White-light LED (Light Emitting Diode) light source

A technology of LED light source and LED chip, which is applied in the field of white LED light source, can solve the problems such as the decrease of light efficiency of white light LED light source, and achieve the effects of reducing light loss, avoiding reabsorption, and improving color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

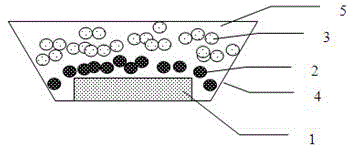

[0039] Gallium Nitride blue light chips with main emission peaks at 445-450nm are selected, and the composition of the yellow-green phosphor used is Y 2.95 al 5 o 12 : Ce 0.05 , the main emission peak is 568.4nm, and the red phosphor used is Ca 0.85 Sr 0.1 AlSiN 3 :Eu 0.05 , the emission wavelength is 643nm, the mass ratio of the two phosphors is 90.3:9.7, the red phosphor and the yellow-green phosphor are respectively dispersed in the silica gel to make the red phosphor glue and the yellow-green phosphor glue, first red The phosphor powder glue is coated on the blue LED chip, and after it is dried, the yellow-green phosphor powder glue is coated on it. Its cross-sectional structure diagram is shown in figure 2 shown. The white light optical data of this light source are shown in Table 1.

[0040] Such as figure 2 As shown, the blue light emitted by the blue LED chip 1 passes through the encapsulation glue 5, part of which first excites the red light emitted by the...

Embodiment 2

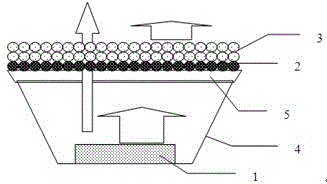

[0042] Gallium Nitride blue light chips with main emission peaks at 452-457nm are selected, and the composition of the yellow-green phosphor used is Y 2.95 al 5 o 12 : Ce 0.05 , the main emission peak is 568.4nm, and the composition of the red phosphor is Ca 0.85 Sr 0.1 AlSiN 3 :Eu 0.05 , the emission wavelength is 643nm, and the mass ratio of these two phosphors is 90.3:9.7. First, evenly coat the red phosphor on the transparent layer made of polycarbonate (PC), then coat the yellow-green phosphor on the surface of the red phosphor layer, and place the transparent layer with the phosphor fixed in the bowl Above the blue LED chip inside the cup. Its cross-sectional structure diagram is shown in image 3 shown. The white light optical data of this light source are shown in Table 1.

[0043] Such as image 3 As shown, part of the blue light emitted by the blue LED chip 1 first excites the red light emitted by the red phosphor powder 2 on the transparent layer 4, and t...

Embodiment 3

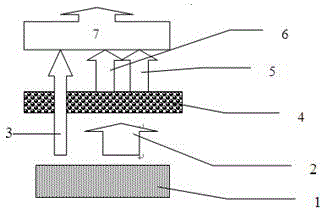

[0045] Gallium Nitride blue light chips with main emission peaks at 450-455nm are selected, and the composition of the yellow-green phosphor used is Y 2.95 al 5 o 12 : Ce 0.05 , the main emission peak is 568.4nm, and the composition of the red phosphor is Ca 0.85 Sr 0.1 AlSiN 3 :Eu 0.05 , the emission wavelength is 643nm, and the total ratio of these two phosphors is 91.6:8.4. Mix red fluorescent powder and green fluorescent powder with polyethylene (PE) to make red fluorescent powder cake and yellow-green fluorescent powder cake, and then fix the two fluorescent powder cakes together according to the red on the bottom and yellow-green on the top, and put them in the bowl. Above the LED chip, the schematic diagram of its cross-sectional structure is as follows Figure 4 shown. The white light optical data of this light source are shown in Table 1.

[0046] Such as Figure 4 As shown, part of the blue light emitted by the blue LED chip 1 first excites the red phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com