Light cable plate strip for power system and preparation method of light cable plate strip

A technology for power systems and cables, applied in the field of light cable strips and preparation, can solve problems such as inconvenience in engineering construction and self-weight of monomers, and achieve the effects of being beneficial to on-site construction, reducing production costs, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

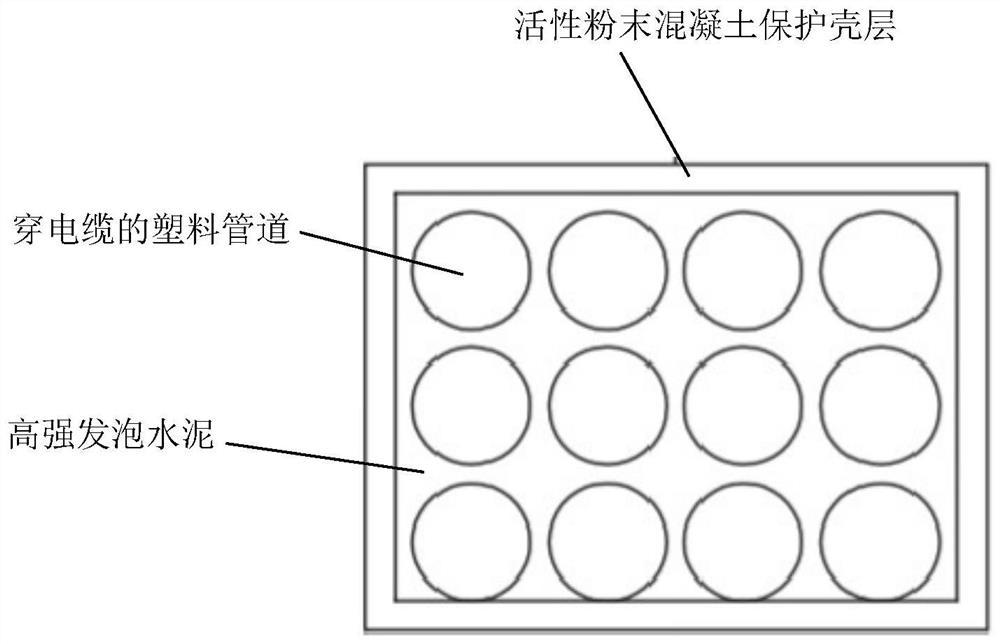

[0028] combine figure 1 , a kind of light-duty cable strip for power system proposed by this embodiment is composed of high-strength and high-toughness active powder concrete protective shell, high-strength foamed cement core material and plastic pipes fixed inside the core material to pass through the cable. . in:

[0029] The high-strength foamed cement mentioned above has a compressive strength of not less than 5MPa and a bulk density of not more than 800Kg / m 3 . The high-strength foamed cement has a ratio (quality) of: cement: fly ash: silica fume: composite air-entraining agent is 0.6-0.8: 0.1-0.3: 0.1-0.3: 0.001-0.002; wherein the cement is 52.5 Silicon cement, fly ash is grade 1 ash, silica fume is grade 90, and the composite air-entraining agent is animal protein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com