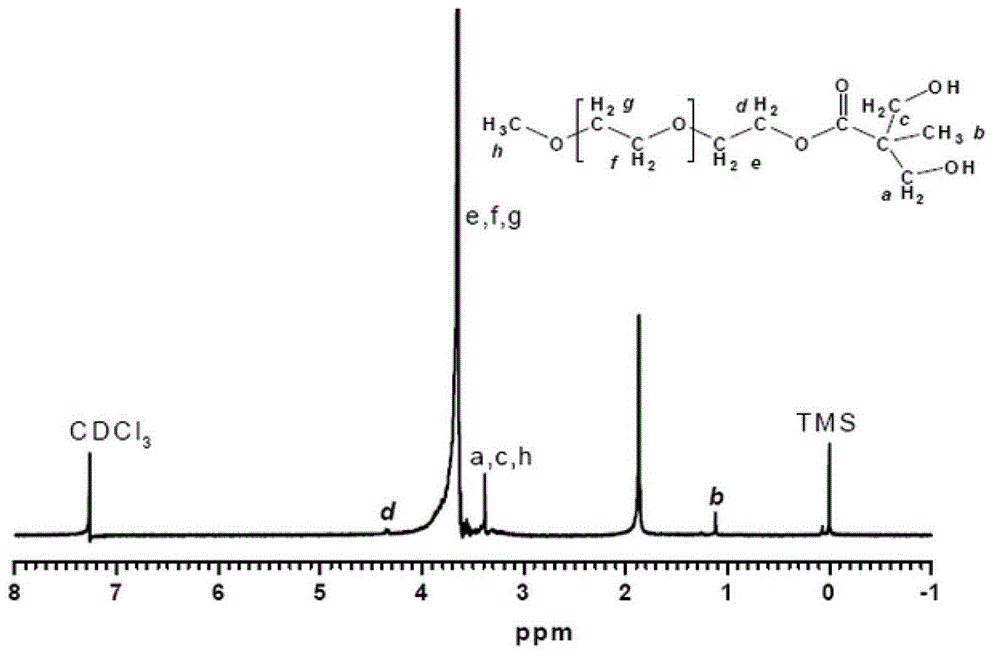

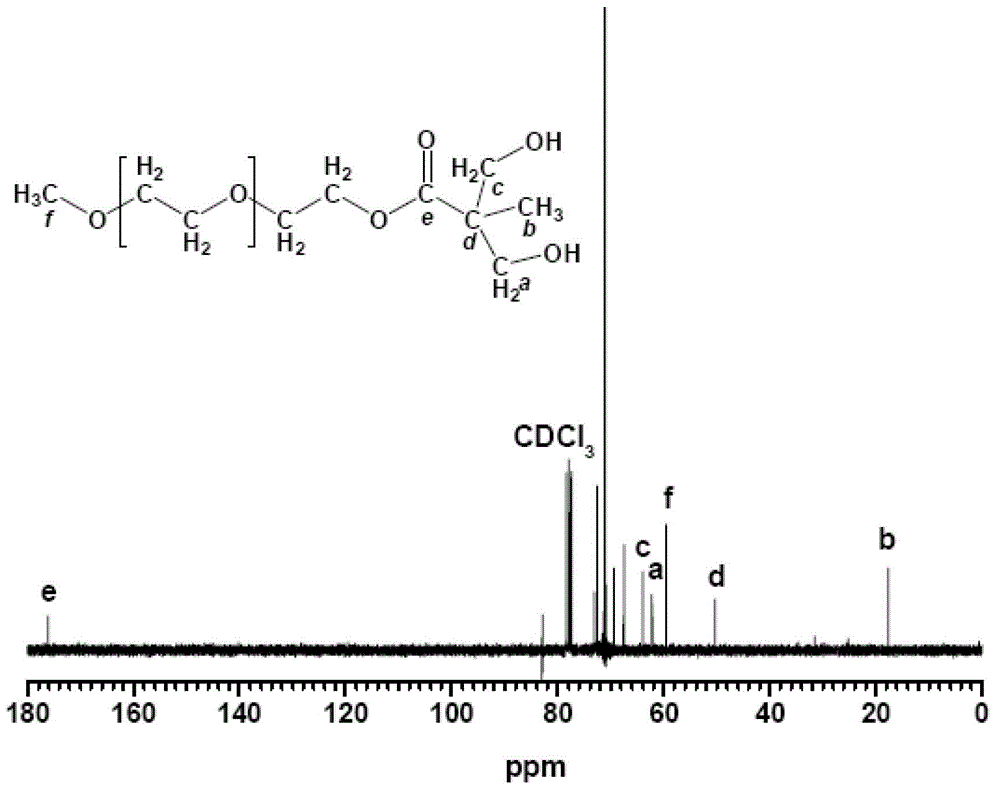

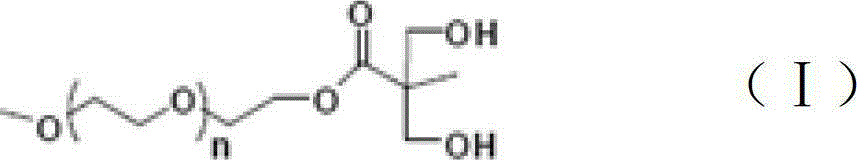

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 1mol of 2,2-dimethylolpropionic acid in 500ml of acetone, and dissolve 0.1mol of p-toluenesulfonic acid and 1.2mol of 2,2-dimethoxypropane in acetone. The above solution was put into a three-necked flask, filled with nitrogen for 30 minutes, and reacted at 60° C. for 12 hours. The reaction product was filtered out through a silica gel column, dried under vacuum for 12 hours, and the solvent was fully evaporated to obtain 170 g of the product.

[0023] Add 1700g of N,N'-dicyclohexylcarbodiimide to a three-necked flask, dissolve 170g of the above product in it, then add 0.1mol of 4-dimethylaminopyridine, and then add 1500g of polyethylene glycol monomethanol with a molecular weight of 1000 Ether, the esterification reaction is carried out at 120°C. After reacting for 6 hours, the product was filtered out through a silica gel column and dried for 12 hours to obtain 1660 g of an esterified product.

[0024] Add 840g of 37% hydrochloric acid and 840g of methanol i...

Embodiment 2

[0027] Dissolve 1.2mol of 2,2-dimethylolpropionic acid in 500ml of acetone, and dissolve 0.12mol of p-toluenesulfonic acid and 2mol of 2,2-dimethoxypropane in acetone. The above solution was put into a three-necked flask, filled with nitrogen for 30 minutes, and reacted at 60° C. for 10 hours. The reaction product was filtered out through a silica gel column, dried under vacuum for 12 hours, and the solvent was fully evaporated to obtain 204 g of the product.

[0028] Add 2000g of N,N'-dicyclohexylcarbodiimide to a three-necked flask, dissolve 204g of the above product in it, then add 0.12mol of 4-dimethylaminopyridine, and then add 1800g of polyethylene glycol monomethyl ether with a molecular weight of 1000 , The esterification reaction was carried out at 130°C. After reacting for 6 hours, the product was filtered out through a silica gel column and dried for 12 hours to obtain 2000 g of the esterified product.

[0029] Add 1000g of 37% concentrated hydrochloric acid and 1...

Embodiment 3

[0031] Dissolve 2mol 2,2-dimethylolpropionic acid in 1000ml dimethylformamide, and dissolve 0.2mol p-toluenesulfonic acid and 3mol 2,2-dimethoxypropane in dimethylformamide amides. The above solution was put into a three-necked flask, filled with nitrogen for 30 minutes, and reacted at 60° C. for 10 hours. The reaction product was filtered out through a silica gel column, dried under vacuum for 12 hours, and the solvent was fully evaporated to obtain 337 g of the product.

[0032] Add 3200g of N,N'-dicyclohexylcarbodiimide to a three-necked flask, dissolve 337g of the above product in it, then add 0.2mol of 4-dimethylaminopyridine, and then add 2700g of polyethylene glycol monomethyl ether with a molecular weight of 1000 , The esterification reaction was carried out at 130°C. After reacting for 6 hours, the product was filtered out through a silica gel column and dried for 12 hours to obtain 3000 g of an esterified product.

[0033] Add 2000g of 37% concentrated hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com