Method for preparing cadmium sulfide film by using chemical bath deposition method

A chemical water bath and cadmium sulfide technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of low heating efficiency, affecting the uniformity and compactness of the film, and affecting the appearance, so as to improve the uniformity and compactness, improve the quality of film formation, and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Cleaning the substrate: clean the substrate, then blow dry or dry it;

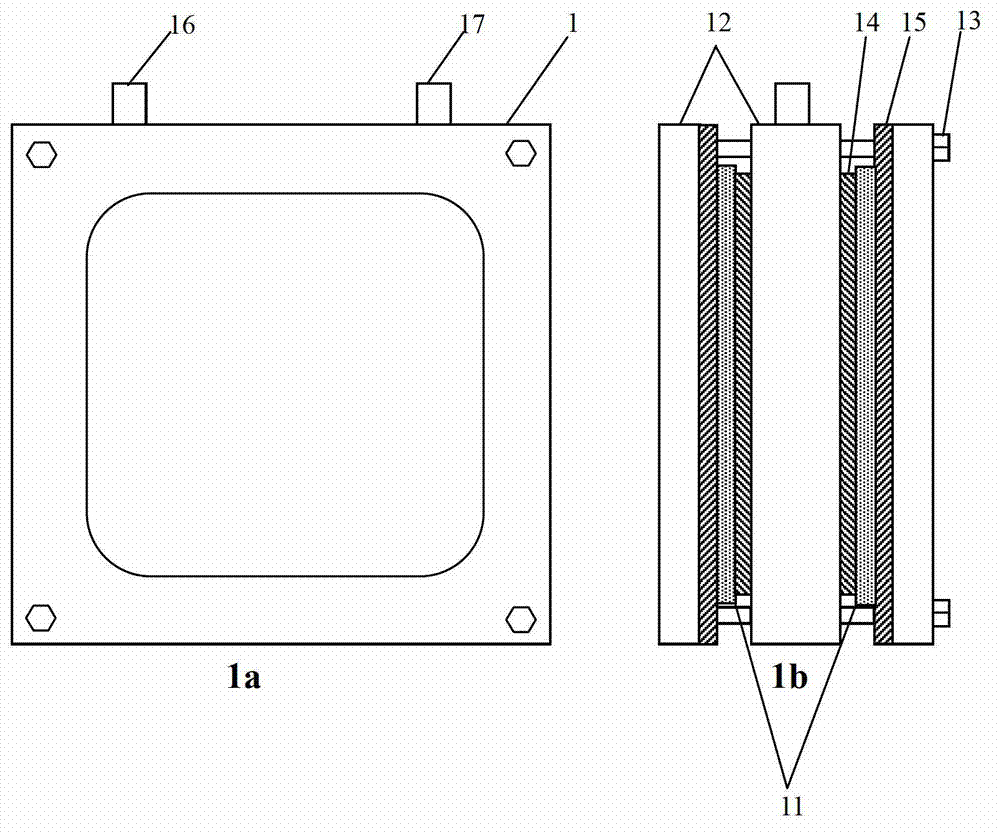

[0021] (2) Install the substrate: place the substrate in a special fixture and clamp it, and use a sealing ring and a rubber ring between the substrate and the fixture to keep the substrate evenly stressed and well sealed. constitute a reaction vessel;

[0022] (3) Configuration solution: Mix cadmium sulfate, ammonia water, ammonium chloride, thiourea, and deionized water in a certain proportion to make a reaction solution, so that Cd in the reaction solution is 2+ Concentration is 2mM, ammonia concentration is 0.3M, NH 4 + The concentration is 30 mM, and the concentration of thiourea is 40 mM, and then mixed into the reaction vessel;

[0023] (4) Reaction deposition: place the reaction vessel containing the reaction solution in a constant temperature water bath container, heat the reaction solution to 80°C, and the reaction time is 30min.

[0024] (5) Subsequent treatment: remove the substr...

Embodiment 2

[0027] (1) Cleaning the substrate: the same as in Example 1.

[0028] (2) Mounting substrate: the same as in Example 1.

[0029] (3) Configuration solution: Mix cadmium sulfate, ammonia water, ammonium sulfate, thiourea, and deionized water in a certain proportion to make a reaction solution, so that Cd in the reaction solution is 2+ Concentration is 4mM, ammonia concentration is 0.5M, NH 4 + The concentration was 50 mM, and the concentration of thiourea was 80 mM, and then added to the reaction vessel.

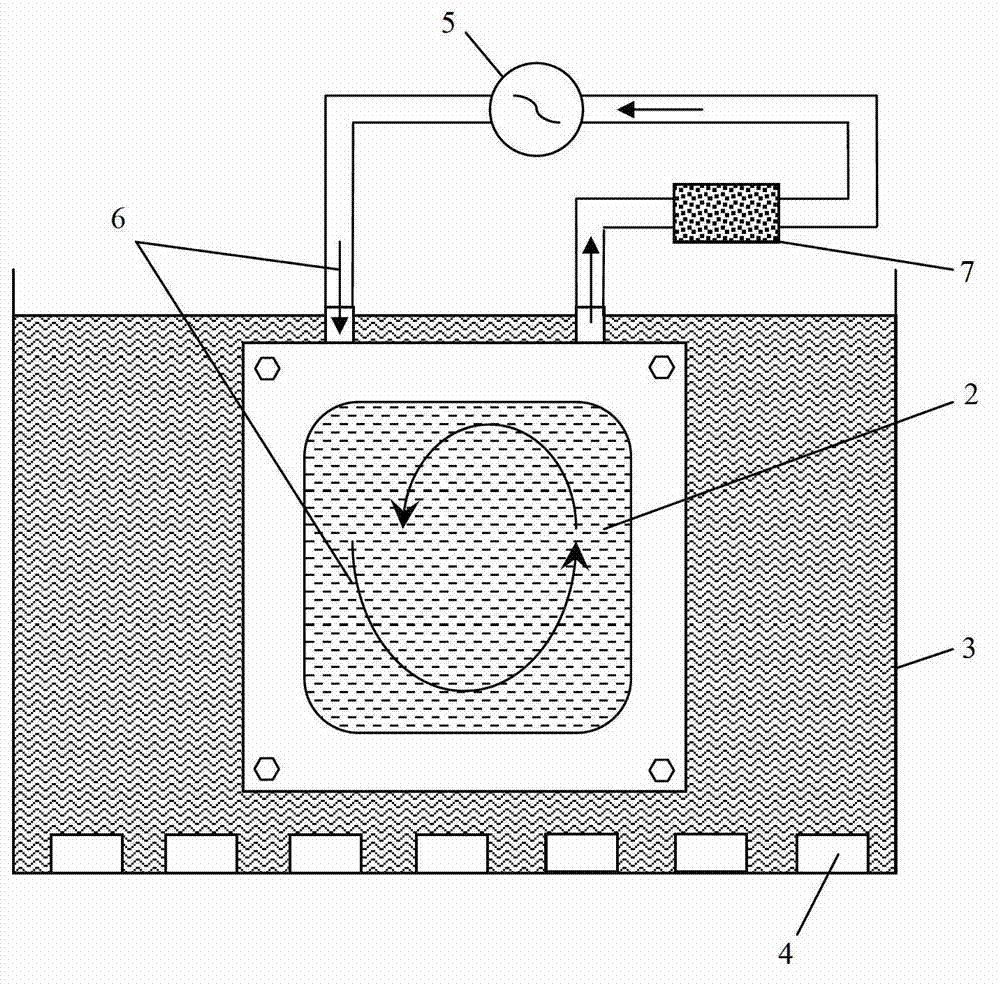

[0030] (4) Reaction deposition: place the reaction container containing the reaction solution in a constant temperature water bath container, heat the reaction solution to 70°C, and apply 20-50KHz ultrasonic wave to assist deposition during the reaction process, and the reaction time is 15min.

[0031] (5) Subsequent processing: the same as in Example 1.

Embodiment 3

[0033] (1) Cleaning the substrate: the same as in Example 1.

[0034] (2) Mounting substrate: the same as in Example 1.

[0035] (3) Configuration solution: Mix cadmium chloride, ammonia water, ammonium chloride, thiourea, and deionized water in a certain proportion to make a reaction solution, so that Cd in the reaction solution 2+ Concentration is 1.5mM, ammonia concentration is 0.8M, NH 4 + The concentration was 80 mM, and the concentration of thiourea was 20 mM, and then added to the reaction vessel.

[0036] (4) Reaction deposition: place the reaction vessel containing the reaction solution in a constant temperature water bath container, heat the reaction solution to 60°C, and apply 20-50KHz ultrasonic waves to assist deposition during the reaction process, and at the same time add a water pump to connect the water injection port and the fixture of the fixture. The water outlet makes the reaction solution circulate continuously in the reaction vessel to assist depositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com