MEMS (micro-electrochemical systems) accelerometer and production method thereof

A technology of an accelerometer and a manufacturing method, which is applied in the direction of measuring acceleration, velocity/acceleration/shock measurement, and manufacturing microstructure devices, etc., can solve the problem of inability to provide mechanical strength protection structures, insufficient shock resistance of accelerometers, and difficulty in sensitivity of non-sensitive axes. Inhibition and other problems, to achieve the effect of improving yield, low packaging equipment requirements, and small gas damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

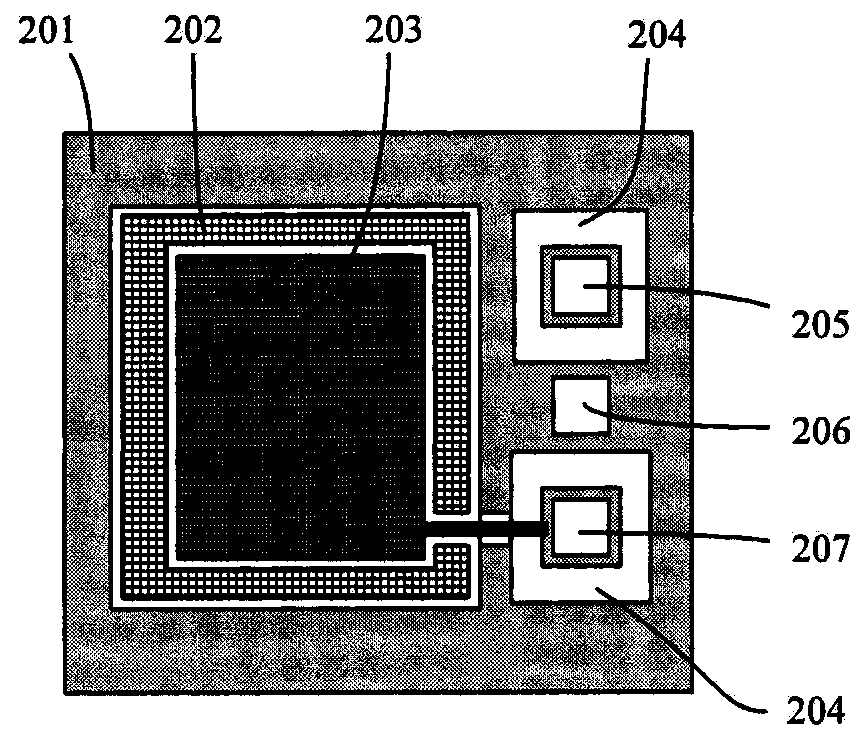

[0039] According to the working principle of capacitance detection, the MEMS high-precision accelerometer adopts a glass-silicon-glass three-layer structure: the metal electrode of the first glass layer forms the first capacitance with the upper surface of the mass block, and the metal electrode of the second glass layer forms the second capacitance with the lower surface of the mass block. Two capacitors; under the action of acceleration perpendicular to the direction of the mass block, the mass block will shift, causing changes in the upper and lower capacitances. Acceleration can be measured by detecting changes in capacitance.

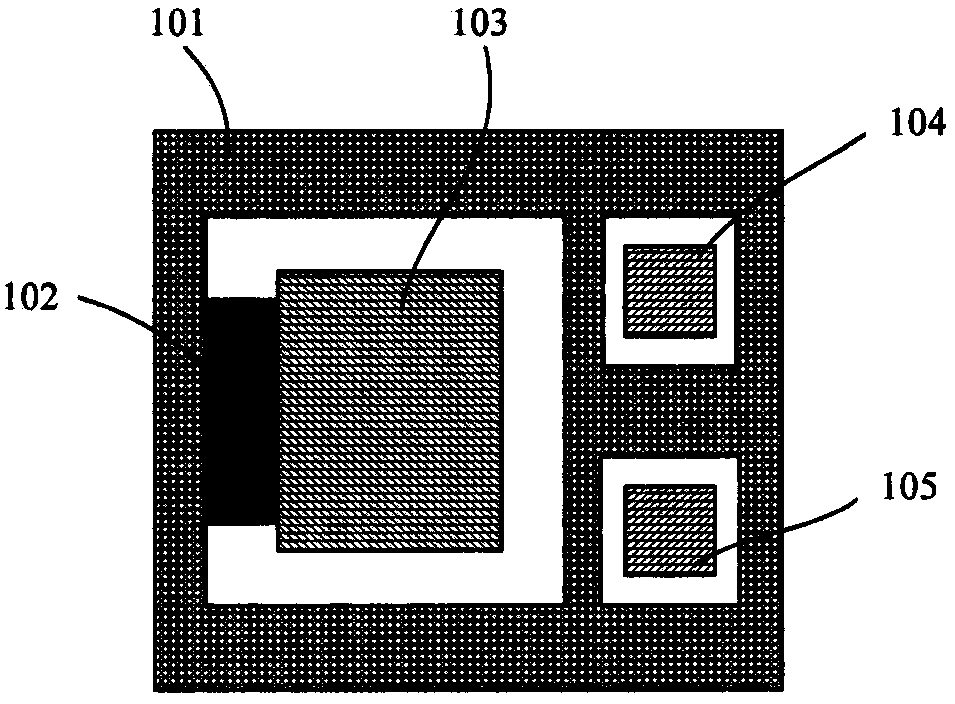

[0040] FIG. 1 is a schematic structural diagram of a silicon layer 1 of a MEMS accelerometer according to the present invention. The silicon layer 1 includes a silicon frame 101 , a proof mass 103 , a support beam 102 , and silicon islands 104 and 105 . The mass block 103 is formed inside the silicon frame 101 , one end of the mass block 103 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com