Method for manufacturing flexible display and substrate for manufacturing flexible display

The technology of a flexible display and its manufacturing method is applied in the manufacture of flexible displays and in the field of substrates for flexible displays, and can solve problems such as unclean peeling of amorphous silicon thin film germanium oxide films, damage to flexible substrates, unfavorable flexible displays, etc., to achieve Accelerate the isotropic chemical reaction, accelerate the speed of stripping, and avoid the effect of performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

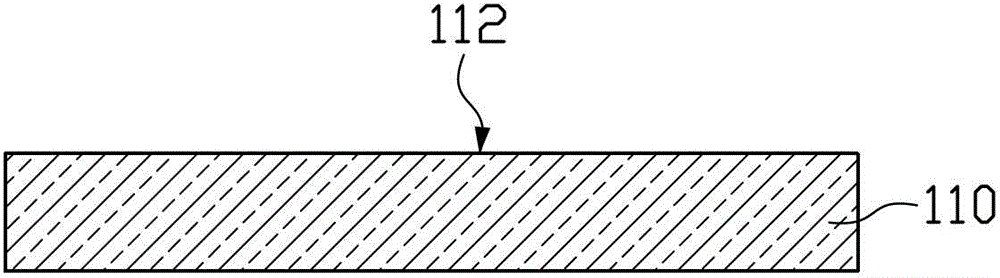

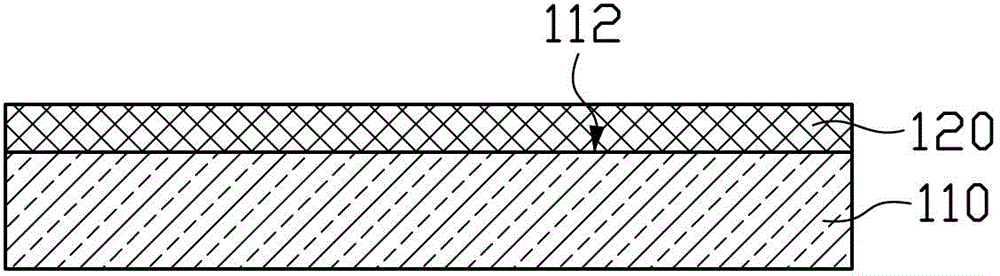

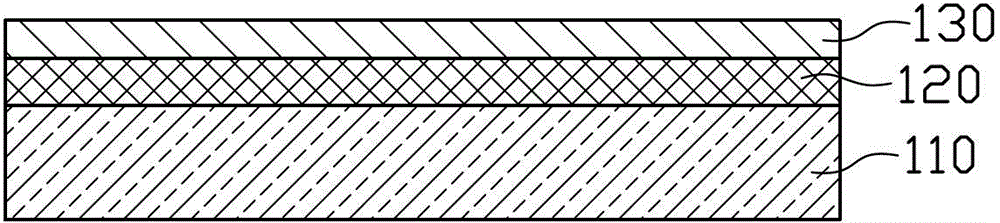

[0017] Figure 1A to Figure 1G It is a schematic flow chart of the manufacturing method of the flexible display according to the first embodiment of the present invention. First, see Figure 1A to Figure 1E , which is the manufacturing process of the substrate 100 for the flexible display. In this embodiment, the FOLED display is taken as an example, and the substrate 100 for making the flexible display is shown as a FOLED panel unit. That is to say, the substrate 100 for making the flexible display can finally form an independent flexible display such as a FOLED display.

[0018] see Figure 1A , providing a rigid substrate 110 . In this embodiment, the rigid substrate 110 is, for example, a quartz substrate or a glass substrate, but is not limited thereto. The rigid substrate 110 is mainly used to provide support during the subsequent manufacturing process of circuits and display elements, so as to prevent the flexible substrate from being broken, wrinkled and deformed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com