Method for preparing micro-solution storage and multi-phase heterogenous microparticles

A memory and dissimilarity technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problem of inability to form dual-phase or multi-phase microparticles, non-uniform microparticle size, and difficulty in achieving monodisperse characteristics and other problems, to achieve the effect of adjustable quantity, uniform particle size and controllable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

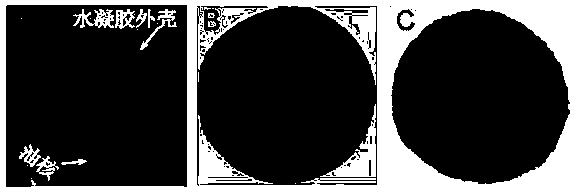

[0027] Preparation of hydrogel microsolution reservoir containing single oil core content and two-phase and two-sided heterotropic microparticles:

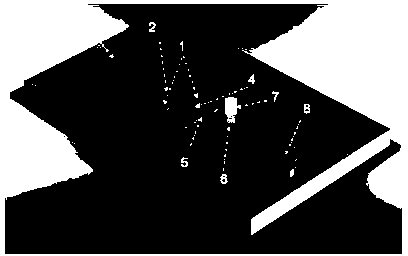

[0028] The schematic diagram of the microfluidic chip used in the preparation is as follows: figure 1 shown. Firstly, the microfluidic chip with channels on the upper layer is prepared by soft lithography technology, and then it is irreversibly sealed with the lower substrate by oxygen plasma.

[0029] The stable double emulsion micro-droplets can be formed by hydrophobizing and hydrophilizing the surface of the channel. Then an external peristaltic pump is used to drive different solutions. The isopropylacrylamide monomer solution enters the water phase microchannel 2, the dispersed oil core phase (mineral oil) enters the dispersed oil core phase microchannel 1, and the continuous oil phase (FC-40) enters the continuous oil phase microchannel 3, and its flow rate is adjusted to 0.9 μL / min, 0.01 μL / min, and 3.0 μL / min respective...

Embodiment 2

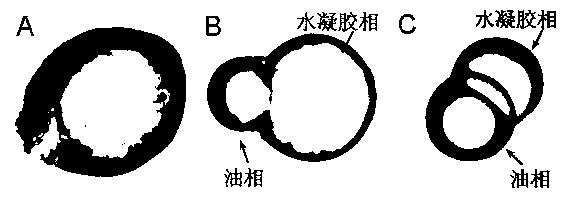

[0032] Hydrogel microsolution storage of complex oil core content and preparation of heterogeneous microparticles with multi-phase and multi-facets:

[0033] Preparation of chips used and control of various fluids such as figure 1As shown, when the flow rates of isopropylacrylamide solution, mineral oil and FC-40 are 0.9 μL / min, 0.03 μL / min, and 3.0 μL / min, two oils can be included in the formation of double emulsion microdroplets. core, and then polymerized into a hydrogel microsolution reservoir containing two oil core contents, when the flow rate of mineral oil was adjusted to 0.05 μL / min, a microsolution reservoir containing three oil core contents could be formed, like Figure 4 Shown are the formed microsolution reservoirs with two (A to C) and three (D to F) oil core inclusions and their oil core release upon addition of water. Natural dehydration of multiple inclusions at room temperature will form two-phase three-sided heterogeneous microparticles (such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com