Optimization design method for extreme ultraviolet lithographic projection objective lens

A technology of extreme ultraviolet lithography and projection objective lens, which is applied in the direction of microlithography exposure equipment, optics, optical components, etc., and can solve problems such as inability to guarantee optical performance and blind design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] First of all, it needs to be declared: the ray tracing and damped least squares method in the optimization step of the present invention can be realized by using commercial optical design software CODEV and zemax, and the implementation example of the present invention is realized by using the optical design software CODEV.

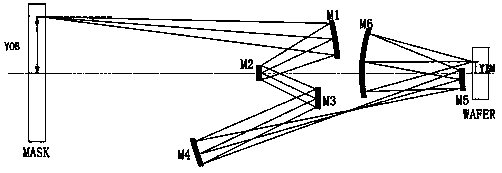

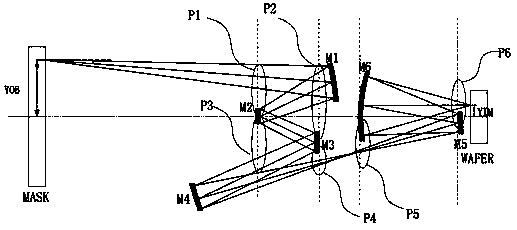

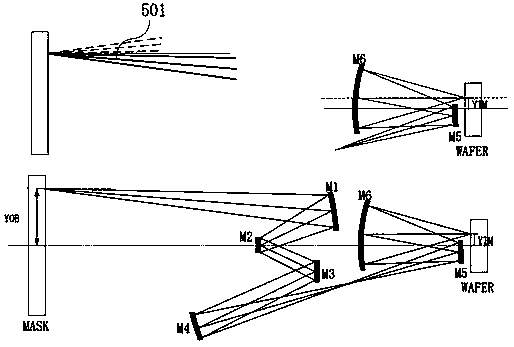

[0054] The EULV projection objective adopts the design of coaxial components and off-axis field of view. The field of view is an off-axis annular field of view, that is, a part of a concentric ring with the center on the optical axis, the field of view width FW is 1-2mm, the chord length CL is 26mm, and the chord angle is less than or equal to 60°, such as figure 2 As shown, there are four field of view points evenly distributed on the width of the field of view on the meridian plane, among which F1 is the highest field of view point, F4 is the lowest field of view point, and there are two lowest field of view points outside the meridian plane, bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com