Waterborne polyurethane resin for shoe material ink

A water-based polyurethane and ink technology, which is applied in the resin field of water-based polyurethane shoe material ink, can solve the problems of low solid content, low printing efficiency, and inability to use low-polarity materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with embodiment.

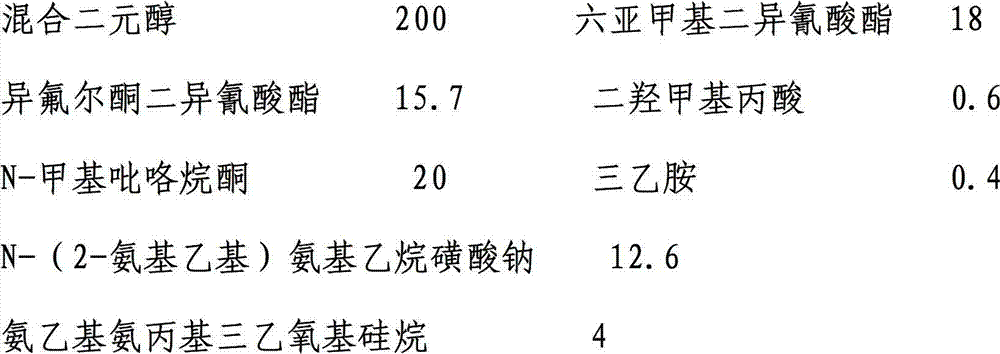

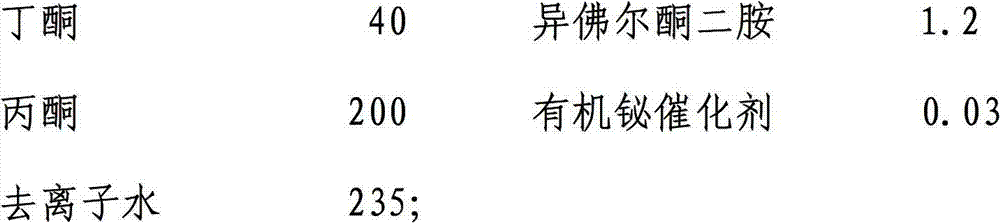

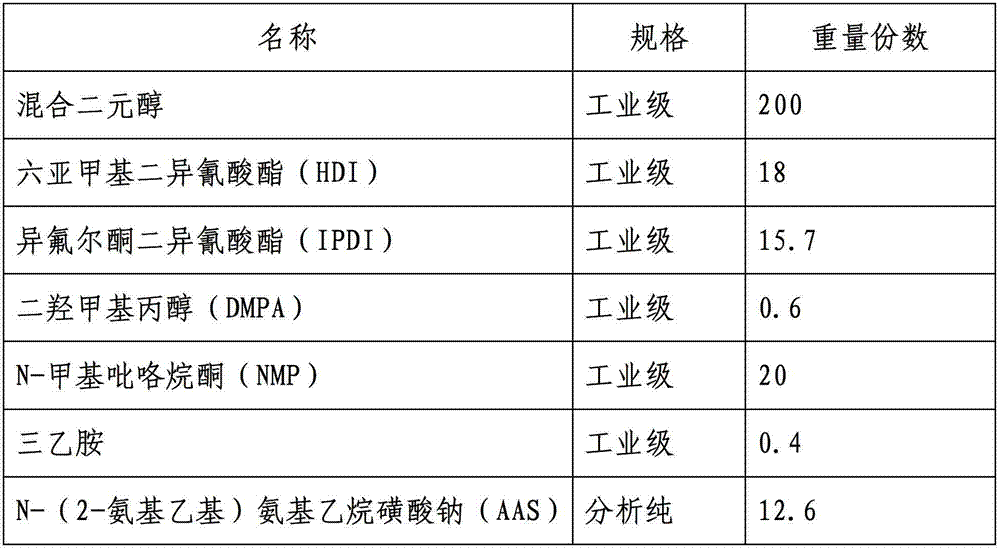

[0042] A kind of waterborne polyurethane resin that shoe material printing ink is used, the parts by weight of its formula:

[0043]

[0044]

[0045] The mixed diol is uniformly prepared by mixing adipic acid polyester diol, polycarbonate diol and dimer polyester diol, and the ratio of parts by weight is:

[0046] Diacid polyester diol 5 Polycarbonate diol 2

[0047] Dimer polyester diol 3.

[0048] A kind of manufacture method of the waterborne polyurethane resin that ink of shoe material is used, according to following method step: take raw material in proportion;

[0049] (1) Add mixed dibasic alcohol, isophorone diisocyanate, hexamethylene diisocyanate, urge organic bismuth catalyst, methyl ethyl ketone in the reaction kettle that agitator is housed, thermometer, condenser, heat up slowly 80- 90°C, reaction time 2 hours;

[0050] (2) Add dimethylolpropionic acid dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com