Graphene oxide/polythiophene derivative composite material as well as preparation method and application thereof

A technology of polythiophene derivatives and thiophene derivatives is applied in the field of electrochemical materials, which can solve the problems of easy damage to the skeleton structure and capacity decay, and achieve the effects of high conductivity, improved discharge performance, and improved electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

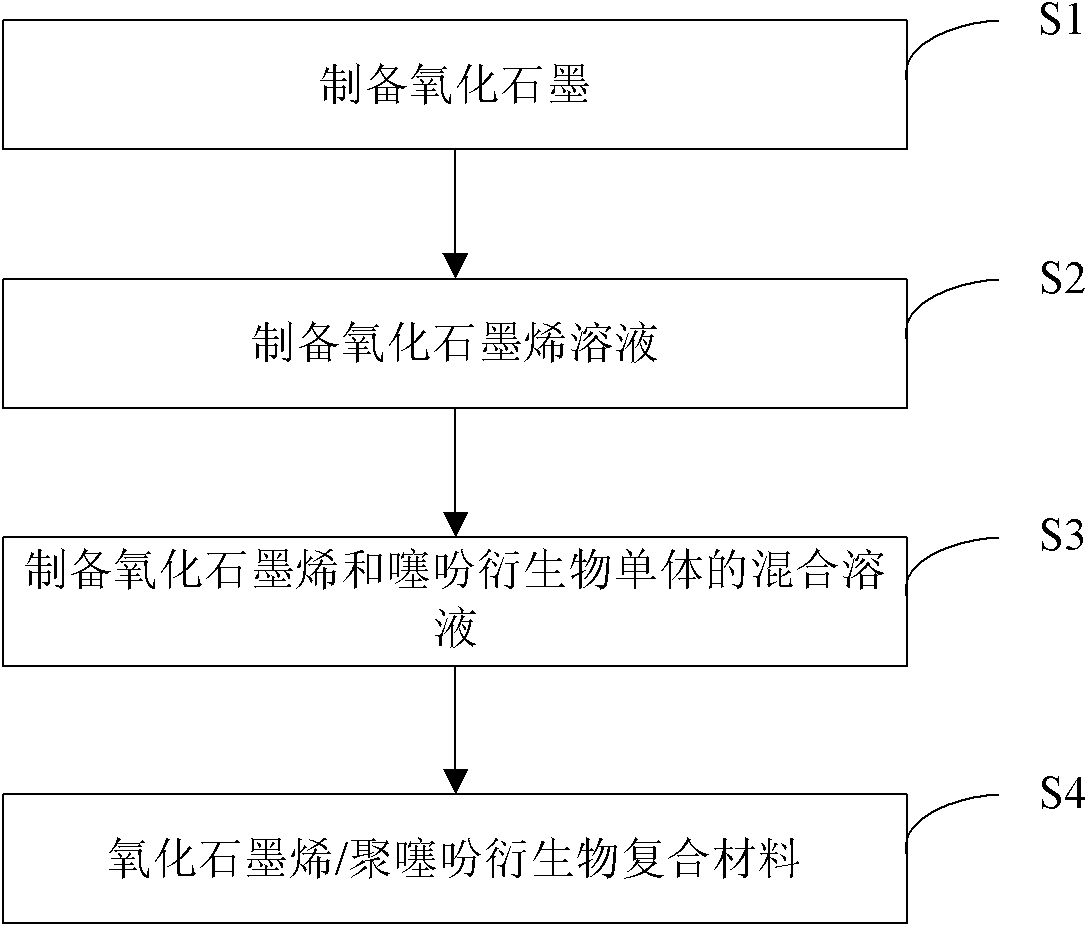

[0016] A kind of preparation method of graphene oxide / polythiophene derivative composite material, such as figure 1 shown, including the following steps:

[0017] Step S1, add 500 mesh graphite powder into concentrated sulfuric acid at 0°C, then add potassium permanganate (mass ratio of graphite powder to potassium permanganate is 1:3), and keep stirring at 0-10°C for 2 hours , then stirred in a water bath at room temperature for 24h, then slowly added deionized water, then added a hydrogen peroxide solution with a concentration of 30wt%, and then carried out suction filtration, washing, suction filtration and drying to obtain graphite oxide; wherein, the washing process The washing solution adopts hydrochloric acid with a mass percentage concentration of 10%;

[0018] Step S2, adding graphite oxide into water, and ultrasonically dispersing to obtain a monolithic graphene oxide solution;

[0019] Step S3, adding a thiophene derivative monomer (EDOT) to the graphene oxide sol...

Embodiment 1

[0025] (1) Add 0.5g of 500-mesh graphite powder with a purity of 99.5% to 0°C and 11.5mL of concentrated sulfuric acid, then add 1.5g of potassium permanganate, keep the temperature of the mixture at 0°C, stir for 2 hours, and then place it in a water bath at room temperature After stirring for 24 hours, slowly add 46 mL of deionized water under ice-bath conditions; after 15 minutes, add 140 mL of deionized water, and then add 2.5 mL of 30 wt % hydrogen peroxide solution, after which the color of the mixture turns bright yellow, and suction filtration, and then Washing with 250ml of 10% hydrochloric acid, suction filtration, and vacuum drying at 60°C for 48 hours to obtain graphite oxide;

[0026] (2) disperse the graphite oxide that the quality obtained in (1) is 0.5g in 100ml water, carry out ultrasonic dispersion 2h and obtain the graphene oxide solution of monolithic layer;

[0027] (3) Add 0.25 g of thiophene derivative (EDOT) monomer to the graphene oxide solution obtain...

Embodiment 2

[0030] (1) is consistent with (1) in embodiment 1;

[0031] 2) Dispersing graphite oxide with a quality of 0.25 g obtained in (1) in 100 ml of water, and ultrasonically dispersing for 1 h to obtain a monolithic graphene oxide solution;

[0032] (3) Add 0.5 g of thiophene derivative (EDOT) monomer to the graphene oxide solution obtained in (2), and ultrasonically disperse for 1 h to obtain a mixed solution;

[0033] (4) Slowly add hydrochloric acid dropwise in (3) mixed solution, make pH value be 2, then slowly add 1.4g ammonium persulfate [(NH 4 ) 2 S 2 o 8 ] and 2.4 g Fe 2 (SO 4 ) 3 50ml of the mixed solution was stirred and reacted at room temperature for 20h, washed with water, and filtered to obtain a graphene oxide / polythiophene derivative composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com