Method for synthesizing vinylacetylene through acetylene dimerization

A technology of vinyl acetylene and acetylene di, which is applied in the field of chemical process intensification, can solve the problems of complex process, high production cost, and low vinyl acetylene selectivity of single-pass conversion of acetylene, and achieve high catalytic activity, low price and high inhibition The effect of polymer formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

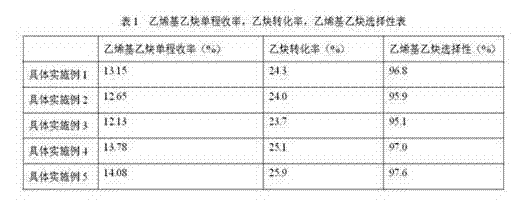

Examples

specific Embodiment 1

[0019] ① Dissolve 0.3 kmol ammonium chloride and 0.1 kmol urea in a small amount of water, and add them into a reactor with 45 L of water; 3 / h flow rate into the nitrogen exhaust air, at the same time, bubbling and stirring to fully dissolve the ammonium chloride and urea;

[0020] ② Keep the reaction temperature at 70~90°C, continue to pass nitrogen gas to evacuate and stir for 30 minutes by bubbling, then add 0.3 kmol of cuprous chloride and 0.3 L of concentrated hydrochloric acid in sequence; the content of cuprous chloride is ≥97 % cuprous chloride, the mass percentage concentration of described hydrochloric acid is 37%~38%;

[0021] ③Keep the reaction temperature at 70~90℃, continue to pass nitrogen gas to evacuate and stir with bubbling. After the cuprous chloride is fully dissolved, replace the nitrogen with acetylene, and the flow rate of acetylene is controlled at 280~320 Nm 3 / h, keep the reaction temperature at 70~90°C, and stir with bubbling to make the dimerizat...

specific Embodiment 2

[0023] ① Dissolve 0.24 kmol of ammonium chloride and 0.08 kmol of urea in a small amount of water and add to a reactor containing 45 L of water; 3 / h flow rate into the nitrogen exhaust air, at the same time, bubbling and stirring to fully dissolve the ammonium chloride and urea;

[0024] ② Keep the reaction temperature at 70~90°C, continue to pass nitrogen gas to evacuate and stir for 30 minutes, then add 0.3 kmol cuprous chloride and 0.3 L concentrated hydrochloric acid; the cuprous chloride is ≥97% Cuprous chloride, the mass percentage concentration of described hydrochloric acid is 37%~38%;

[0025] ③Keep the reaction temperature at 70~90℃, continue to pass nitrogen gas to evacuate and stir with bubbling. After the cuprous chloride is fully dissolved, replace the nitrogen with acetylene, and the flow rate of acetylene is controlled at 280~320 Nm 3 / h, keep the reaction temperature at 70~90°C, and stir with bubbling to make the dimerization of acetylene to obtain vinyl ace...

specific Embodiment 3

[0027] ① Dissolve 0.18 kmol of ammonium chloride and 0.06 kmol of urea in a small amount of water, and add to a reactor equipped with 45 L of water; 3 / h flow rate into the nitrogen exhaust air, at the same time, bubbling and stirring to fully dissolve the ammonium chloride and urea;

[0028] ② Keep the reaction temperature at 70~90°C, continue to pass nitrogen gas to evacuate and stir for 30 minutes, then add 0.3 kmol cuprous chloride and 0.3 L concentrated hydrochloric acid; the cuprous chloride is ≥97% Cuprous chloride, the mass percentage concentration of described hydrochloric acid is 37%~38%;

[0029] ③Keep the reaction temperature at 70~90℃, continue to pass nitrogen gas to evacuate and stir with bubbling. After the cuprous chloride is fully dissolved, replace the nitrogen with acetylene, and the flow rate of acetylene is controlled at 280~320 Nm 3 / h, keep the reaction temperature at 70~90°C, and stir with bubbling to make the dimerization of acetylene to obtain vinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com