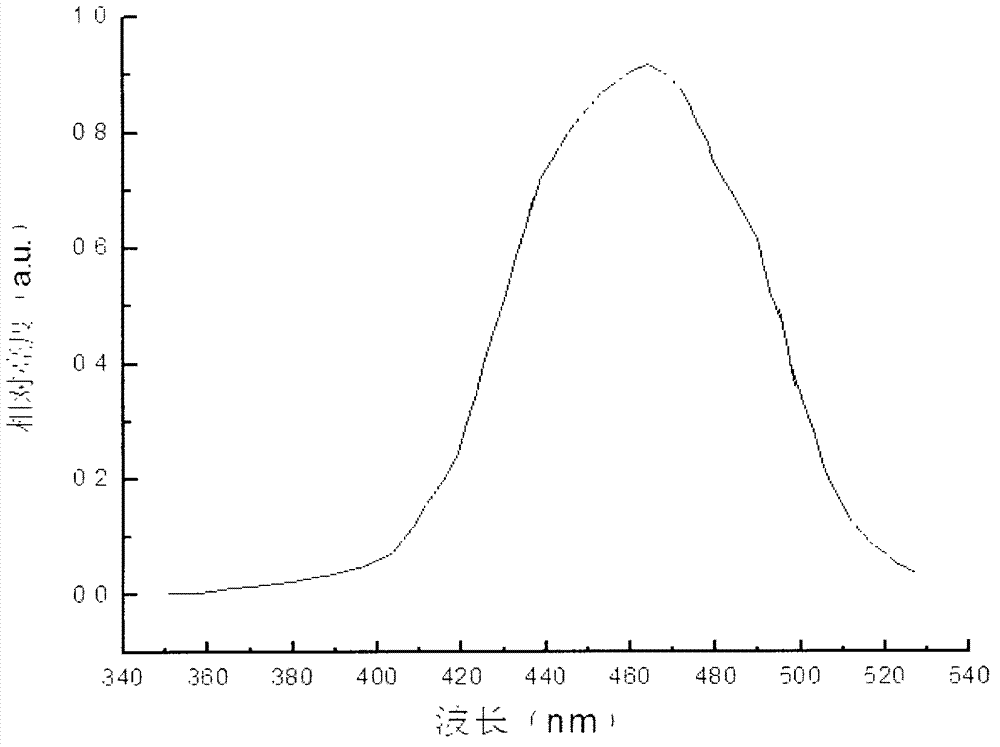

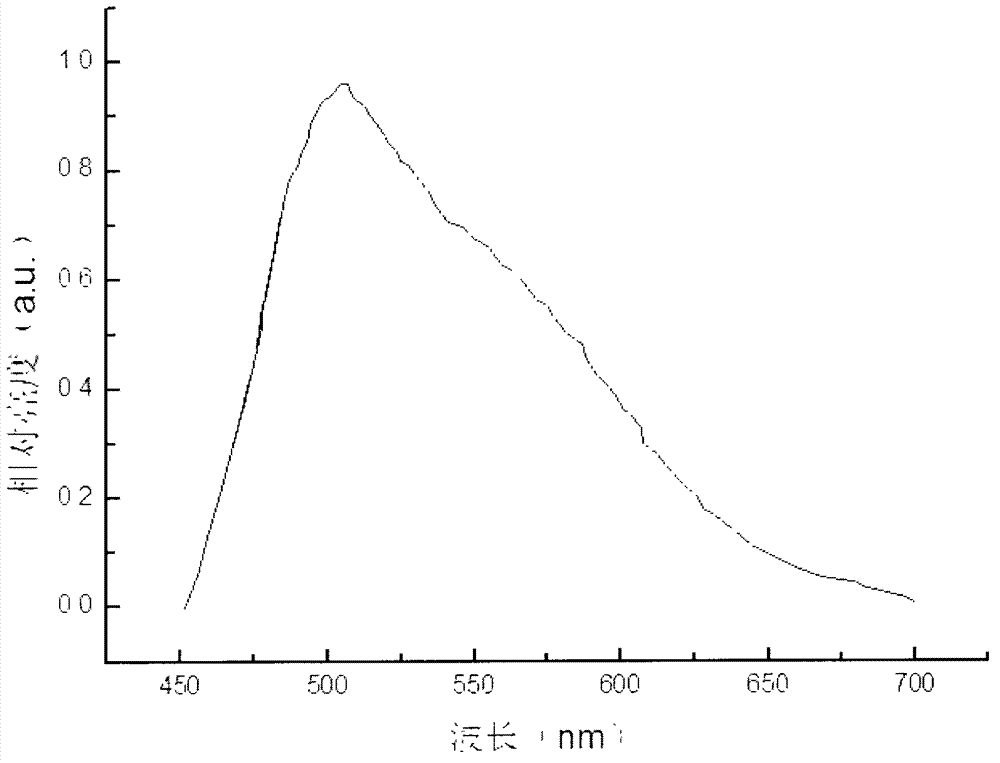

Blue light excited green fluorescent powder for white light light-emitting diode (LED) and preparing method thereof

A green fluorescent powder and blue light excitation technology, applied in the field of green fluorescent powder, can solve problems such as poor color rendering and weak luminous intensity, and achieve the effects of improved luminous brightness and intensity, simple operation, and high commercial use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: take by weighing Sc 2 o 3 7.935g, CaCO 3 5.405g, BaCO 3 21.680g, CeO 2 1.720g, H 2 SiO 3 9.275g, H 3 BO 3 0.092g, LiF0.005g, the above raw materials are all analytically pure, add deionized water to the above raw materials for wet mixing, then ball mill for 10h, and then dry, at 1200 ° C, H 2 and N 2 Calcined for 3h under the mixed gas reducing condition, where H 2 Accounting for 5% of the total volume of the mixed gas, the molecular composition is Ca 1.080 Ba 2.192 sc 2.302 Si 2.378 o 11.356 : Ce 0.002 sample.

Embodiment 2

[0019] Example 2: The weighed raw materials, flux content and manufacturing method are the same as in Example 1, the difference is that the calcination temperature is 1000°C, and the obtained molecular composition is Ca 1.080 Ba 2.192 sc 2.302 Si 2.378 o 11.356 : Ce 0.002 sample.

Embodiment 3

[0020] Example 3: The weighed raw materials, flux content and manufacturing method are the same as in Example 1, the difference is that the calcination temperature is 1300°C, and the molecular composition is Ca 1.080 Ba 2.192 sc 2.302 Si 2.378 o 11.356 : Ce 0.002 sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com