High-temperature powder retarder in oil well cement

An oil well cement, medium and high temperature technology, applied in drilling compositions, chemical instruments and methods, etc., to achieve the effects of stable chemical properties, easy adjustment of thickening time, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

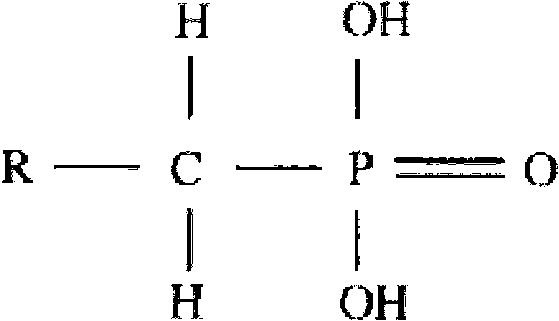

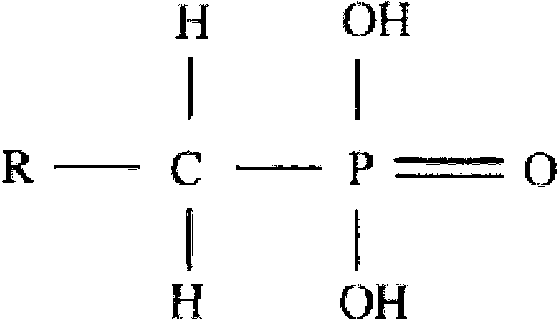

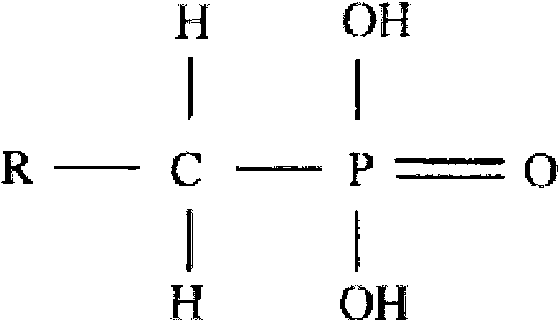

Method used

Image

Examples

Embodiment 1

[0029] Weigh 1 part by weight of methylene phosphate, 0.10 part of citric acid, 0.05 part of tartaric acid and 0.20 part of gluconic acid, and then mix them uniformly in a mortar to make a medium-high temperature powder retarder, use R01 as code name.

[0030] Mix the cement slurry performance of this retarder under the different test conditions of table 1

[0031]

Embodiment 2

[0033] Weigh 1 part by weight of subunit phosphate, 0.20 part of citric acid, 0.10 part of tartaric acid and 0.10 part of gluconic acid, and then mix them evenly in a mortar to make a medium-high temperature powder retarder, and use R02 as the code name .

[0034] Mix the cement slurry performance of this retarder under the different test conditions of table 2

[0035]

[0036]

Embodiment 3

[0038] Weigh 1 part of subunit phosphate, 0.20 part of citric acid, 0.05 part of tartaric acid and 0.15 part of glucose, and then mix them uniformly in a mortar to make a medium-high temperature powder retarder, and use R03 as the code name.

[0039] Mix the cement slurry performance of this retarder under the different test conditions of table 2

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com