Bottom sediment active covering system and method for controlling sedimentary phosphate release

A phosphorus release and sediment technology, applied in chemical instruments and methods, sludge treatment, river regulation, etc., can solve the problems of reduction effect, slow fixation rate, and unsatisfactory efficiency, and achieve reduction of phosphorus release and fixation rate Fast, fast and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

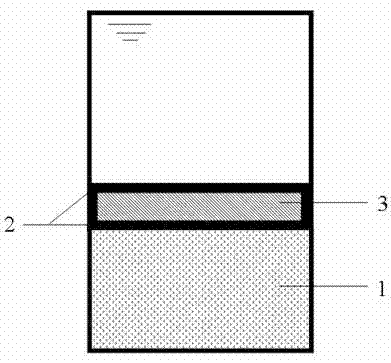

[0025] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a bottom mud active covering system for controlling the release of bottom mud phosphorus in the present invention. The bottom mud active covering system is provided with two layers of geotextiles 2, and a layer of bottom mud covering material layer 3 is arranged between the two layers of geotextiles 2, and the bottom mud covering material layer 3 is weight ratio A composition of calcite and hydroxyapatite of 5:1-1000:1, wherein the particle diameters of the calcite and hydroxyapatite are both 6 mesh to 600 mesh.

[0026] When in use, the bottom mud active covering system of the present invention can be spread directly on the bottom mud 1 .

[0027] It should be noted that the geotextile layer 2 is made of woven geotextiles and non-woven geotextiles. Since the geotextiles have excellent filtering, drainage, isolation, reinforcement, seepage prevention, and protection functions, they can protect...

Embodiment 2

[0029] 1. Firstly, hydroxyapatite was synthesized by solution precipitation method. 50 mL of 1mol / L Ca(NO 3 ) 2 solution with 30 mL of 1 mol / L (NH 4 ) 2 HPO 4 The solution was mixed with 0.8 mol / L NH 3 OH solution to adjust the pH to 9, then place the mixture in a shaker, shake it at a speed of 150 rpm for 48 hours, take the precipitate and wash it to neutral, dry it to obtain hydroxyapatite, and then crush it into a particle size of over 200 mesh particles. Repeat the above process 4 times, and collect all the hydroxyapatite samples for later use. Purchase calcite, crush the calcite, and sieve to obtain calcite with a particle size of over 300 mesh.

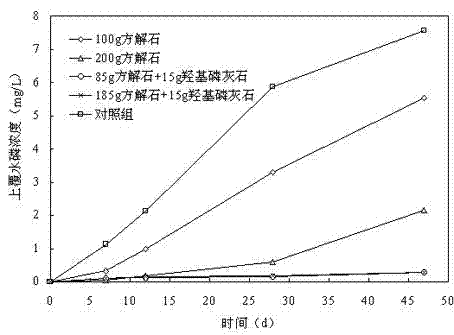

[0030] 2. Collect the surface sediment of polluted ponds. Weigh 1000 g of surface sediment and put them into three 2.5 L brown glass bottles, so that the thickness of the bottom mud in each brown glass bottle is about 6 cm. The sludge in each amber glass bottle was treated differently. The sediment in the first brown g...

Embodiment 3

[0033] 1. Firstly, hydroxyapatite was synthesized by solution precipitation method. 50 mL of 1 mol / L Ca(NO 3 ) 2 solution with 30 mL of 1 mol / L (NH 4 ) 2 HPO 4 The solution was mixed with 0.8 mol / L NH 3 OH solution to adjust the pH to 9, then place the mixture in a shaker, shake it at a speed of 150 rpm for 48 hours, take the precipitate and wash it to neutral, dry it to obtain hydroxyapatite, and then crush it into a particle size of over 200 mesh particles. Repeat the above process 4 times, and collect all the hydroxyapatite samples for later use. Purchase calcite, crush the calcite, and sieve to obtain calcite with a particle size of over 300 mesh.

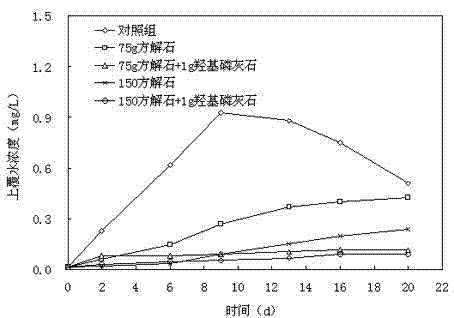

[0034] 2. Collect the surface sediment of polluted ponds. Weigh 1000 g of surface sediment and put them into three 2.5 L brown glass bottles, so that the thickness of the bottom mud in each brown glass bottle is about 6 cm. The sludge in each amber glass bottle was treated differently. The mud in the first brown glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com