Simulation method of texture evolvement of heat affected zone in welding process

A technology of heat-affected zone and welding process, applied in heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problem that the structure, size and distribution cannot be dynamically reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

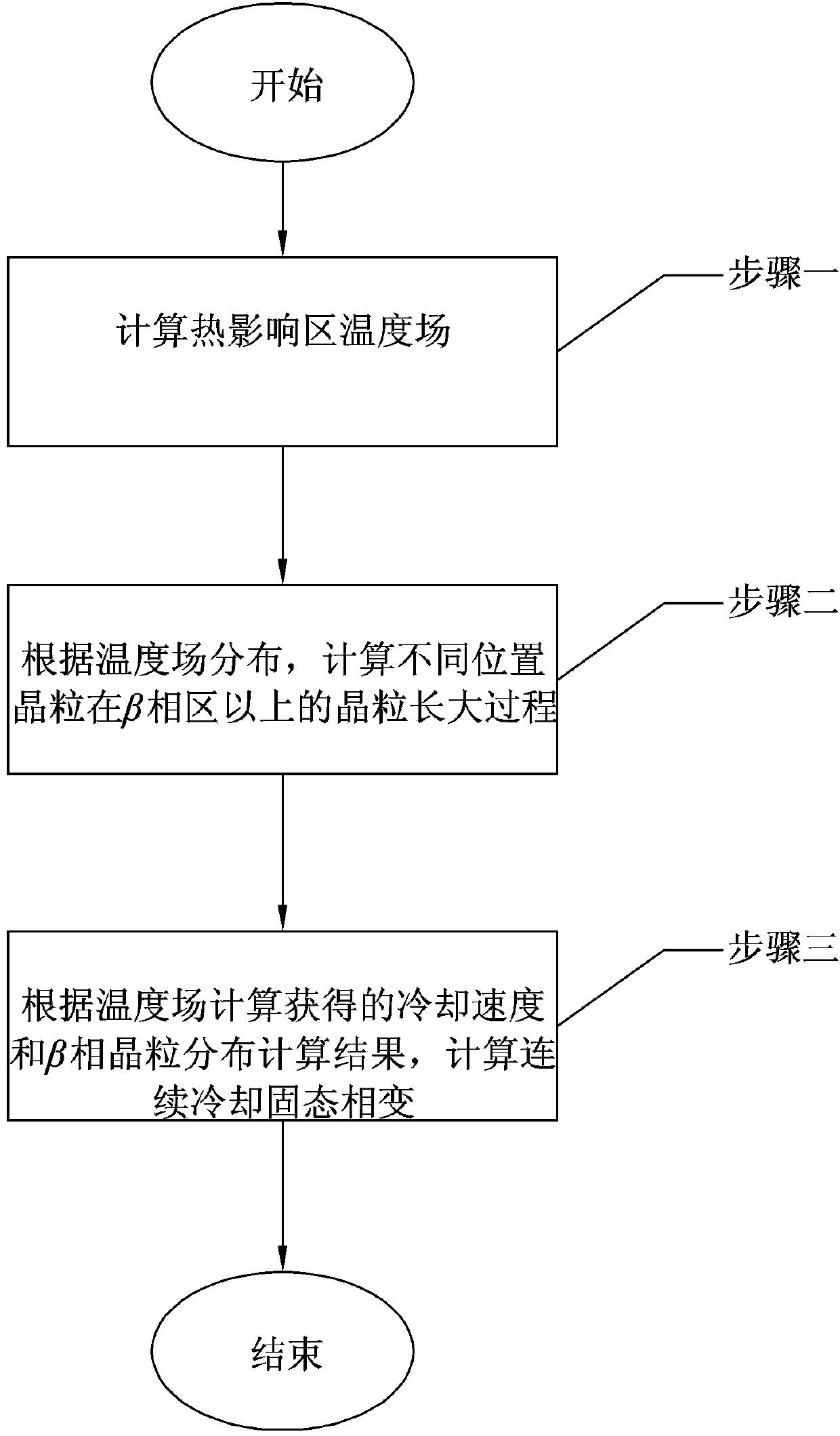

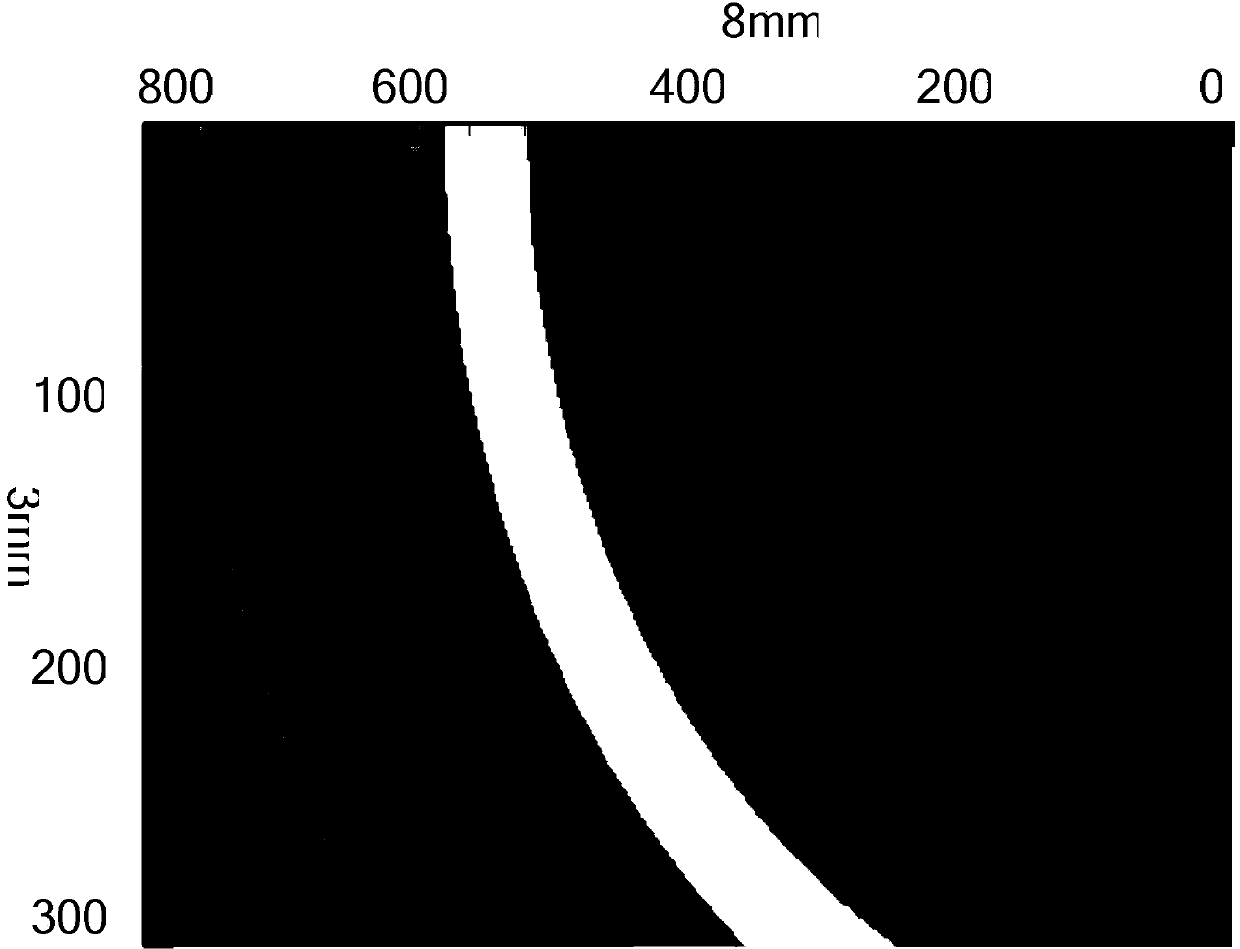

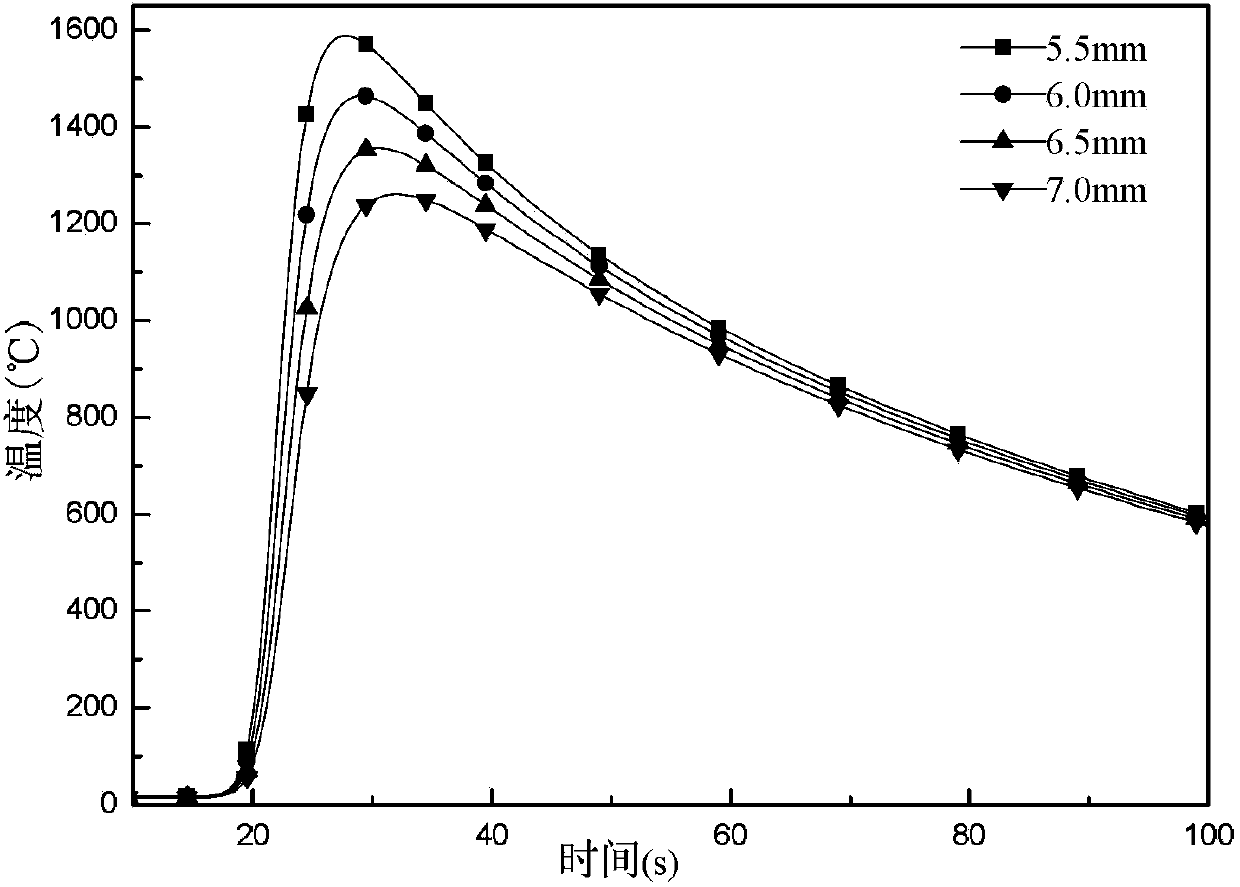

[0088] Specific implementation mode 1: Combination Figure 1 ~ Figure 5 To illustrate this embodiment, the method for simulating the evolution of the structure of the heat-affected zone of the welding process of the present invention is realized through the following steps:

[0089] Step 1: Calculate the temperature field of the heat affected zone:

[0090] By solving the thermal differential equation, and attaching the initial conditions and heat transfer boundary conditions, the temperature field distribution of the welding process is obtained:

[0091] Formula one: ρc ∂ T ∂ t = ∂ ∂ x ( λ ∂ T ∂ t ) + ∂ ∂ y ( λ ∂ T ∂ t ) + ∂ ∂ z ( λ ∂ T ∂ z ) + Q ‾

[0092] Among them, T is the thermodynamic temperature, ρ is the density of the material, λ is the thermal conductivity of the material, c is the specific heat of the material, Is the intensity of the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com