Manufacturing method of vacuum external applied load insulation board

A manufacturing method and technology of thermal insulation board, which can be applied to manufacturing tools, ceramic molding machines, etc., can solve the problems of increased operating costs, easy air leakage, increased thermal conductivity, etc. The effect of coefficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

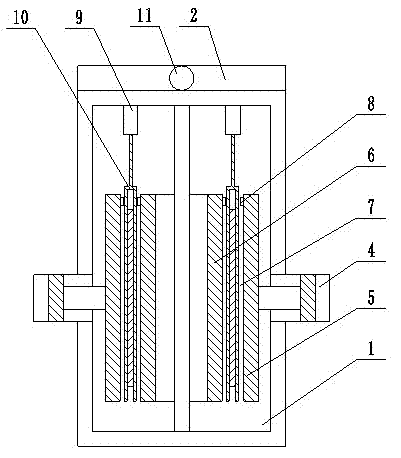

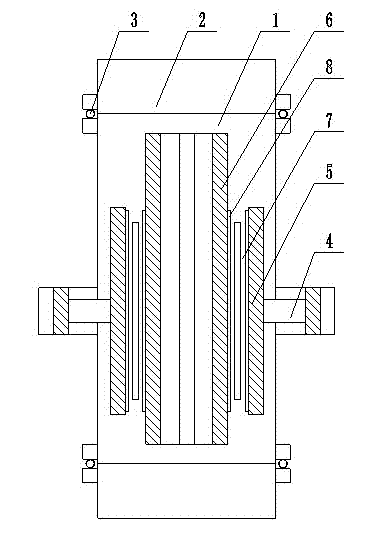

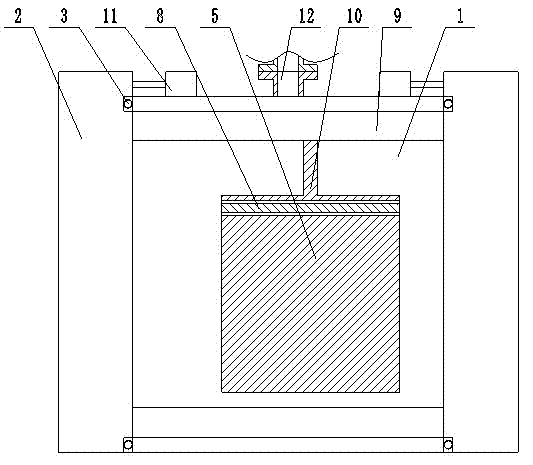

[0040] Such as figure 1 , figure 2 , image 3 As shown, a method for manufacturing a vacuum external load insulation panel of the present invention is carried out according to the following steps:

[0041] The first step is to send the thermal insulation material into the material silo, put the powder forming square box into the PE layer aluminum foil composite film bag, and set a layer of filter material at the opening of the PE layer aluminum foil composite film bag;

[0042] In the second step, use the first clamp to clamp the PE layer aluminum foil composite film bag in the first step except the other three sides of the opening side and transport the clamped PE layer aluminum foil composite film bag to the shaping machine, and then use The template of the shaping machine presses the PE layer aluminum foil composite film bag;

[0043] The third step is to use the spring screw conveyor to measure and output the thermal insulation material from the material silo in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com