Polytetrafluoroethylene modified asphalt waterproof coiled material and preparation method thereof

A technology of polytetrafluoroethylene and modified asphalt, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of low tensile strength, poor bonding performance, and poor weather resistance of asphalt, and achieve large friction coefficient and deformation Strong adaptability and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Recipe and preparation method:

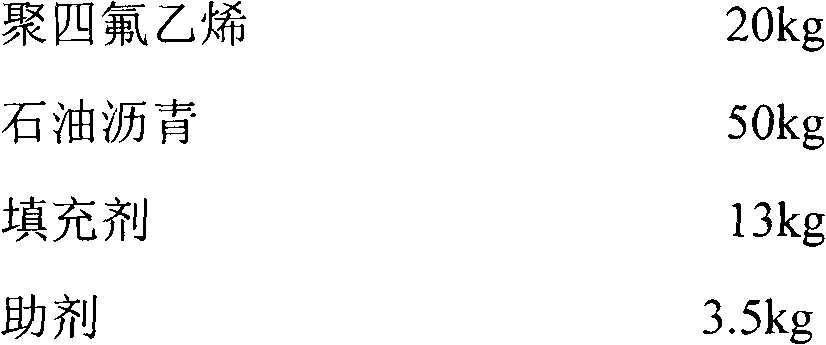

[0024] 1. Formulation:

[0025]

[0026] 2. Preparation method:

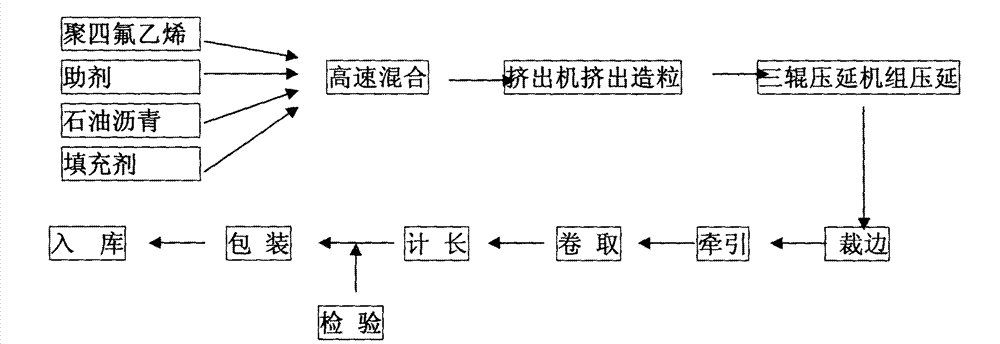

[0027] (1) Measure all the raw materials according to the formula ratio and put them into the high-speed mixer for mixing evenly, then put them into the hopper of the twin-screw extruder, and follow the instructions in the accompanying drawings figure 1 The technical process for the preparation of PTFE modified bitumen waterproofing membrane is extrusion granulation.

[0028] (2) Throw the prepared polytetrafluoroethylene modified bitumen pellets into the barrel of the extruder calendering unit for extrusion and calendering to make polytetrafluoroethylene modified bitumen waterproofing membrane.

[0029] The main properties of the polytetrafluoroethylene modified asphalt waterproof membrane prepared by the present invention:

[0030] serial number

[0031] 4

Embodiment 2

[0033] formula:

[0034]

[0035] Preparation method is identical with embodiment 1

Embodiment 3

[0037]

[0038] Preparation method is identical with embodiment 1

[0039] The measured performance comparison table of three kinds of embodiments

[0040] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com