Crystal filter for wet-process phosphoric acid concentrating device

A concentration device, wet-process phosphoric acid technology, applied in the direction of fixed filter elements, filtration separation, phosphorus compounds, etc., can solve the problems of concentration system fouling, increase of outlet pressure, deviation of filtration effect, etc., to achieve extended service life, High filtration efficiency and convenient slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

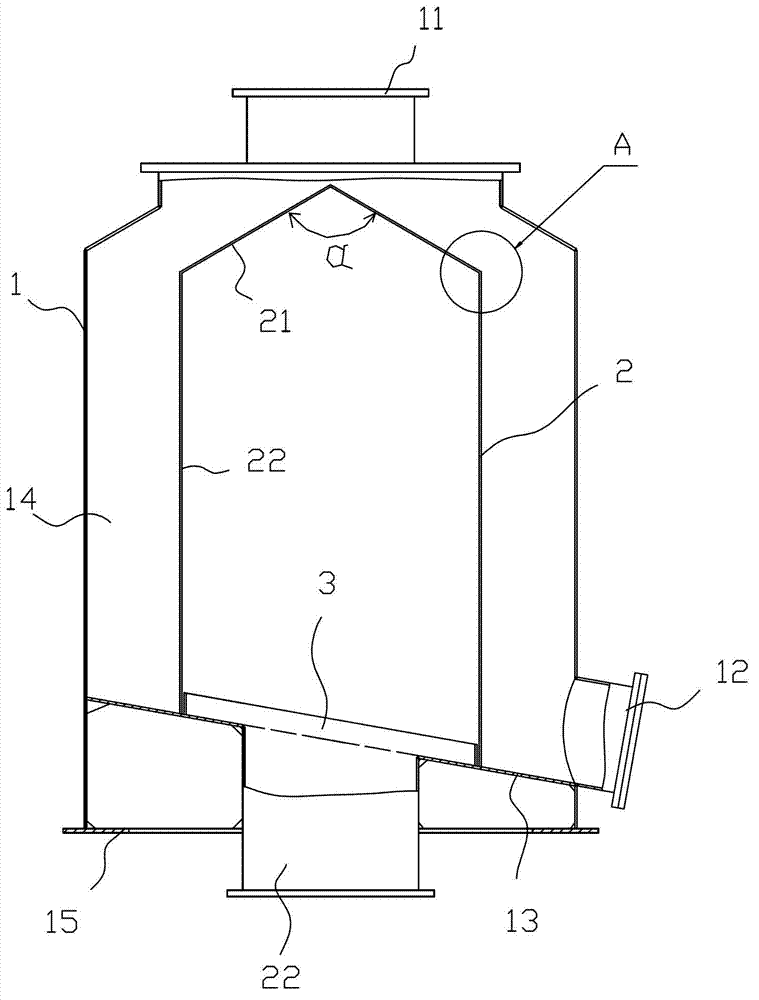

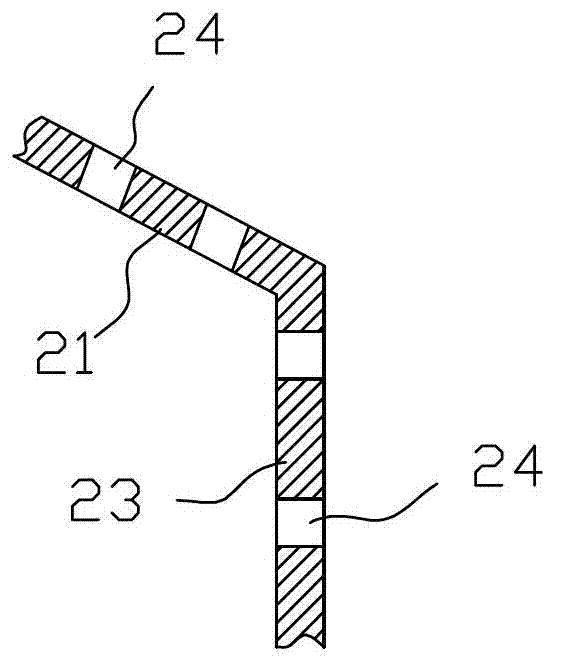

[0012] The structure of the present invention is as figure 1 and figure 2 As shown, it includes a cylinder body 1, a cylindrical filter element 2 placed in the cylinder body, and an annular channel 14 is formed between the cylindrical side wall of the filter element 2 and the side wall of the cylinder body 1; the top 21 of the filter element 2 is conical, and the conical top of the filter element 21 and the side wall 23 are provided with a filter hole 24 with an aperture of 25-55mm, and the bottom of the filter element 2 is provided with a liquid outlet 22 leading to the outside of the cylinder 1; the cylinder 1 is provided with a liquid inlet above the conical top 21 of the filter element 11. The bottom wall 13 of the inner cavity of the cylinder body 1 is inclined, and a slag discharge port 12 is provided on the cylinder wall at the low point of the inclined bottom wall 13 of the cylinder inner cavity. The lower end of the cylinder body 2 is also provided with a horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com