Preparation method for cinnamaldehyde surface molecularly imprinted polymer

A surface molecular imprinting and molecular imprinting technology, which is applied in material separation, analytical materials, ion exchange, etc., can solve the problems of cumbersome preparation methods, unstable column efficiency, uneven particle size, etc., and achieve simple and easy preparation process, molecular Strong identification ability and uniform grinding particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

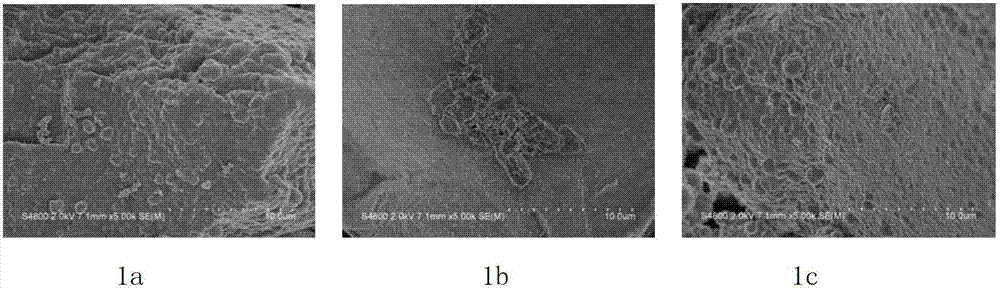

[0023] Example 1 Preparation of Cinnamaldehyde Surface Molecularly Imprinted Polymer

[0024] 1. Activation of silica gel

[0025] Dissolve 10g gelatin in 100ml0.25mol / L NaOH, shake for 30min, vacuum filter and wash until neutral, then dissolve it in 200ml8mol / LHCl, stir and reflux at 90°C for 12h, wash with ultrapure water until neutral, then vacuum dry, Obtain activated silica gel.

[0026] 2. Alkylated silica gel

[0027] Activated silica gel and silylating agent 3-methoxyaminopropylsilane were stirred and refluxed in toluene solution at 90°C for 12 hours, washed and vacuum-dried to obtain alkylated silica gel;

[0028] 3. Preparation of polymer

[0029] Take 1 g of alkylated silica gel, 1 mmol of cinnamic acid, 8 mol of methacrylic acid, 5 mol of ethylene glycol dimethacrylate, and 0.20 mmol of azobisisobutyronitrile, dissolve them in 50 ml of chloroform by volume, and mix them well in 60 ℃ water bath shaking thermal polymerization for 48h;

[0030] 4. Washing of temp...

Embodiment 2

[0032] Example 2 Application of Cinnamaldehyde Surface Molecularly Imprinted Polymer

[0033] 1. Column packing and activation of solid phase extraction column

[0034] Take an empty polypropylene solid-phase extraction column with a capacity of 3ml, add a sieve plate of appropriate size, weigh 250mg of cinnamaldehyde molecularly imprinted solid-phase extraction material (MIPs) into it, and then add a sieve plate to the top of the packing, and use a sieve plate to Press the plate insertion tool tightly, and take 5ml of water-activated solid-phase extraction column;

[0035] 2. Sample pre-extraction

[0036] Cosmetic samples were ultrasonically extracted by adding methanol, and then filtered with a 0.22 μm microporous membrane.

[0037] 3. Sample loading, rinsing, elution and drying to volume

[0038]Add the above sample extract into the column, and control the solution passing through the column at a speed of no more than 0.5ml / min. After all the solution flows out, rinse t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com