Desulfurization chimney anticorrosive paint and preparation method thereof

A technology for anti-corrosion coatings and chimneys, applied in anti-corrosion coatings, coatings, etc., to achieve the effects of corrosion resistance to flue gas condensate, excellent stress and strain resistance, and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

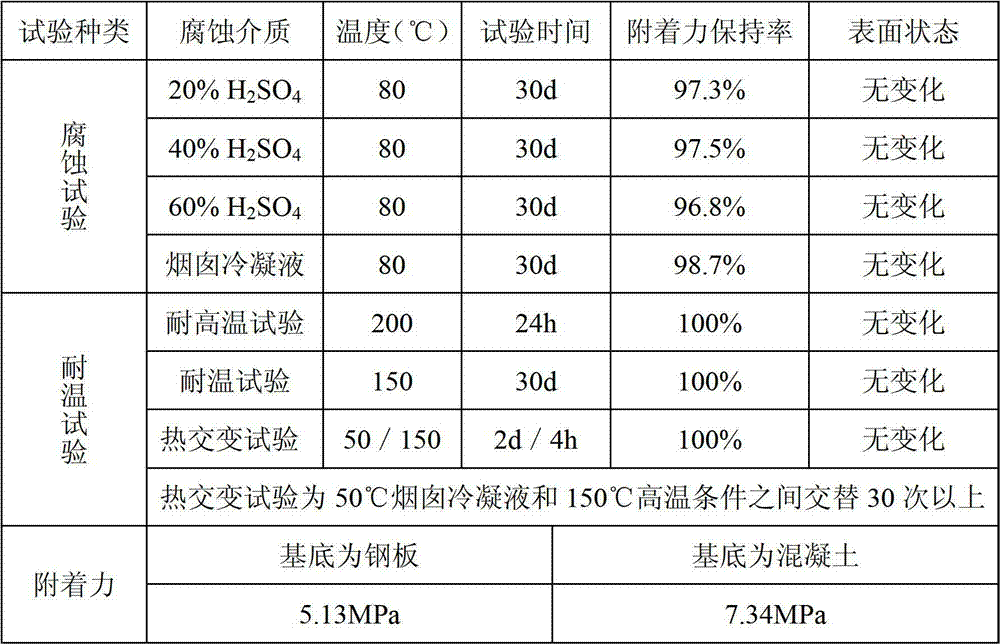

Embodiment 1

[0042] 1) Preparation of component A:

[0043] First, crush vinylidene fluoride copolymer, the raw material of fluoroelastomer, to a particle size of less than 1 cm, then mix, stir and dissolve it with solvent acetone at a mass ratio of 1:0.5 for 72 hours to obtain a fluoroelastomer solution, and then press it into the fluoroelastomer solution Fluoroelastomer raw material: filler (glass flakes with a size of 120 mesh to 400 mesh) at a mass ratio of 1:0.1. After adding filler, disperse, grind and refine for 10 hours, and finally press fluoroelastomer raw material: additive magnesium oxide at a ratio of 1:0.005 The mass ratio is made into component A by adding additives, dispersing and grinding for 4 hours;

[0044] 2) Preparation of component B:

[0045] Mix the curing agent and the solvent acetone at a ratio of 1:1, dissolve and disperse for 1 hour to obtain component B;

[0046] 3) Stir and mix component A and component B at a mass ratio of 1:0.001 for 10 minutes to obtain ...

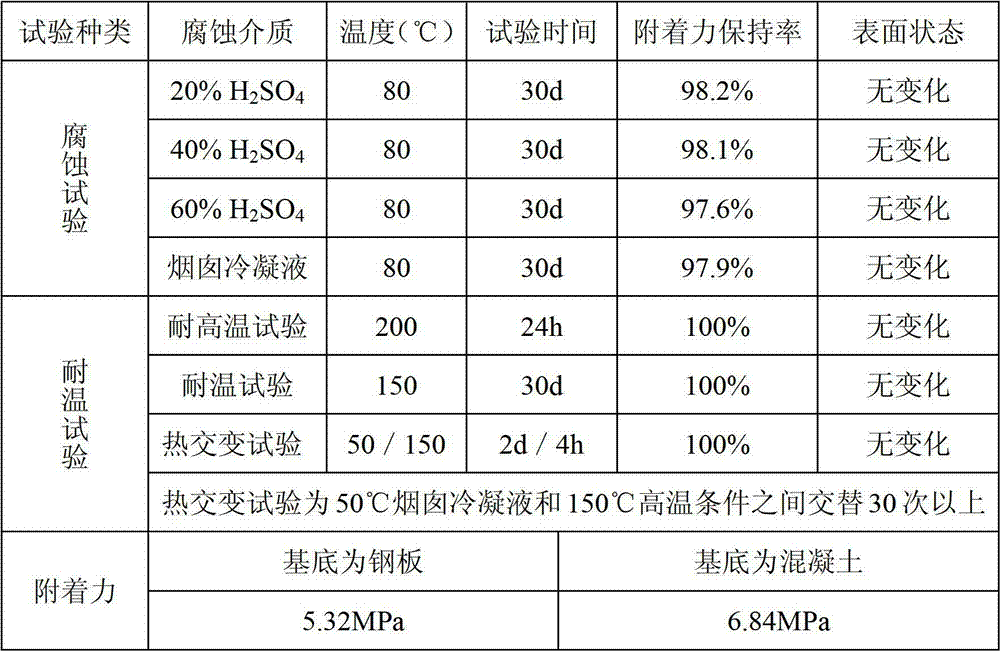

Embodiment 2

[0051] 1) Preparation of component A:

[0052] First, pulverize the tetrafluoroethylene copolymer as the raw material of the fluoroelastomer to a particle size below 1 cm, then mix and stir it with the solvent cyclohexanone at a mass ratio of 1:2 and dissolve for 40 hours to obtain a fluoroelastomer solution, and then add the fluoroelastomer solution to the fluoroelastomer solution According to the mass ratio of fluoroelastomer raw material: filler (hollow glass microspheres with a size of 120 mesh to 400 mesh) at a mass ratio of 1:0.3, add the filler, disperse and grind for 20 hours, and finally press fluoroelastomer raw material: additive phthalate The mass ratio is 1:0.01, adding auxiliary agents, dispersing, grinding and refining for 6 hours to make component A;

[0053] 2) Preparation of component B:

[0054] The curing agent phenethylamine and the solvent cyclohexanone were mixed, dissolved and dispersed for 8 hours at a ratio of 1:1 to obtain component B;

[0055] 3) ...

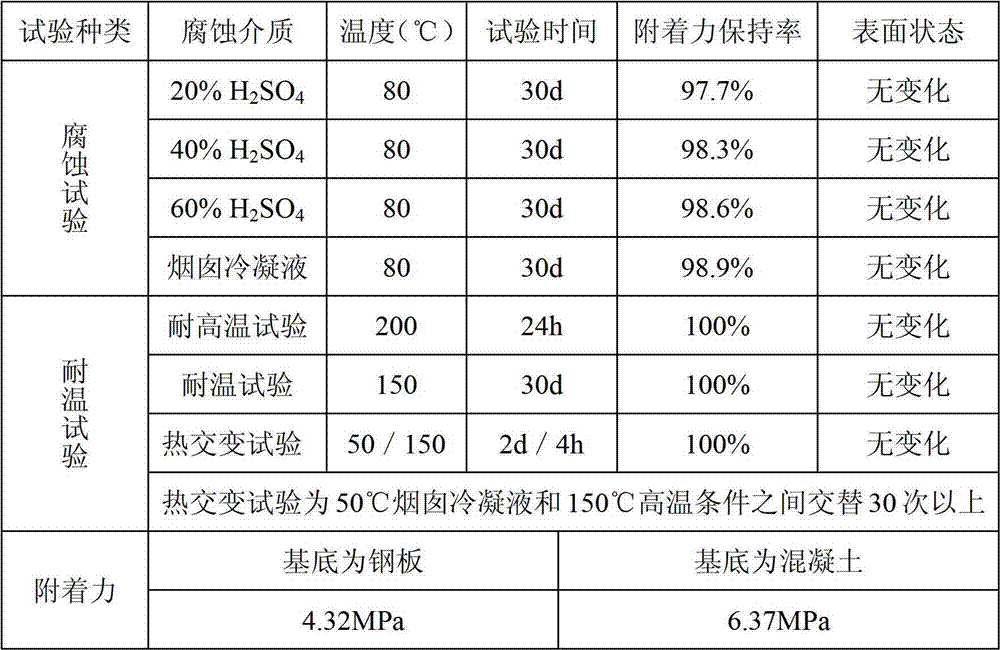

Embodiment 3

[0060] 1) Preparation of component A:

[0061] Firstly, the fluoroelastomer raw material perfluorovinyl ether copolymer is pulverized to a particle size of less than 1 cm, then mixed with ethyl acetate as a solvent in a mass ratio of 1:5, stirred and dissolved for 1 hour to obtain a fluoroelastomer solution, and then to the fluoroelastomer In the body solution, the mass ratio of fluoroelastomer raw material: filler (titanium dioxide of type R902) is 1:0.5. After adding the filler, it is dispersed and ground for 36 hours, and finally the raw material of fluoroelastomer: auxiliary agent polyacrylate is 1: The mass ratio of 0.015 is added into the auxiliary agent to disperse and grind for 10 hours to make component A;

[0062] 2) Preparation of component B:

[0063] Mix, dissolve and disperse the curing agent octadecyltrimethylammonium chloride and the solvent ethyl acetate at a ratio of 1:1 for 5 hours to obtain component B;

[0064] 3) Stir and mix component A and component B a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com